- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Stainless steel indexing plate

Indexing accuracy: ± 30 arcseconds (Arc-sec)

Main bore diameter tolerance: H7

Index hole position accuracy: ± 0.015 mm

Surface treatment: Passivation

Key characteristics: High rigidity, high wear resistance, rust prevention

Support sample service

Support OEM,ODM customization

Delivery time: 10-20 working days

Certification: ISO9001:2015 , Complies with EU RoHS standards

High-Precision Stainless Steel Indexing Plate - Professional CNC Machining Solutions

Product Introduction

Looking for dependable accuracy situating in your CNC operations? Our stainless steel indexing plate conveys remarkable precision and toughness for requesting machining applications. Fabricated from premium 304/316 stainless steel, this precision-engineered component guarantees reliable precise situating with ±30 arcsecond precision. Whether you're working with FANUC, Siemens, Haas, or Makino machining centers, our ordering plates give the unwavering quality you require for basic fabricating processes.

This center component serves as an basic apparatus for CNC machine administrators who request accuracy precise ordering. The high-precision ordering gap framework ensures repeatability and soundness amid complex machining operations, making it idealize for aviation, car, and therapeutic gadget manufacturing.

Main Advantages

Superior Fabric Quality: Made from premium 304/316 stainless steel for exceptional erosion resistance and life span in challenging mechanical environments.

Exceptional Accuracy: Accomplish ±30 arcsecond ordering exactness with ±0.015mm file gap position resistance, guaranteeing reliable comes about over all operations.

High Inflexibility Plan: Non-deformable development keeps up dimensional soundness beneath overwhelming loads and warm cycling conditions.

Precision Ground Surface: Progressed pounding forms provide predominant surface wrap up and dimensional precision for ideal performance.

Versatile Compatibility: Works consistently with standard CNC machining centers and can be customized for particular gear interfaces.

Comprehensive Customization: Full back for custom gap designs, distances across, and ordering points to meet your one of a kind tooling requirements.

Specifications

| Parameter | Specification |

|---|---|

| Material | 304/316 Stainless Steel |

| Indexing Accuracy | ±30 Arcseconds |

| Main Bore Tolerance | H7 |

| Index Hole Position Accuracy | ±0.015 mm |

| Surface Treatment | Passivation |

| Minimum Hole Diameter | φ0.5mm (±0.005mm tolerance) |

| Key Features | High rigidity, wear resistance, corrosion prevention |

| Compliance | EU RoHS Standards |

| Delivery Time | 10-20 Working Days |

Why Choose Us?

15 Years of Manufacturing Excellence: Since 2011, we've built a reputation for delivering precision components that exceed industry standards.

Cost-Effective Solutions: Benefit from China's supply chain advantages with 30%-40% cost savings without compromising quality.

Advanced R&D Capabilities: Our team includes professionals from Singapore's leading enterprises, with 36% research personnel and 8% annual revenue invested in R&D.

Proven Innovation: Backed by 22 patents and extensive industry experience in precision manufacturing.

Quality Assurance: ISO9001:2015 certified manufacturing processes ensure consistent stainless steel indexing plate reliability.

Customization Process

Step 1: Share your technical drawings or specifications with our engineering team for detailed review.

Step 2: Receive comprehensive design consultation and optimization recommendations within 24 hours.

Step 3: Approve the customized design proposal including materials, tolerances, and delivery timeline.

Step 4: Production begins using advanced CNC equipment and precision testing instruments.

Step 5: Rigorous quality inspection and documentation before secure packaging and shipment.

Factory Strength

Our state-of-the-art office in Jiangsu Area combines progressed fabricating hardware with exactness testing rebellious. We keep up a comprehensive incline generation framework that empowers solid associations with worldwide industry pioneers. Our talented workforce and set up quality administration frameworks guarantee each stainless steel ordering plate meets rigid execution standards.

Quality Certification

We keep up ISO9001:2015 Quality Administration Framework certification and comply with EU RoHS measures. Through strict quality control forms and different certification frameworks, we guarantee dependable item execution that meets universal standards.

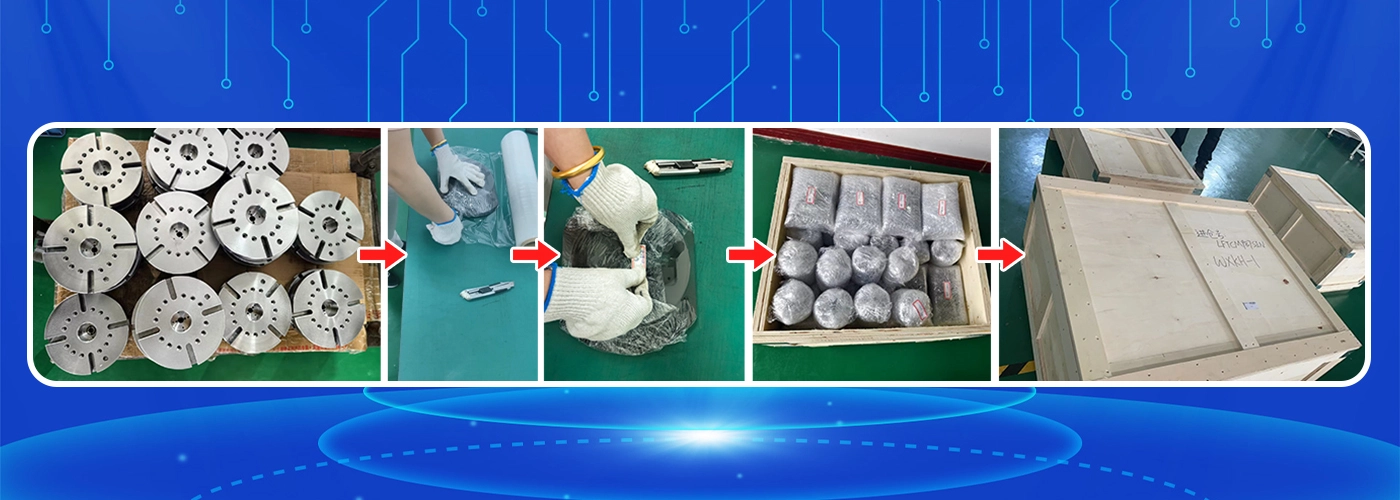

Transport Packaging

Each ordering plate gets cautious defensive bundling to anticipate harm amid shipping. We utilize anti-corrosion materials and secure padding frameworks to keep up item judgment from our plant to your office.

FAQ

Q: Which machining center brands are compatible?

A: Our plates work with FANUC, Siemens, Haas, Makino, and other mainstream brands. Custom interfaces available for specific equipment.

Q: Can hole patterns be customized?

A: Yes, we offer complete customization for hole quantity, diameter, and indexing angles according to your tooling requirements.

Q: What's the minimum order quantity?

A: We support sample orders and small batch production to meet diverse customer needs.

Q: How do you ensure accuracy standards?

A: Every product undergoes precision measurement using advanced testing equipment before shipment.

Contact Us

Ready to enhance your CNC machining precision? Our technical team is standing by to discuss your stainless steel indexing plate requirements. Contact us at service@kaihancnc.com for detailed quotations, technical specifications, or custom design consultation. Experience the reliability and precision that industry leaders trust for their critical manufacturing operations.

Learn about our latest products and discounts through SMS or email