- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

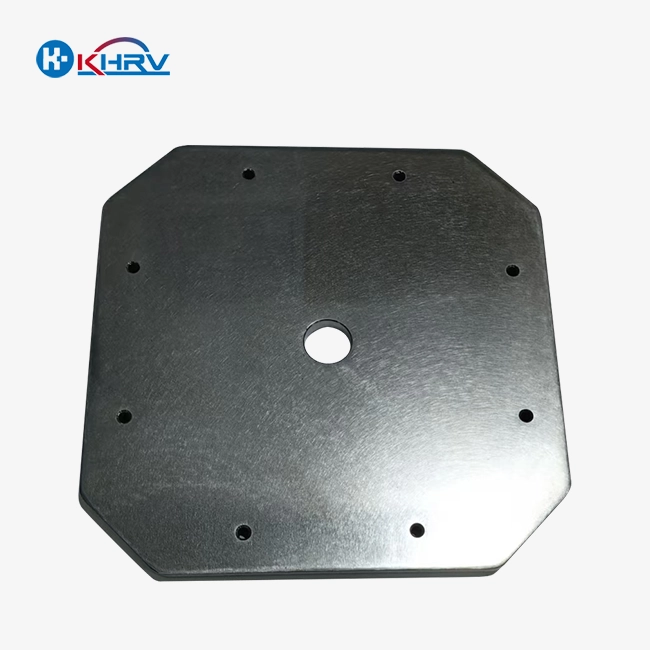

PPS Insulating protective enclosure

Insulation strength: >20kV/mm

Support sample service

Support OEM,ODM customization

Delivery time: 10-20 working days

Certification: ISO9001:2015 , Complies with EU RoHS standards

PPS Insulating Protective Enclosure - Professional Solution for Semiconductor Applications

Product Introduction

When you require dependable electrical security for semiconductor gear, our PPS insulating protective enclosure in area conveys remarkable execution. Fabricated utilizing premium PPS (Polyphenylene sulfide) building plastic, this committed lodging secures control feedthrough components in semiconductor gadgets. You'll advantage from prevalent electrical separator, tall temperature resistance, and chemical erosion security. Our walled in areas give separator quality surpassing 20kV/mm, making them idealize for requesting cleanroom situations. With 15 a long time of fabricating skill, we guarantee each PPS Protection defensive walled in area meets the most noteworthy industry standards.

Main Advantages

High Insulation Performance

Your hardware remains secured with extraordinary electrical cover that viably avoids arcing and breakdown in basic applications.

Superior Chemical Resistance

You can number on exceptional resistance to plasma and different chemical corrosions, guaranteeing long-lasting execution in unforgiving environments.

Dimensional Stability

The moo hygroscopicity of our PPS fabric implies negligible dimensional changes, giving you reliable execution in cleanroom conditions.

Temperature Resistance

Your applications advantage from fabulous high-temperature soundness, keeping up auxiliary astuteness beneath requesting warm conditions.

Flame Retardant Safety

UL94 V-0 certified fire retardancy gives you with the most noteworthy level of security security without trickling or over the top smoke.

Specifications

| Property | Value |

|---|---|

| Material | PPS (Polyphenylene sulfide) |

| Insulation Strength | >20kV/mm |

| Flame Rating | UL94 V-0 |

| Cleanroom Compliance | ISO Class 1 |

| Temperature Range | -40°C to +220°C |

| Certification | ISO9001:2015, RoHS, REACH |

| Customization | OEM/ODM Available |

| Sample Service | Yes |

| Delivery Time | 10-20 Working Days |

Why Choose Us?

15 Years of Industry Experience

Our extensive experience in precision manufacturing ensures you receive products that meet exact specifications and performance requirements.

Advanced R&D Capabilities

With 36% of our staff dedicated to research and 22 patents in our portfolio, you benefit from cutting-edge technology and innovative solutions.

Cost-Effective Solutions

Our China supply chain advantage provides you with 30%-40% cost savings without compromising quality standards.

Comprehensive Quality System

ISO9001:2015 certification and strict quality control processes guarantee reliable product performance for your applications.

Customization Process

Step 1: Consultation

Share your specific requirements and application details with our technical team.

Step 2: Design Development

Our engineers create custom designs based on your specifications and provide technical drawings for approval.

Step 3: Prototyping

We produce samples for your testing and validation before full production begins.

Step 4: Production

Once approved, we manufacture your PPS insulating protective enclosure using our advanced production systems.

Step 5: Quality Control

Each product undergoes rigorous testing to ensure it meets your specifications and industry standards.

Factory Strength

Our state-of-the-art office ranges numerous generation regions with progressed CNC machining centers and accuracy molding gear. You advantage from our incline generation framework that guarantees productive fabricating and reliable quality. Our talented workforce incorporates experts from Singapore's beat ventures, bringing universal ability to each project.

We keep up comprehensive testing research facilities prepared with exactness estimation rebellious, guaranteeing your items meet the strictest quality requirements.

Quality Certification

- ISO9001:2015 Quality Management System

- RoHS Compliance for Environmental Safety

- REACH Regulation Compliance

- UL94 V-0 Flame Retardant Certification

- ISO Class 1 Cleanroom Standards

Transport Packaging

Your items are carefully bundled utilizing anti-static materials and defensive froth to anticipate harm amid transportation. We utilize moisture-proof bundling for worldwide shipping, guaranteeing your PPS Protection defensive walled in area arrives in culminate condition. All bundles incorporate legitimate labeling and documentation for smooth traditions clearance.

FAQ

Q: Does PPS material meet semiconductor cleanroom requirements?

A: Yes, our PPS material meets ISO Class 1 cleanroom requirements and is fully certified for semiconductor clean environments.

Q: What is the typical lead time for custom orders?

A: Standard delivery time is 10-20 working days, depending on order complexity and quantity.

Q: Do you provide technical support for design optimization?

A: Absolutely. Our engineering team offers comprehensive technical consulting to optimize your design for best performance.

Q: Can you handle both small and large volume orders?

A: Yes, we accommodate everything from prototype quantities to high-volume production runs.

Q: What testing do you perform on each product?

A: We conduct dimensional inspection, insulation strength testing, and material property verification for every batch.

Contact Us

Ready to discuss your specific requirements? Our technical team is here to help you find the perfect solution for your application needs.

Email: service@kaihancnc.com

Contact us today for technical consultation, custom quotes, or sample requests. We're committed to providing you with exceptional PPS insulating protective enclosures and service that exceed your expectations.

Learn about our latest products and discounts through SMS or email