- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

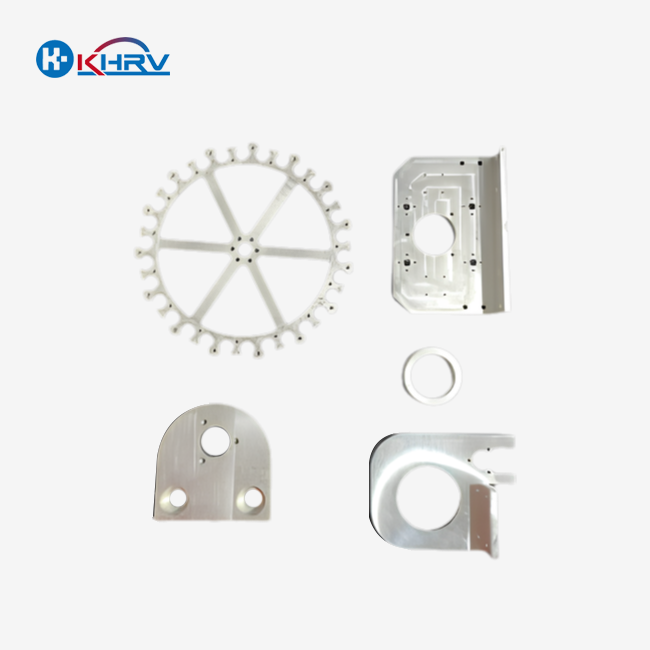

Aluminum Motor Mounting Plate

Material: 6061-T6 Aluminum Alloy

Flatness: ≤ 0.05 mm

Treatment: Black Anodized

Features: High rigidity, lightweight, easy installation

Support sample service

Support OEM,ODM customization

Delivery time: 10-20 working days

Certification: ISO9001:2015 , Complies with EU RoHS standards

Aluminum Motor Mounting Plate - Precision Engineering for Superior Performance

Looking for a solid mounting arrangement for your mechanical applications? Our aluminum motor mounting plate conveys remarkable exactness and strength for servo engines and automated frameworks. Built with aerospace-grade 6061-T6 aluminum combination, this mounting plate gives the idealize establishment for your basic gear. With prevalent levelness resilience of ≤0.05mm and dark anodized wrap up, our mounting plates guarantee ideal execution in requesting mechanical situations. Each plate experiences thorough quality control to meet the most noteworthy industry standards.

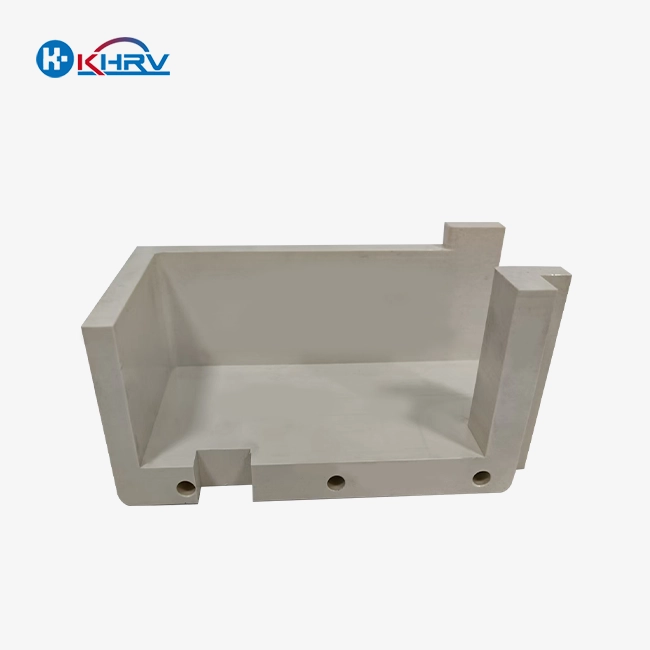

Product Introduction

Our Demonstrate TV00000200A01 speaks to the apex of exactness mounting innovation. This Aluminum Engine Mounting Plate serves as a center basic component for mechanical robot joint modules and servo engine establishments. The plate gives high-rigidity mounting references whereas keeping up lightweight characteristics basic for present day robotization systems.

Key highlights incorporate optimized auxiliary plan with standard interfacing that altogether diminish get together time. The dark anodized treatment upgrades erosion resistance and gives an alluring, proficient wrap up. We back both test administrations and comprehensive OEM/ODM customization to meet your particular requirements.

