- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

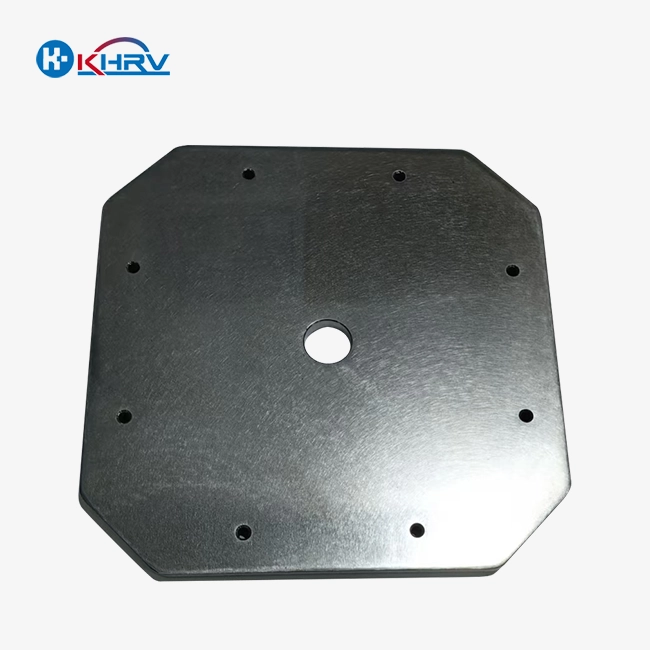

7075 Aircraft Aluminum Base

Surface Treatment: Hard anodizing (thickness: ≥50μm)

Surface Hardness: ≥HV500 (far higher than ordinary anodizing)

Precision Tolerance: Flatness ≤0.08mm/100mm

Characteristics: Ultra-high strength, ultra-hard and wear-resistant, lightweight

Support sample service

Support OEM,ODM customization

Delivery time: 10-20 working days

Certification: ISO9001:2015 , Complies with EU RoHS standards

7075 Aircraft Aluminum Base - Ultra-High Strength Precision Platform

Product Introduction

When you require uncommon quality and unwavering quality for your accuracy gear, our 7075 aircraft aluminum base conveys aerospace-grade execution. Made from premium 7075-T651 flying aluminum with difficult anodizing treatment, this base gives unmatched solidness for requesting applications. Whether you're building rambles, mechanical technology frameworks, or high-precision rebellious, our 7075 Airplane Aluminum Base offers the culminate establishment for your basic ventures. With over 15 a long time of fabricating skill, we've built this base to surpass industry guidelines whereas keeping up cost-effectiveness.

Main Advantages

Aerospace-Grade Strength Performance

Our bases include ductile quality distant surpassing standard 6061 aluminum, conveying steel-like toughness at altogether lighter weight. This extraordinary strength-to-weight proportion makes them perfect for applications where each gram matters.

Superior Surface Protection

Hard anodizing treatment makes a defensive layer with ≥HV500 surface hardness. This armor-grade security gives exceptional wear resistance and erosion assurance, amplifying benefit life by over 500% compared to standard aluminum components.

Precision Engineering Excellence

Manufactured to aviation resiliences with levelness ≤0.08mm/100mm, guaranteeing reliable execution over all working conditions. Our progressed CNC machining capabilities ensure dimensional precision that meets the most requesting specifications.

Temperature Stability Assurance

Maintains structural integrity and precision across extreme temperature ranges from -50℃ to 120℃, with minimal dimensional variation ensuring reliable performance in harsh environments.

Specifications

| Parameter | Specification |

|---|---|

| Material | 7075-T651 Aviation Aluminum |

| Surface Treatment | Hard Anodizing (≥50μm thickness) |

| Surface Hardness | ≥HV500 |

| Precision Tolerance | Flatness ≤0.08mm/100mm |

| Tensile Strength | ≥572MPa |

| Temperature Range | -50℃ to 120℃ |

| Weight Advantage | 40% lighter than steel equivalents |

| Delivery Time | 10-20 working days |

| Customization | OEM/ODM available |

| Sample Service | Available |

Why Choose Us?

Proven Manufacturing Excellence

With 15 a long time of exactness fabricating involvement and 22 licenses, we bring unmatched skill to each extend. Our group incorporates experts from Singapore's driving ventures, guaranteeing world-class quality standards.

Cost-Effective Solutions

Leveraging China's supply chain preferences, we provide 30%-40% taken a toll investment funds without compromising quality. Our incline generation framework maximizes proficiency whereas keeping up strict quality control.

Comprehensive Quality Systems

ISO9001:2015 certification and EU RoHS compliance ensure reliable quality. Our thorough testing conventions guarantee each base meets aviation industry standards.

Advanced Production Capabilities

State-of-the-art CNC hardware and exactness testing rebellious empower us to handle complex geometries and tight resistances with uncommon repeatability.

Customization Process

Step 1: Requirements Analysis

Share your specifications, drawings, or samples. Our engineering team will analyze your requirements and propose optimal solutions.

Step 2: Design Optimization

We'll create detailed technical drawings and recommend improvements for manufacturability and performance enhancement.

Step 3: Prototype Development

Rapid prototyping service allows you to validate design before full production, ensuring perfect fit and function.

Step 4: Production & Quality Control

Full-scale manufacturing with continuous quality monitoring and final inspection to guarantee specification compliance.

Factory Strength

Our advanced office ranges different generation lines with progressed CNC machining centers, mechanized surface treatment frameworks, and comprehensive testing research facilities. Investigate work force include 36% of our workforce, with 8% yearly income contributed in R&D development.

Strategic associations with worldwide industry pioneers approve our fabricating capabilities and quality measures. Our incline generation framework guarantees effective workflow from crude materials to wrapped up products.

Quality Certification

- ISO9001:2015 Quality Management System

- EU RoHS Compliance Certification

- Comprehensive Material Traceability

- Advanced Testing Laboratory Validation

Every 7075 aircraft aluminum base undergoes rigorous testing including dimensional verification, surface hardness testing, and material composition analysis to ensure consistent quality.

Transport Packaging

Professional packaging protects your precision components during shipment. We use:

- Custom foam inserts for impact protection

- Anti-static materials for electronic compatibility

- Moisture barrier packaging for long-term storage

- Clear labeling and documentation for easy identification

FAQ

Q: What makes hard anodizing superior to standard treatments?

A: Hard anodizing creates a ≥50μm protective layer with ≥HV500 hardness, providing over 5 times the wear resistance of standard aluminum treatments.

Q: Can these bases handle high-frequency vibrations?

A: Yes, 7075 aluminum's excellent fatigue resistance combined with optimized design geometry ensures reliable performance under continuous vibration exposure.

Q: What's the typical lead time for custom sizes?

A: Standard customizations require 10-20 working days. Complex geometries may need additional time for tooling preparation.

Q: Do you provide material certifications?

A: Absolutely. We provide complete material traceability documentation including chemical composition analysis and mechanical property verification.

Contact Us

Ready to enhance your project with premium 7075 aircraft aluminum base solutions? Our technical team stands ready to discuss your specific requirements and provide expert recommendations.

Email: service@kaihancnc.com

Contact us today for detailed quotations, technical specifications, or sample requests. We're committed to delivering precision solutions that exceed your expectations while providing exceptional value through our comprehensive manufacturing capabilities.

Learn about our latest products and discounts through SMS or email