- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Rotary Table Accessories

2. Weight: 0.944kg

3. Core structure/dimensions: Ring structure (outer diameter φ100mm, inner diameter φ80mm, thickness 10mm), 4 sets of Φ10 through holes (hole center distance φ90mm)

4. Process requirements: CNC milling, full deburring, sharp edges chamfered C0.5/R0.5

5. Accuracy standards: Dimensional tolerances (critical positioning dimension φ87.60⁰₋₀.₀₅mm); Geometric tolerances (roundness ≤0.05mm, coaxiality ≤0.04mm)

6. Compatible equipment: Industrial-grade 4-axis CNC rotary table (PKMS180 series)

7. Core function: The Rotary Table is connected and positioned to the base, ensuring the coaxiality of the Rotary Table's rotation.

Rotary Table Accessories - Premium Quality Components for Precision Machining

Product Introduction

Looking for dependable revolving table adornments that provide extraordinary exactness and execution? Our rotary table accessories are built to meet the requesting necessities of mechanical CNC applications. These fundamental components serve as the basic association and situating components between your rotational table and base framework, guaranteeing ideal coaxiality and rotational precision. Fabricated with 40Cr combination auxiliary steel and accuracy CNC processing forms, these adornments ensure prevalent toughness and steady execution for your machining operations.

Our extras include a vigorous ring structure plan with an external distance across of φ100mm and inward distance across of φ80mm. Each component experiences strict quality control to meet dimensional resiliences and geometric accuracy guidelines that mechanical applications demand.

Main Advantages

Precise Positioning Technology

- Roundness exactness ≤0.05mm guarantees culminate coaxiality

- Critical situating measurement φ87.60⁰₋₀.₀₅mm tolerance

- Coaxiality ≤0.04mm between rotating table and base

Superior Material Construction

- 40Cr combination basic steel for greatest durability

- Precision processing surface treatment (Ra≤1.6μm)

- High shear quality anticipating component loosening

Efficient Installation System

- 4 sets of Φ10 through gaps with φ90mm center distance

- Precise gap arrangement dispenses with rehashed adjustments

- Full deburring with C0.5/R0.5 chamfered edges

Excellent Compatibility

- Perfectly matches PKMS180 arrangement revolving tables

- Custom gap formats accessible for diverse brands

- Flexible thickness choices from 8-15mm

Specifications

| Parameter | Specification |

|---|---|

| Material | 40Cr Alloy Structural Steel |

| Weight | 0.944kg |

| Outer Diameter | φ100mm |

| Inner Diameter | φ80mm |

| Thickness | 10mm (8-15mm customizable) |

| Through Holes | 4 sets of Φ10 |

| Hole Center Distance | φ90mm |

| Surface Roughness | Ra≤1.6μm |

| Roundness Tolerance | ≤0.05mm |

| Coaxiality Tolerance | ≤0.04mm |

| Compatible Equipment | Industrial 4-axis CNC Rotary Tables |

Why Choose Us?

15 Years of Manufacturing Excellence

Since 2011, we have specialized in accuracy instrument parts fabricating. Our group incorporates 36% investigate faculty with mastery from Singapore's beat enterprises.

Cost-Effective Solutions

Benefit from China's supply chain preferences with 30%-40% taken a toll investment funds whereas keeping up worldwide quality standards.

Advanced Production Capabilities

Our CNC processing and turning offices utilize state-of-the-art gear with accuracy testing disobedient all through the generation prepare.

Quality Assurance

ISO9001:2005 certified quality management system ensures consistent product performance and reliability.

Customization Process

- Requirement Analysis - Share your specific application needs and equipment compatibility requirements

- Technical Design - Our engineering team develops customized solutions based on your specifications

- Sample Production - Prototype manufacturing with precision testing and validation

- Quality Approval - Comprehensive inspection and customer approval process

- Mass Production - Efficient manufacturing with strict quality control standards

- Delivery & Support - Reliable packaging and comprehensive after-sales service

Factory Strength

Found in Jiangsu Area, our 15-year set up office combines progressed fabricating innovation with incline generation frameworks. We keep up solid organizations with worldwide industry pioneers through our demonstrated track record of quality and reliability.