Main Advantages

Lightweight Plan Fabulousness: Our aerospace-grade aluminum development decreases robot idleness whereas keeping up basic astuteness. This deciphers to moved forward framework responsiveness and vitality efficiency.

Uncompromising Accuracy: Progressed CNC machining conveys fabulous geometric resistances guaranteeing precise transmission arrangement. Your engines will perform at top proficiency with negligible vibration.

Rapid Integration: Astutely planned mounting interfacing and standard association focuses streamline your establishment handle, sparing important generation time.

Superior Warm Administration: Inventive empty rib plan and coordinates warm scattering grooves progress warm execution by 25%, culminate for high-power engine applications.

Specifications

| Parameter | Specification |

|---|---|

| Model | TV00000200A01 |

| Material | 6061-T6 Aluminum Alloy |

| Flatness | ≤ 0.05 mm |

| Surface Treatment | Black Anodized |

| Weight Reduction | >30% compared to steel alternatives |

| Heat Dissipation | 25% improvement over standard designs |

| Hole Accuracy | ±0.01mm |

| Delivery Time | 10-20 working days |

| Certification | ISO9001:2015, EU RoHS Compliant |

Why Choose Us?

Proven Skill: With 15 a long time of specialized involvement, Wuxi Kaihan Innovation brings unmatched information to accuracy fabricating. Our group incorporates experts from Singapore's driving endeavors, guaranteeing world-class quality standards.

Cost-Effective Arrangements: Advantage from China's supply chain preferences with 30%-40% taken a toll investment funds without compromising quality. Our incline generation framework maximizes effectiveness whereas keeping up excellence.

Quality Confirmation: ISO9001:2015 certification and comprehensive quality administration frameworks ensure dependable execution. Each Aluminum Engine Mounting Plate experiences strict quality control protocols.

Innovation Center: With 36% of our staff committed to investigate and 8% yearly income contributed in R&D, we hold 22 licenses reflecting our commitment to innovative headway.

Customization Process

- Requirements Analysis: Share your motor specifications and mounting requirements with our engineering team

- Design Optimization: Our experts create custom solutions perfectly matched to your application

- Prototype Development: Receive samples for testing and validation before full production

- Production Planning: Streamlined manufacturing with 10-20 working day delivery timeframe

- Quality Verification: Comprehensive testing ensures your custom plates meet exact specifications

Factory Strength

Our state-of-the-art facility specializes in precision instrument parts manufacturing with advanced CNC milling and turning capabilities. We maintain strong partnerships with global industry leaders through our proven track record of excellence.

Our aluminum motor mounting plate system includes precision testing instruments that guarantee consistent quality from design to delivery. This integrated approach ensures your mounting plates meet the most demanding specifications.

Quality Certification

We maintain rigorous quality standards through our ISO9001:2015 certified quality management system. All products comply with EU RoHS standards, ensuring environmental responsibility and global market acceptance.

Our quality control processes include dimensional verification, material testing, and surface finish inspection. This multi-layer approach guarantees that every plate meets or exceeds your performance expectations.

Transport Packaging

Professional packaging solutions protect your investment during shipping. We use custom-fitted protective materials and secure mounting to prevent damage during transport. Each package includes detailed documentation and handling instructions.

Our logistics team coordinates with reliable carriers to ensure timely delivery worldwide. Tracking information keeps you informed throughout the shipping process.

FAQ

Q: What precision levels can you achieve?

A: Our CNC machining delivers flatness ≤0.01mm/100mm and parallelism ≤0.02mm, exceeding industry standards for servo motor installations.

Q: Can you customize mounting hole patterns?

A: Yes, we provide full-size customization with CNC drilling and milling performed in single setups for ±0.01mm hole accuracy.

Q: What materials are available?

A: We primarily use 6061-T6 aluminum alloy, with 7075 aviation aluminum available for applications requiring maximum weight reduction.

Q: Do you provide samples?

A: Absolutely! Sample services help you verify our product meets your exact requirements before volume orders.

Contact Us

Ready to enhance your motor mounting solutions? Our technical team stands ready to discuss your specific requirements and provide expert recommendations. Whether you need standard aluminum motor mounting plates or custom solutions, we deliver excellence every time.

Email us at service@kaihancnc.com for detailed quotations, technical specifications, or to discuss your custom mounting plate requirements. Experience the difference that precision engineering makes in your applications.

Learn about our latest products and discounts through SMS or email