- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

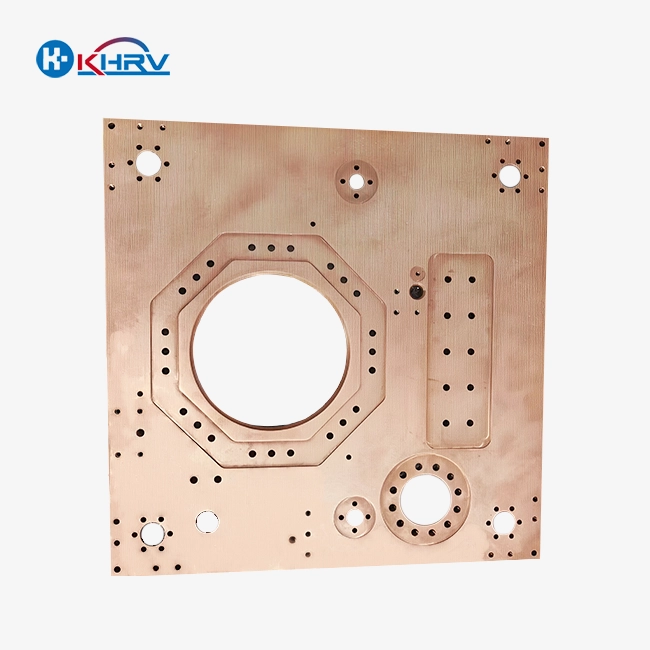

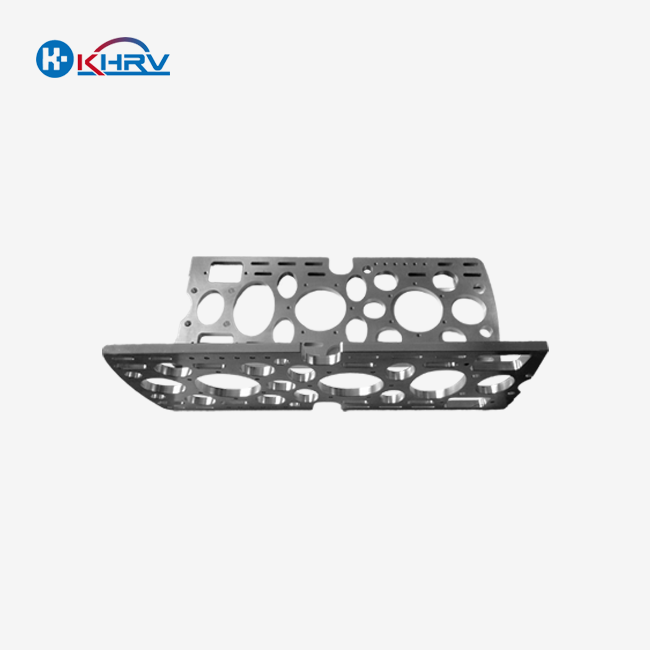

70HRC Milling Cutter

Processing: CNC milling

Applications: Industrial machinery, electronics, medical devices, automotive parts, CNC tools

Services: OEM and ODM customizations

Delivery time: 10-20 business days

Certifications: ISO 9001:2015, EU RoHS compliant

Precision and Performance: Wuxi Kaihan's 70HRC Milling Cutter

Wuxi Kaihan Technology Co., Ltd. is a leading manufacturer and supplier of high-quality 70HRC Milling Cutters. With 15 a long time of encounter in exactness machining, our items offer unparalleled execution and strength. Our progressed R&D capabilities, talented workforce, and state-of-the-art generation offices guarantee that each item meets the most noteworthy industry guidelines. Believe Wuxi Kaihan for exactness apparatuses that raise your machining operations.

Product Introduction

Our product is designed for superior performance in high-precision milling operations. Ideal for creating angled cuts and complex geometries, this tool excels in applications across manufacturing, automotive, aerospace, and mold production industries. Engineered with premium materials and cutting-edge technology, our milling cutter ensures exceptional accuracy, longevity, and consistent results.

Specifications

|

Feature

|

Description

|

|

Material

|

tungsten steel alloy

|

|

Flute Design

|

70HRC High Helix Angle Design

|

|

Cutting Edge

|

Smoother cutting, excellent chip evacuation

|

|

Diameter Range

|

1mm-20mm

|

|

Length

|

50mm-150mm

|

|

Compatibility

|

Suitable for high-speed and high-hardness machining of alloy steel and die steel with HRC 50~72.

|

|

Tolerance

|

diameter4<D≤12,(0-0.02)

12<D≤20,(0-0.03)

|

Why Choose Us?

- