- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Aviation aluminum fixing plate

Flatness: ≤ 0.05 mm / 1000 mm

Strength: Tensile Strength ≥ 524 MPa

Surface Treatment: Hard Anodizing (Film Thickness ≥ 25μm)

Hardness: Base Hardness ≥ HRB 87

Key Characteristics: Ultra-high strength, lightweight, wear-resistant

Support sample service

Support OEM,ODM customization

Delivery time: 10-20 working days

Certification: ISO9001:2015 , Complies with EU RoHS standards

Aviation Aluminum Fixing Plate - Precision Engineered for Superior Performance

Product Introduction

When you require dependable mounting arrangements for accuracy gear, our aviation aluminum fixing plate conveys unmatched execution and solidness. Fabricated from aerospace-grade 7075-T651 aluminum combination, this settling plate combines ultra-high quality with uncommon lightweight characteristics. You get the culminate adjust of auxiliary judgment and weight diminishment for your requesting applications.

Our settling plates experience strict quality control forms. Each plate meets aviation industry benchmarks whereas giving cost-effective arrangements for your ventures. The progressed difficult anodizing treatment guarantees long-lasting execution in challenging situations. You can believe our items to keep up accuracy and unwavering quality all through their benefit life.

Main Advantages

Lightweight Aerospace-Grade Construction

You advantage from critical weight diminishment without compromising quality. Our plates weigh as it were one-third of comparable steel components whereas conveying predominant auxiliary performance.

Exceptional Heat Dissipation

The aluminum development gives amazing warm conductivity at 170W/(m·K). This include makes a difference ensure your delicate hardware from warm buildup amid operation.

Superior Strength-to-Weight Ratio

You get 3-5 times more grounded execution compared to standard aluminum sheets. This advantage makes our plates perfect for high-dynamic applications and robotized generation lines.

Advanced Surface Protection

Our difficult anodizing handle makes a defensive layer that stands up to erosion and wear. You appreciate expanded benefit life and diminished upkeep requirements.

Specifications

| Parameter | Value |

|---|---|

| Material | 7075-T651 Aviation Aluminum |

| Flatness | ≤ 0.05 mm / 1000 mm |

| Tensile Strength | ≥ 524 MPa |

| Surface Treatment | Hard Anodizing (≥ 25μm) |

| Base Hardness | ≥ HRB 87 |

| Surface Hardness | ≥ HV 400 |

| Salt Spray Resistance | ≥ 1000h |

| Thermal Conductivity | 170W/(m·K) |

| Delivery Time | 10-20 working days |

Why Choose Us?

15 Years of Manufacturing Excellence

Since 2011, we have built a reputation for delivering precision-engineered components. Our team includes professionals from Singapore's top enterprises, ensuring world-class quality standards.

Cost-Effective Solutions

You save 30-40% on costs through our China supply chain advantages. We maintain competitive pricing without compromising quality or service standards.

Research and Development Focus

Our R&D investment represents 8% of annual revenue. With 36% of our staff dedicated to research, we continuously innovate to meet your evolving needs.

Proven Track Record

We hold 22 patents and maintain strong partnerships with global industry leaders. Our ISO9001:2015 certification demonstrates our commitment to quality management.

Customization Process

Step 1: Requirements Analysis

Share your specific dimensions, tolerances, and application requirements with our technical team.

Step 2: Design Optimization

We review your specifications and suggest improvements to enhance performance and reduce costs.

Step 3: Sample Production

You receive samples for testing and approval before full production begins.

Step 4: Manufacturing

Our lean production system ensures consistent quality and on-time delivery.

Step 5: Quality Inspection

Each aviation aluminum fixing plate undergoes comprehensive testing before shipment.

Factory Strength

Our comprehensive office specializes in accuracy instrument parts and CNC machining. Progressed generation hardware and accuracy testing disobedient ensure reliable quality from plan to delivery.

