- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

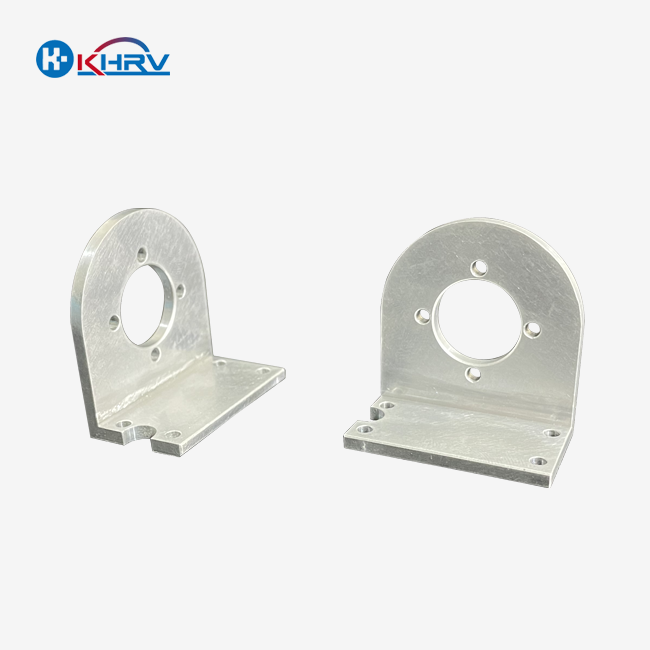

Lifting Platform Mounting Plate

Flatness: ≤ 0.08mm/1000mm

Treatment: Hard anodizing

Load: Static load ≥ 1500kg

Characteristics: High rigidity, lightweight, fatigue resistant

Support sample service

Support OEM,ODM customization

Delivery time: 10-20 working days

Certification: ISO9001:2015 , Complies with EU RoHS standards

Lifting Platform Mounting Plate - Precision Aviation Aluminum Base

Are you looking for a solid establishment for your robotized lifting frameworks? Our lifting platform mounting plate conveys extraordinary execution with 7075-T651 flying aluminum development. This precision-engineered mounting plate guarantees smooth Z-axis movement in computerized generation lines. With prevalent levelness resilience of ≤0.08mm/1000mm and inactive stack capacity surpassing 1500kg, it gives the steadiness your gear requests. The difficult anodized surface treatment ensures long-lasting toughness in requesting mechanical environments.

Main Advantages

Smooth and Stable Operation

High levelness necessities guarantee smooth, unhindered development all through your lifting applications. Your gear works with negligible vibration and greatest precision.

Robust Structure Design

Our mounting plates highlight tall load-bearing capacity and remarkable twisting resistance. The strengthened structure withstands requesting mechanical conditions whereas keeping up dimensional accuracy.

Rational Engineering

Pre-drilled standard mounting gaps disentangle integration with your existing frameworks. You spare profitable establishment time whereas guaranteeing appropriate component alignment.

Premium Material Selection

7075-T651 flying aluminum gives the idealize adjust of quality, weight, and erosion resistance. This aerospace-grade fabric guarantees solid execution in challenging environments.

Specifications

| Parameter | Value |

|---|---|

| Material | 7075-T651 Aviation Aluminum |

| Flatness | ≤ 0.08mm/1000mm |

| Surface Treatment | Hard Anodizing |

| Static Load Capacity | ≥ 1500kg |

| Dynamic Load (10Hz) | ≥ 500kg |

| Surface Hardness | HV≥400 |

| Weight | Lightweight Design |

| Characteristics | High Rigidity, Fatigue Resistant |

| Delivery Time | 10-20 Working Days |

| Certification | ISO9001:2015, EU RoHS Compliant |

Why Choose Us?

15 Years of Industry Experience

Since 2011, we have specialized in exactness fabricating. Our group incorporates experts from Singapore's best endeavors, guaranteeing world-class quality standards.

Strong R&D Foundation

With 36% investigate work force and 8% yearly R&D venture, we hold 22 licenses. This skill deciphers into prevalent item execution for your applications.

Cost-Effective Solutions

Our China supply chain advantage conveys 30%-40% fetched reserve funds without compromising quality. You get premium items at competitive prices.

Quality Assurance

ISO9001:2015 certification and strict quality control guarantee each Lifting Stage Mounting Plate meets demanding standards.

Customization Process

Step 1: Requirements Analysis

Share your specific application requirements, load conditions, and dimensional needs with our engineering team.

Step 2: Design Optimization

Our experts create customized solutions matching your exact specifications and performance requirements.

Step 3: Sample Production

We provide sample services for testing and validation before full production begins.

Step 4: Quality Verification

Rigorous testing ensures your custom mounting plate meets all performance criteria.

Step 5: Production and Delivery

Lean manufacturing processes deliver your order within 10-20 working days.

Factory Strength

Our comprehensive office combines progressed CNC gear with exactness testing disobedient. The incline generation framework guarantees reliable quality from plan to conveyance. Solid associations with worldwide industry pioneers approve our fabricating capabilities.

Research staff include 36% of our workforce, driving nonstop development. This specialized mastery empowers us to unravel complex designing challenges productively.

Quality Certification

- ISO9001:2015 Quality Management System

- EU RoHS Standards Compliance

- Strict Quality Control Protocols

- Advanced Testing Equipment Verification

These certifications ensure every product meets international quality standards. Your lifting platform mounting plate undergoes comprehensive testing before shipment.

Transport Packaging

Professional packaging protects your mounting plates during transit. We use shock-resistant materials and proper securing methods. Each package includes detailed inspection reports and handling instructions.

International shipping options accommodate global delivery requirements. Tracking information keeps you informed throughout the process.

FAQ

Q: What makes your mounting plates suitable for high-frequency applications?

A: Our dynamic load rating of ≥500kg at 10Hz frequency, combined with fatigue-resistant 7075-T651 aluminum, ensures reliable performance in demanding applications.

Q: Can you customize mounting hole patterns?

A: Yes, we provide OEM/ODM customization for mounting configurations, dimensions, and surface treatments based on your requirements.

Q: How does hard anodizing improve performance?

A: Hard anodizing creates a surface hardness of HV≥400, providing wear resistance life 5 times greater than standard aluminum treatments.

Q: What quality control measures ensure consistency?

A: We employ strict quality control protocols, precision testing instruments, and ISO9001:2015 certified processes for consistent quality.

Contact Us

Ready to enhance your lifting system performance? Our technical team stands ready to discuss your lifting platform mounting plate requirements. Whether you need standard configurations or custom solutions, we provide comprehensive support from initial consultation through after-sales service.

Contact our experts today at service@kaihancnc.com for technical consultation and quotations. Experience the reliability and precision that industry leaders trust for their critical applications.

Learn about our latest products and discounts through SMS or email