- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

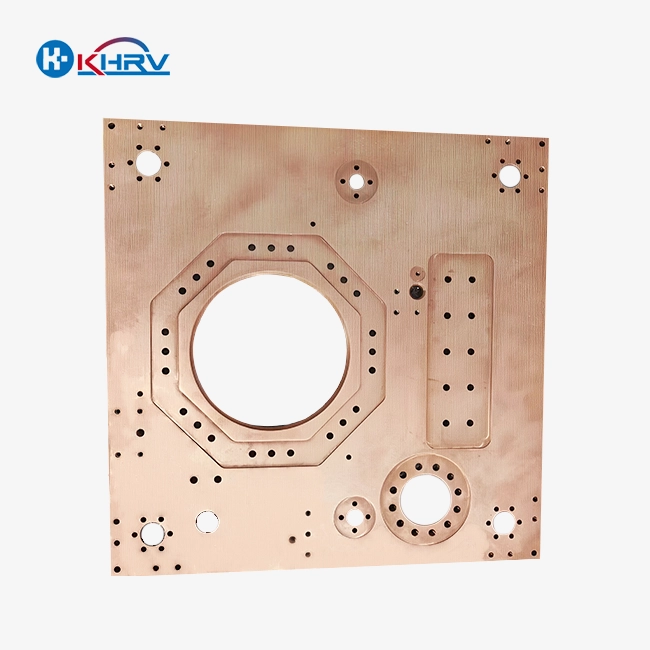

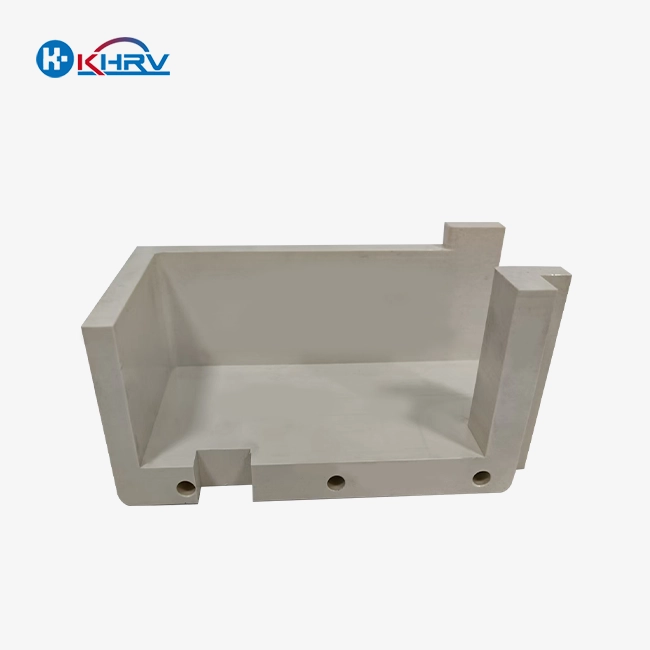

Precision Ball End Mill

Processing: CNC milling

Applications: Industrial machinery, electronics, medical devices, automotive parts, CNC tools

Services: OEM and ODM customization

Delivery time: 10-20 business days

Certifications: ISO 9001:2015, EU RoHS compliant

Precision Ball End Mills: Elevate Your Machining Precision

Wuxi Kaihan Technology Co., Ltd. is a leading manufacturer and supplier of high-quality Precision Ball End Mills. With 15 a long time of encounter in R&D and fabricating, we offer predominant items that convey unmatched execution and precision. Our progressed generation offices, talented group, and commitment to development guarantee that our items meet the most noteworthy industry guidelines, making us the favored choice for accuracy machining needs over different segments.

Product Introduction

Our products are designed to excel in complex 3D contouring, mold making, and precision finishing operations. Engineered with premium carbide and advanced coatings, these tools offer exceptional wear resistance, thermal stability, and cutting efficiency.

Specifications

|

Feature

|

Description

|

|

Material

|

tungsten steel alloy

|

|

Flute Design

|

Spherical cutting head

|

|

Cutting Edge

|

High-precision ball radius ensures excellent surface finish and accuracy

|

|

Diameter Range

|

1mm-20mm

|

|

Length

|

50mm-150mm

|

|

Compatibility

|

Suitable for machining alloy steel and die steel with hardness ranging from HRC 45 to HRC 68.

|

|

Tolerance

|

diameter4<D≤12,(0-0.02)

12<D≤20,(0-0.03)

|

Why Choose Us?

- Superior Quality: Rigorous quality control ensures consistent performance and longevity.

- Advanced Technology: State-of-the-art CNC grinding for precise geometry and superior surface finish.

- Customization: Tailored solutions to meet specific machining requirements.

- Technical Support: Expert guidance on tool selection and optimization for your applications.

- Competitive Pricing: Excellent value without compromising on quality.

Customization Process

Our team works closely with you to design and manufacture Precision Ball End Mills tailored to your unique specifications and applications.

Factory Strength

At Wuxi Kaihan, we pride ourselves on our cutting-edge manufacturing facilities. Our 10,000 square meter plant houses advanced CNC grinding machines, automated inspection systems, and a dedicated R&D center. This infrastructure allows us to maintain strict quality control and drive continuous innovation in our production.

Quality Certification

Our commitment to quality is evidenced by our ISO 9001:2015 certification. Additionally, we adhere to industry-specific standards such as AS9100D for aerospace applications. Each product undergoes rigorous testing, including dimensional accuracy checks and material composition analysis, ensuring that every tool meets our exacting standards.

Transport Packaging

We understand the importance of protecting your investment. Our products are carefully packaged in custom-designed, shock-resistant cases. For bulk orders, we use reinforced cartons with foam inserts to prevent damage during transit, ensuring your tools arrive in perfect condition, ready for immediate use.

FAQ

Q1: What materials can your products machine?

A1: Our instruments are outlined for a wide run of materials, counting solidified steels, titanium combinations, aluminum, and composites.

Q2: How long do your products typically last?

A2: Tool life varies based on application, but our customers report 20-30% longer life compared to standard tools due to our advanced coatings and geometries.

Q3: Do you offer rush orders for urgent projects?

A3: Yes, we offer expedited production and shipping for time-sensitive orders. Please contact our sales team for details.

Q4: Can I get samples before placing a bulk order?

A4: Absolutely. We provide sample products for testing and evaluation to ensure they meet your specific requirements.

Q5: What support do you offer for tool implementation?

A5: Our technical team provides comprehensive support, including cutting parameter recommendations and on-site optimization assistance if needed.

Contact Us

Ready to elevate your machining precision? Contact our expert team today to discuss your Precision Ball End Mill needs. We're committed to finding the idealize arrangement for your application. E-mail us at service@kaihancnc.com for provoke help and personalized benefit.

Learn about our latest products and discounts through SMS or email