- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Milling Cutter For Stainless Steel

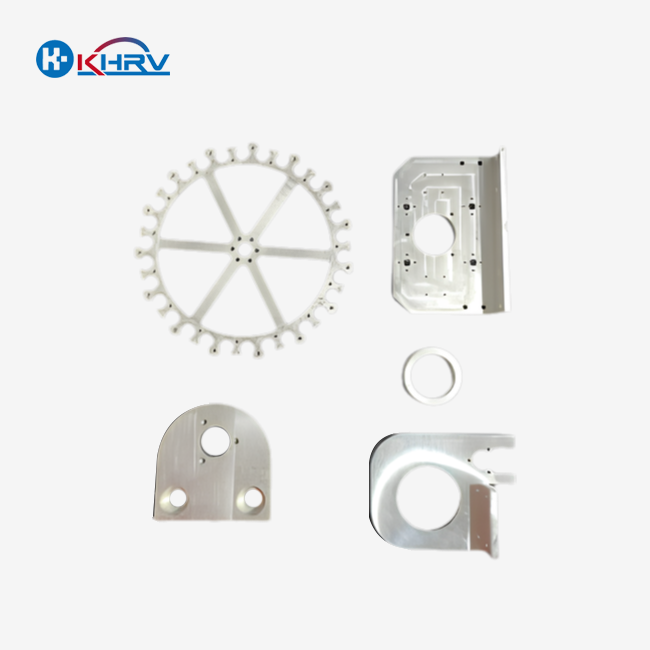

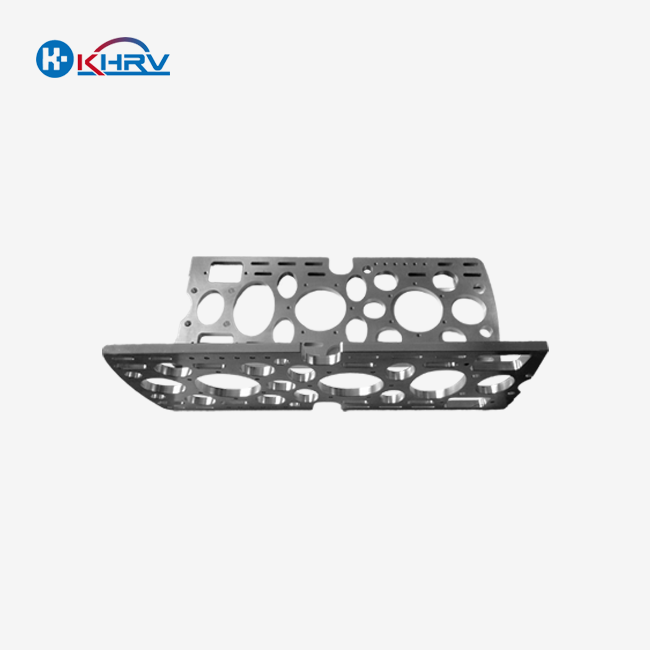

Processing: CNC milling

Applications: Industrial machinery, electronics, medical devices, automotive parts, CNC tools

Services: OEM and ODM customization

Delivery time: 10-20 business days

Certifications: ISO 9001:2015, EU RoHS compliant

Milling Cutter For Stainless Steel: Precision Machining Solutions from Wuxi Kaihan

Welcome to Wuxi Kaihan Technology Co., Ltd., your trusted manufacturer and supplier of high-performance milling cutter for stainless steel. With 15 a long time of ability in exactness machining, we offer cutting-edge arrangements custom-made for the one of a kind challenges of stainless steel preparing. Our processing cutters are outlined to convey uncommon execution, amplified device life, and predominant surface wraps up, making them the perfect choice for businesses requesting accuracy and unwavering quality.

Product Introduction

Our products are engineered to excel in the most demanding applications. Featuring advanced coatings and optimized geometries, these tools ensure efficient chip evacuation, reduced cutting forces, and outstanding heat resistance. Whether you're working on aerospace components, medical devices, or high-precision automotive parts, our milling cutters deliver consistent, high-quality results.

Specifications

|

Feature

|

Description

|

|

Material

|

tungsten steel alloy

|

|

Flute Design

|

variable helix/pitch design

|

|

Cutting Edge

|

reduces vibration and suppresses work hardening

|

|

Diameter Range

|

1mm-20mm

|

|

Length

|

50mm-150mm

|

|

Compatibility

|

Suitable for finishing of stainless steel

|

|

Tolerance

|

diameter4<D≤12,(0-0.02)

12<D≤20,(0-0.03

|

Why Choose Us?

- Expertise: 15 years of experience in precision tool manufacturing

- Innovation: 22 patents and continuous R&D investment

- Quality: Rigorous quality control and ISO certifications

- Support: Comprehensive technical consulting and after-sales service

- Customization: Tailored solutions for your specific machining needs

Customization Process

Our team of experts works closely with you to design and manufacture custom milling cutters that meet your exact specifications and performance requirements.

Factory Strength

At Wuxi Kaihan, we pride ourselves on our state-of-the-art manufacturing facilities and skilled workforce. Our factory boasts advanced CNC machines, precision grinding equipment, and cutting-edge coating technology. With a research team comprising 36% of our staff, we're constantly pushing the boundaries of milling cutter design and performance.

Quality Certification

We hold multiple quality certifications, including ISO 9001:2015 and ISO 14001:2015, ensuring that our milling cutter for stainless steel meet the highest standards of quality and consistency. Our rigorous testing procedures guarantee that every tool leaving our facility performs to your exacting standards.

Transport Packaging

To ensure your milling cutters arrive in perfect condition, we use robust, protective packaging designed specifically for precision tools. Each cutter is individually wrapped and secured in shock-absorbent material, then placed in sturdy boxes for safe transportation.

FAQ

Q: What makes your milling cutters ideal for stainless steel?

A: Our cutters feature specialized coatings and geometries optimized for stainless steel's unique properties, ensuring superior performance and tool life.

Q: Can you provide technical support for implementing your milling cutters?

A: Absolutely! Our team of experts offers comprehensive technical consulting to help you optimize your machining parameters and achieve the best results.

Q: What is the typical lead time for bulk orders of milling cutters?

A: Lead times vary based on order size and specifications, but we generally aim for 2-4 weeks for standard products and 4-6 weeks for custom solutions.

Q: Do you offer sample testing before large purchases?

A: Yes, we provide sample cutters for testing to ensure they meet your performance requirements before committing to a large order.

Q: How do your milling cutters compare to competitors in terms of tool life?

A: Our advanced coatings and optimized designs typically result in tool life improvements of 20-30% compared to standard offerings in the market.

Contact Us

Ready to elevate your stainless steel machining capabilities? Contact our group of specialists nowadays to examine your milling cutter for stainless steel needs and find how Wuxi Kaihan can boost your efficiency. Reach out to us at service@kaihancnc.com for personalized assistance and quotations.

Learn about our latest products and discounts through SMS or email