- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

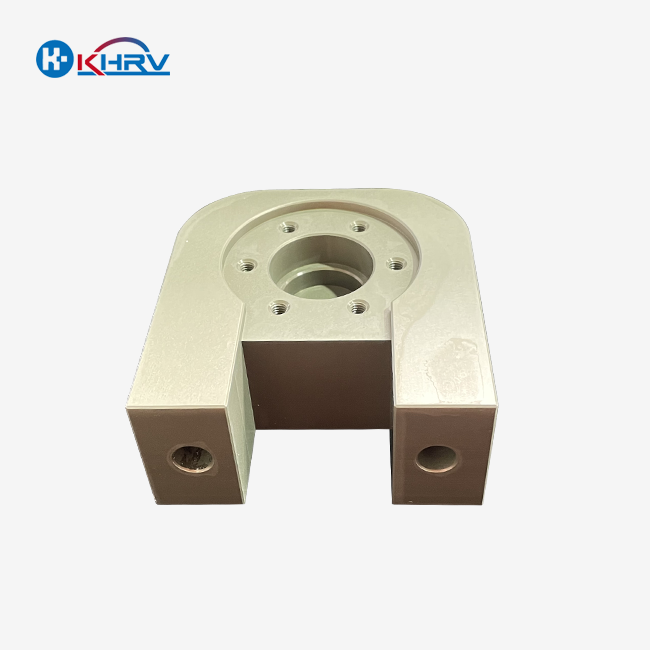

Brass Machined Parts manufacturer

Precision Brass Machining for Global Industries

Wuxi Kaihan Technology Co. , Ltd.

makes quality Brass Machined Parts for automotive, industrial, and electronics customers worldwide.

CNC machining achieves micron-level accuracy and strict industrial standards.

Every item is made of ISO and RoHS-certified materials for durability and performance.

For prototypes or bulk production, we customize our services.

Fast-turn prototyping speeds product launches and lowers downtime.

We prioritize easy communication from design optimization to delivery as a trusted Brass Machined Parts manufacturer.

Over 80% of repeat clients like our consistency and responsiveness.

Work with a customer-focused tech team.

Our inventiveness and dependability are everywhere.

Wuxi Kaihan Technology: Precision Engineers Wuxi

Kaihan Technology, founded in 2011 in Jiangsu, China, combines innovation and modern production. The firm specializes in CNC tool development and precision component processing with 15 years of experience.

Innovative Solutions for Global Industries Leading Singaporean professionals lead R&D with 22 patents and lean manufacturing.

Engineering research employs almost one-third of the workforce, enabling customized multi-material semi-finishing and OEM solutions.

## Quality and Cost CNC tools and precise components are affordable and satisfy industrial requirements.

Partnering with global leaders emphasizes reliability and technological expertise.

Industry leaders trust Waste is reduced and output quality is maintained with lean manufacturing.

Each product is built to last, be accurate, and integrate into complicated systems.

Solution integrate innovation and engineering practice.

Precision Brass Machining for Modern Industries

Material science and excellent production skills are needed for high-quality brass machined components. Our team has over a decade of experience making automotive, electronics, and medical device components to tight tolerances.

Tailored Precision for Complex Designs Technical expertise and creativity are needed to make custom brass parts.

CNC machining ensures dimensional accuracy even for high-volume orders with complicated geometries.

To meet project needs, we customize procedures from prototype to production.

Material Mastery Matters Brass alloys are corrosion-resistant and electrically conductive, although handling affects performance.

Our application-specific grades like C36000 and C37700 optimize machinability and durability.

Starting with raw material inspection and ending with packing, strict quality checks ensure uniformity.

Applications across industries Brass components are versatile.

Plumbing fittings use corrosion resistance, whereas electrical hookups use conductivity.

Medical equipment makers trust our accuracy for sanitary, dependable parts.

Fast turnaround and scalable solutions keep projects on schedule.

**Quality Beyond Standards** ISO-certified methods guarantee traceability and compliance.

Surface finishes, thread integrity, and pressure tolerance are extensively evaluated.

Partnering with us means buying durable parts.

Every brass machined item transforms basic materials into solutions that fuel global industries via innovation and reliability.

FAQs

1. What makes Wuxi Kaihan Technology a reliable brass machined part manufacturer?

Our specialization is precision brass machining with over a decade of experience. CNC technology, ISO-certified quality control, and skilled engineers create durable, high-tolerance components to your requirements.2. How do you maintain brass component quality?

Dimensional and material tests are performed on every brass machined item. Our superior brass alloys and global certifications provide corrosion resistance, lifespan, and performance.3. Can you make bespoke brass machined components for certain applications?

Customization is available from prototype to mass orders. Provide design parameters or let us improve your idea. We customize solutions for automotive, plumbing, and electronics.4. What industries use your brass machining services?

HVAC, electrical connections, marine hardware, and industrial machines use our products. Brass is perfect for precision-driven, high-stress settings because to its conductivity and durability.5. Why select your firm as my brass parts manufacturer?

We provide affordable price, rapid turnaround, and full support. We are trustworthy due to our track record and client-focused approach. Ready to talk project? Request a quote today!

Best Selling Products

Related Blogs

Related Search

Telephone:+8615951511692

Email:service@kaihancnc.com

Learn about our latest products and discounts through SMS or email