Our inquire about and improvement venture speaks to 8% of yearly income, upheld by 22 licenses that illustrate our commitment to development and specialized excellence.

Quality Certification

Our comprehensive quality administration framework incorporates ISO9001:2005 certification. Each rotary table accessories component experiences thorough testing to guarantee dimensional exactness, fabric astuteness, and execution unwavering quality some time recently shipment.

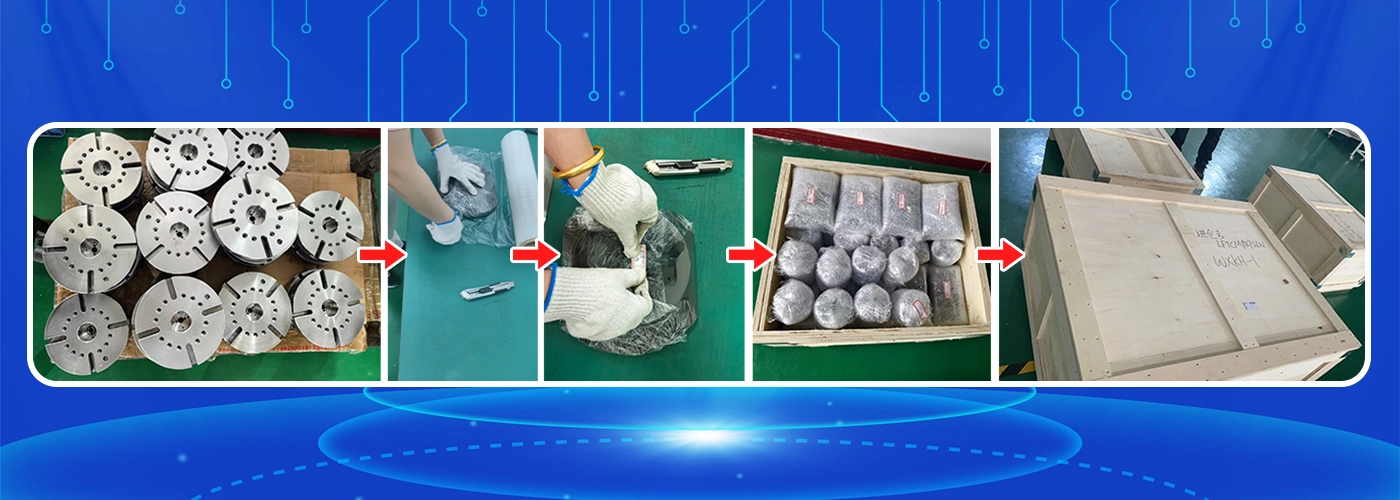

Transport Packaging

We utilize defensive bundling outlined particularly for accuracy components. Each embellishment is carefully secured to avoid harm amid transportation whereas keeping up cleanliness guidelines required for CNC applications.

FAQ

Q: Are these accessories compatible with rotary tables from other manufacturers?

A: Yes, we can customize hole layouts and dimensions to match various rotary table interface specifications beyond the standard PKMS180 series.

Q: Can the thickness be adjusted for specific applications?

A: Absolutely. We support customized thicknesses ranging from 8-15mm while maintaining the same precision standards.

Q: What is the typical lead time for custom orders?

A: Standard customization typically requires 2-3 weeks depending on specifications and quantity requirements.

Q: Do you provide technical support for installation?

A: Yes, we offer comprehensive technical consulting support to ensure proper installation and optimal performance.

Contact Us

Ready to enhance your CNC operations with premium rotary table accessories ? Our technical team is ready to discuss your specific requirements and provide customized solutions.

Email: service@kaihancnc.com

Contact us today for detailed specifications, custom quotes, or technical consultation. We're committed to delivering precision components that exceed your performance expectations.

Learn about our latest products and discounts through SMS or email