We work beneath a well-established incline generation framework. This approach empowers us to keep up productive workflows whereas guaranteeing each item meets your correct specifications.

Quality Certification

We keep up ISO9001:2015 Quality Administration Framework certification. All items comply with EU RoHS measures, guaranteeing natural obligation and administrative compliance.

Our strict quality control forms confirm fabric properties, dimensional precision, and surface wrap up quality. You get items that reliably meet or surpass industry standards.

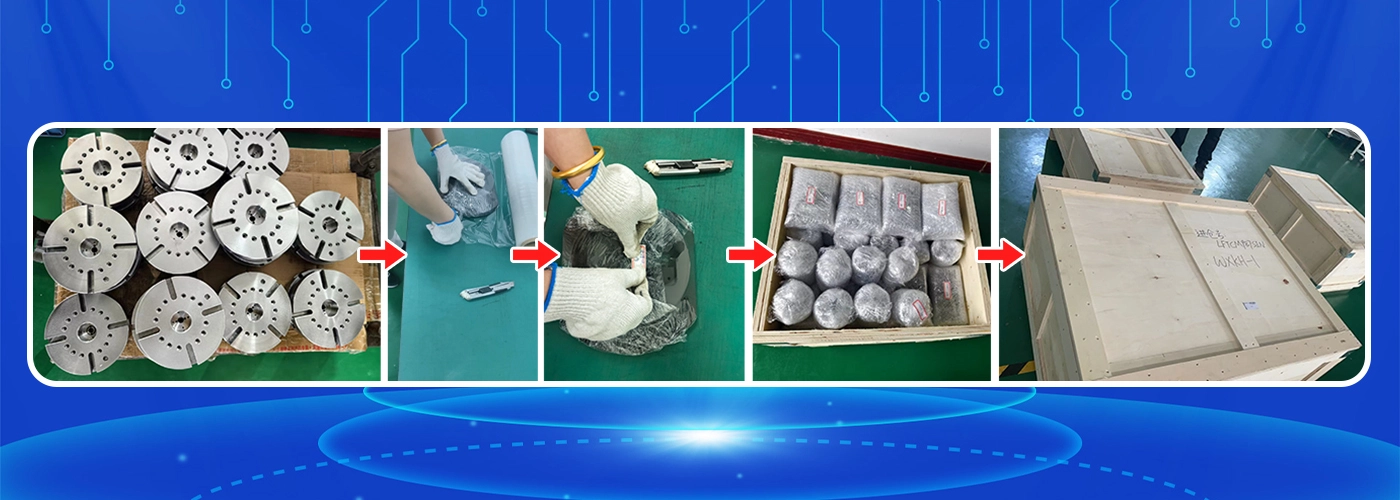

Transport Packaging

Your Flying aluminum settling plate arrives securely through our defensive bundling framework. We utilize shock-resistant materials and custom bundling to avoid harm amid transportation.

Standard bundling incorporates dampness security and secure situating to keep up item keenness. Extraordinary bundling choices are accessible for delicate or high-value shipments.

FAQ

Q: How does this compare to steel fixing plates?

A: Our aluminum plates offer equivalent strength at one-third the weight, plus superior corrosion resistance and better heat dissipation.

Q: Can you handle custom dimensions?

A: Yes, we provide full OEM/ODM customization services. Our team works with you to optimize designs for your specific applications.

Q: What's the minimum order quantity?

A: We accommodate both prototype quantities and large production runs. Contact us to discuss your specific requirements.

Q: How do you ensure dimensional accuracy?

A: Our flatness tolerance of ≤ 0.05 mm per 1000 mm is maintained through precision machining and comprehensive quality inspection.

Contact Us

Ready to enhance your projects with premium aviation aluminum fixing plate solutions? Our technical team stands ready to assist with your requirements.

Email: service@kaihancnc.com

We provide comprehensive technical consulting support and quick response times for all inquiries. Let us help you find the perfect mounting solution for your application needs.

Learn about our latest products and discounts through SMS or email