- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

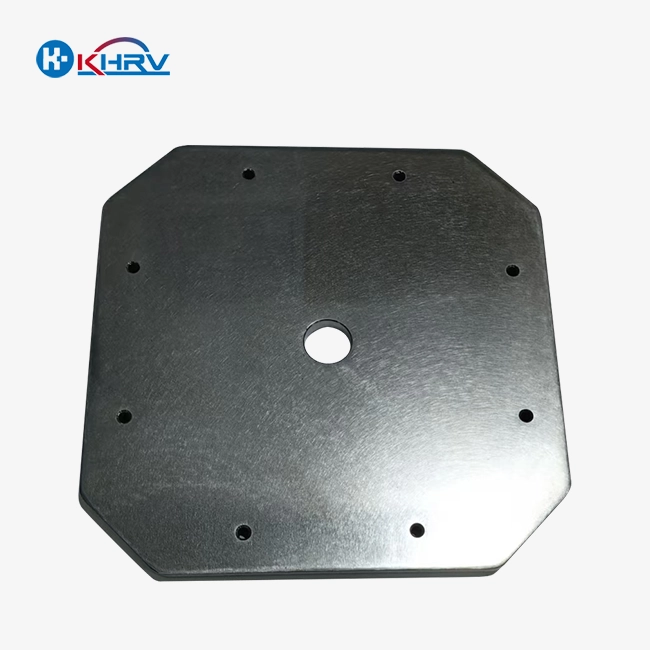

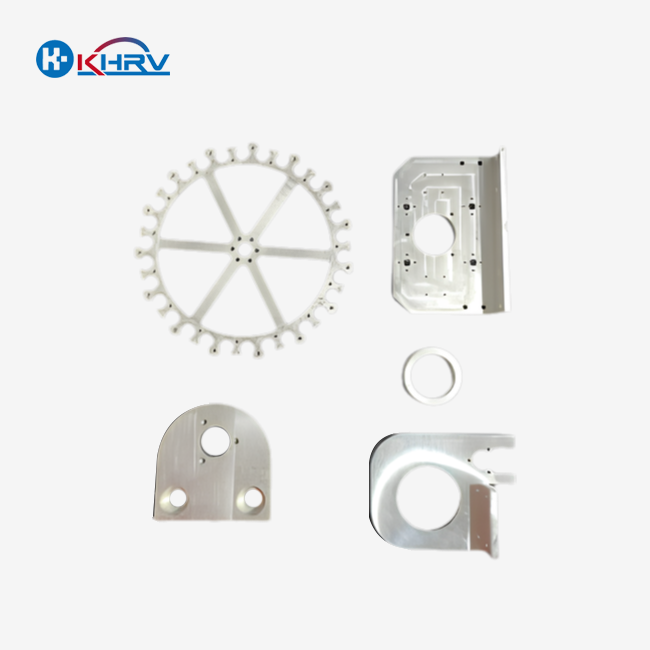

Laser Cutting Precision Parts

Materials: Stainless steel, aluminum alloy, brass, steel, carbide, titanium alloy, etc.

Applications: Industrial machinery, electronics, medical devices, automotive parts, CNC tools.

Services: Sample support, OEM & ODM customization.

Lead Time: 10–20 working days.

Certifications: ISO 9001:2015, EU RoHS compliant.

Laser Cutting Precision Parts: Elevate Your Manufacturing with Wuxi Kaihan

Welcome to Wuxi Kaihan Technology Co., Ltd., your trusted partner for high-quality laser cutting precision parts. With 15 a long time of involvement in the industry, we specialize in conveying remarkable components that meet the demanding guidelines of present day fabricating. Our things are the establishment of improvement over distinctive fragments, tallying car, flying, and therapeutic contraption era. Let's examine how our authority can alter your era line and boost your competitive edge.

Product Introduction

Our things talk to the summit of creating advancement. Utilizing state-of-the-art fiber laser systems, we make components with unparalleled precision and consistency. Whether you're in require of complicated restorative contraption components or incredible car parts, our laser cutting organizations give the precision and immovable quality your wanders ask.

Specifications

| Feature | Description |

|---|---|

| Material Compatibility | Stainless Steel, Aluminum, Titanium, Brass, Copper |

| Thickness Range | 0.1mm to 20mm |

| Tolerance | ±0.1mm or tighter |

| Surface Finish | Ra 0.8-3.2 μm |

| Minimum Hole Diameter | 0.2mm |

| Maximum Sheet Size | 3000mm x 1500mm |

| Turnaround Time | 2-4 weeks (standard), Rush orders available |

Why Choose Us?

- Cutting-Edge Technology: Our advanced fiber laser systems ensure superior edge quality and minimal heat-affected zones.

- Expert Team: With 36% of our staff dedicated to research, we're at the forefront of laser cutting innovation.

- Quality Assurance: ISO 9001 certified processes guarantee consistent, high-quality output.

- Cost-Effective Solutions: Our lean production system translates to competitive pricing without compromising quality.

- Flexibility: We offer both high-volume production and prototype runs to meet diverse client needs.

Customization Process

Our engineers work closely with you to optimize designs for laser cutting, ensuring manufacturability and cost-efficiency.

Factory Strength

At Wuxi Kaihan, we pride ourselves on our comprehensive fabricating capabilities. Our 10,000 square meter office houses cutting-edge laser cutting machines, CNC processing centers, and exactness estimation gear. This coordinates approach permits us to control each viewpoint of generation, from crude fabric choice to last review, guaranteeing the most noteworthy quality items for our clients.

Quality Certification

Our commitment to quality is immovable. We hold ISO 9001:2015 certification, illustrating our adherence to universal quality administration benchmarks. Furthermore, our AS9100 certification for aviation components underscores our capacity to meet the exacting necessities of high-stakes businesses. These certifications, coupled with our thorough in-house quality control forms, ensure that each laser-cut portion meets or surpasses your details.

Transport Packaging

We understand that the journey from our facility to your production line is critical. That's why we've developed robust packaging solutions tailored to protect our laser cutting precision parts during transit. Each component is individually wrapped and secured in custom-designed containers, ensuring they arrive in perfect condition, ready for immediate use in your manufacturing process.

FAQ

Q: What is the lead time for custom products?

A: Standard lead time is 2-4 weeks, but we offer expedited services for urgent orders.

Q: Can you handle small batch production or prototypes?

A: Absolutely! We're equipped to handle orders of all sizes, from single prototypes to large-scale production runs.

Q: How do you ensure the accuracy of laser-cut parts?

A: We employ advanced metrology equipment and follow strict quality control protocols to maintain tolerances as tight as ±0.1mm.

Q: Are your products suitable for medical devices?

A: Yes, we adhere to stringent cleanliness and material traceability standards required for medical device components.

Q: Can you provide DFM (Design for Manufacturing) support?

A: Certainly! Our engineering team offers comprehensive DFM feedback to optimize your designs for laser cutting.

Contact Us

Ready to elevate your manufacturing with our laser cutting precision parts? Contact our expert team at service@kaihancnc.com for personalized support and quotations. Let's bring your precision manufacturing vision to life together.

Learn about our latest products and discounts through SMS or email