- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

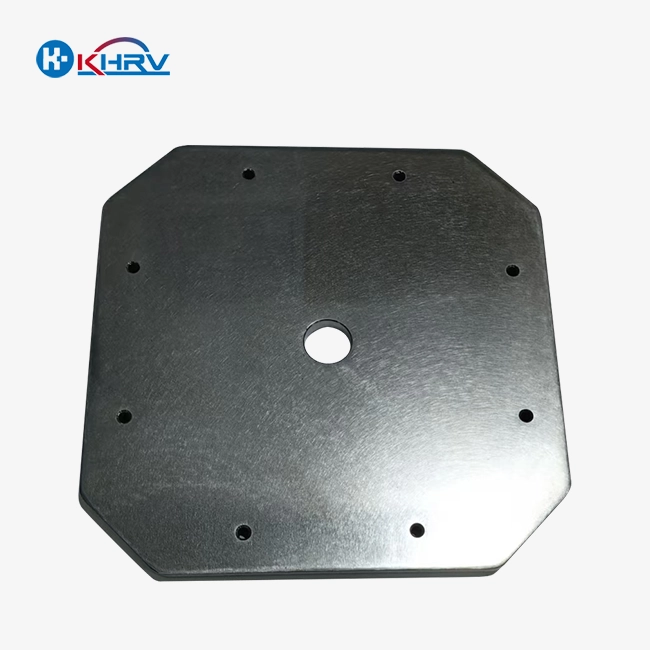

Auto Industrial CNC Milling Parts

Processing Methods: CNC Milling, EDM, Surface Hard Anodizing, Galvanizing, Chrome Plating, etc.

Applications: Auto Parts

Services: Sample Support, OEM & ODM Customization

Lead Time: 10–20 Working Days

Certification: ISO 9001:2015 Certified, Compliant with EU RoHS Standards

Auto Industrial CNC Milling Parts - Precision Engineered for Automotive Excellence | Wuxi Kaihan Technology Co., Ltd.

Wuxi Kaihan Technology Co., Ltd. is a leading manufacturer and supplier of Auto Industrial CNC Milling Parts. With 15 years of experience in precision engineering, we specialize in producing high-quality components for the automotive industry. Our advanced CNC milling capabilities and expertise in materials like aluminum alloys and steel make us the ideal partner for automotive OEMs and Tier 1 suppliers. We pride ourselves on delivering products that meet the stringent quality standards and tight tolerances required in modern vehicle production.

Product Introduction

Our products are designed to meet the demanding needs of the automotive industry. We utilize state-of-the-art CNC milling technology to produce components with exceptional precision and consistency. Our parts are engineered to enhance vehicle performance, durability, and efficiency across various automotive applications.

Specifications

| Feature | Description |

|---|---|

| Materials | Aluminum alloys, Steel, Titanium |

| Tolerance | ±0.01mm |

| Surface Finish | Ra 0.4-3.2 |

| Production Capacity | Up to 10,000 units/month |

| Certifications | IATF 16949, ISO 9001 |

| Lead Time | 4-8 weeks (standard) |

| Minimum Order Quantity | 100 pieces |

Why Choose Us?

- Automotive Industry Expertise: 15 years of experience in precision manufacturing for the automotive sector.

- Advanced Technology: Utilization of 5-axis CNC machining and high-speed milling for complex geometries.

- Quality Assurance: Rigorous quality control processes and certifications to meet automotive standards.

- Flexible Production: Capability to handle both high-volume orders and specialized, low-volume runs.

- Material Expertise: Proficiency in working with a wide range of automotive-grade materials.

- Cost-Effective Solutions: Competitive pricing without compromising on quality or performance.

Customization Process

We offer tailored solutions to meet your specific products requirements, from design optimization to prototype development and full-scale production.

Factory Strength

Our state-of-the-art facility is equipped with advanced CNC milling centers, CMM inspection equipment, and a lean production system. Our team of skilled engineers and technicians, many with experience from top Singaporean enterprises, ensures the highest quality in every component we produce. With 36% of our staff dedicated to research and development, we continuously innovate to meet the evolving needs of the automotive industry.

Quality Certification

We maintain strict quality control measures throughout our production process. Our IATF 16949 and ISO 9001 certifications demonstrate our commitment to meeting the rigorous standards of the automotive industry. Each Auto Industrial CNC Milling Part undergoes thorough inspection to ensure it meets specified tolerances and performance criteria.

Transport Packaging

We use industry-standard packaging methods to ensure the safe transport of your Auto Industrial CNC Milling Parts. Our packaging is designed to protect against damage during shipping and includes:

- Custom-designed foam inserts

- Anti-static bags for sensitive components

- Sturdy, reinforced cartons

- Palletization for bulk orders

FAQ

Q: What is the typical lead time for the products?

A: Our standard lead time is 4-8 weeks, depending on the complexity and volume of the order. We can accommodate rush orders for urgent needs.

Q: Can you provide prototypes before full production?

A: Yes, we offer prototyping services to ensure the design meets your specifications before proceeding with full-scale production.

Q: Do you offer any value-added services for the products?

A: We provide additional services such as heat treatment, surface finishing, and assembly to deliver complete solutions.

Q: How do you ensure the quality of your products?

A: We employ a multi-step quality control process, including in-process inspections and final CMM verification, to ensure each part meets the required specifications.

Q: Can you handle large volume orders for the products?

A: Absolutely. Our production capacity allows us to fulfill high-volume orders while maintaining consistent quality and timely delivery.

Contact Us

Ready to elevate your automotive components with our precision Auto Industrial CNC Milling Parts? Contact our expert team today to discuss your project requirements and receive a customized quote. Reach out to us at service@kaihancnc.com for prompt assistance.

Learn about our latest products and discounts through SMS or email