- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

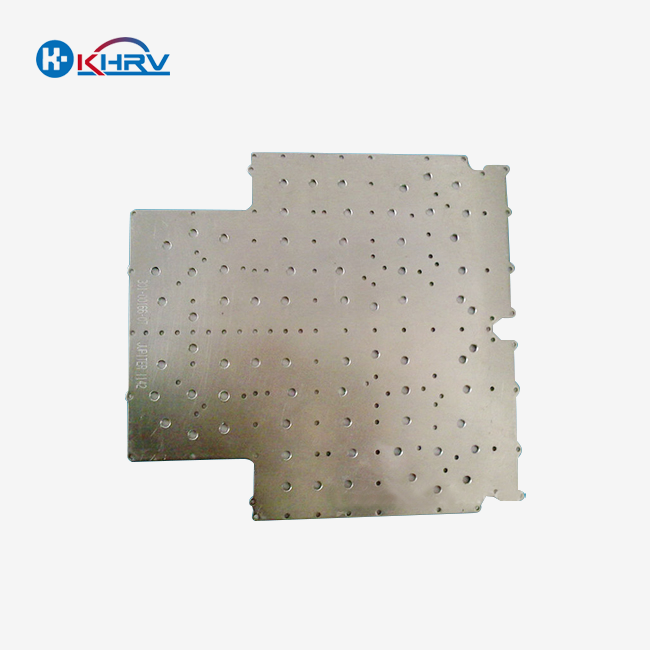

Linear Guide Rails

2. Length: Approx. 617.9mm (as indicated on the drawing)

3. Weight: Approx. 0.8kg

4. Surface Treatment: Clear Anodized (Corrosion-resistant and wear-resistant, matte finish)

5. Hole Configuration: Long, distributed mounting holes (including through holes and positioning holes)

6. Tolerance Standard: Critical dimension tolerance ±0.03mm (e.g., hole center distance), unspecified dimension tolerances according to GB/T1804-m

7. Process Requirements: Surface free of defects, all burrs and flash removed, angle dimensions conform to drawing specifications

8. Environmental Adaptability: Operating temperature -40℃~120℃, suitable for typical industrial workshop conditions

Linear Guide Rails - Precision Aluminum Support Components

Product Introduction

Welcome to Wuxi Kaihan Technology's premium Direct Direct Rails - precision-engineered back components outlined for mechanized gear applications. Our Linear Guide Rails highlight CNC-milled 6061 aluminum combination development with clear anodized surface treatment, giving extraordinary strength and execution for your mechanical mechanization needs. These long strip bolster components are particularly planned to guarantee ideal soundness and exactness in hardware operation.

With over 15 a long time of fabricating ability, we've created these accuracy components to meet the requesting necessities of present day robotization frameworks. Each unit experiences thorough quality control to guarantee dependable execution in mechanical environments.

Main Advantages

Superior Material Performance

Our 6061 aluminum combination development conveys amazing strength-to-weight proportion, guaranteeing negligible hardware stack whereas keeping up basic integrity.

Precision Engineering

Critical measurement resiliences of ±0.03mm ensure culminate arrangement with your hardware mounting focuses, disposing of establishment complications.

Enhanced Durability

Clear anodized surface treatment gives erosion resistance surpassing 500 hours in salt splash testing, idealize for challenging mechanical environments.

Lightweight Design

At around 0.8kg, our Direct Direct Rails won't include pointless weight to your hardware framework.

Temperature Resilience

Operating temperature run of -40℃ to 120℃ guarantees dependable execution over different mechanical conditions.

Specifications

| Parameter | Specification |

|---|---|

| Material | 6061 Aluminum Alloy |

| Length | 617.9mm (Customizable) |

| Weight | Approximately 0.8kg |

| Surface Treatment | Clear Anodized |

| Tolerance | ±0.03mm (Critical dimensions) |

| Operating Temperature | -40℃ to 120℃ |

| Surface Hardness | ≥HV300 |

| Compatible Span | ≤650mm |

| Deformation | ≤0.05mm (600mm span) |

| Corrosion Resistance | >500h Salt Spray Test |

Why Choose Us?

15 Years of Industry Experience

Since 2011, we've been culminating exactness fabricating methods, guaranteeing you get components built with demonstrated expertise.

Cost-Effective Solutions

Our China supply chain advantage offers 30-40% fetched reserve funds without compromising quality standards.

Research-Driven Innovation

With 36% of our group devoted to investigate and advancement, we persistently make strides our Linear Guide Rails technology.

Quality Certifications

ISO9001:2005 certified fabricating forms guarantee steady quality and unwavering quality in each component.

Global Partnerships

Our solid connections with industry pioneers around the world illustrate our commitment to brilliance.

Customization Process

- Initial Consultation - Share your specific requirements and technical drawings

- Design Review - Our engineers analyze your needs and propose optimal solutions

- Prototype Development - We create samples for your testing and approval

- Production Planning - Detailed manufacturing schedule aligned with your timeline

- Quality Verification - Comprehensive testing before shipment

- Delivery & Support - On-time delivery with ongoing technical support

Factory Strength

Our state-of-the-art office in Jiangsu Territory highlights progressed CNC machining centers and exactness testing hardware. With 22 licenses and persistent R&D venture speaking to 8% of yearly income, we keep up cutting-edge fabricating capabilities.

Our incline generation framework empowers effective fabricating whereas keeping up the most elevated quality benchmarks. Proficient group individuals from Singapore's beat ventures bring universal mastery to each project.

Quality Certification

- ISO9001:2005 Quality Administration System

- Comprehensive quality control protocols

- Advanced testing hardware for dimensional accuracy

- Material certification and traceability

- Salt splash erosion testing capabilities

Transport Packaging

Each Straight Direct Rails component is carefully bundled utilizing defensive froth embeds and moisture-resistant materials. Our bundling guarantees secure conveyance whereas anticipating harm amid transportation. Custom bundling arrangements accessible for bulk orders or extraordinary taking care of prerequisites.

FAQ

Q: Can you modify the hole patterns for specific equipment?

A: Yes, we customize hole layouts, quantities, and spacing according to your equipment drawings and mounting requirements.

Q: What's the minimum order quantity?

A: We accommodate both prototype quantities and large-scale production runs, with flexible MOQ based on customization requirements.

Q: How do you ensure dimensional accuracy?

A: Our CNC machining centers and precision measurement equipment guarantee tolerances within ±0.03mm for critical dimensions.

Q: What's the typical lead time?

A: Standard configurations ship within 2-3 weeks, while custom designs typically require 3-4 weeks depending on complexity.

Q: Do you provide technical support after delivery?

A: Absolutely! Our engineering team provides ongoing technical consultation and support throughout your product lifecycle.

Contact Us

Ready to enhance your automation systems with precision Linear Guide Rails? Our expert team is standing by to discuss your specific requirements and provide tailored solutions.

Email: service@kaihancnc.com

Let us help you achieve superior performance and reliability in your automation applications. Contact us today for a detailed consultation and competitive quotation.

Learn about our latest products and discounts through SMS or email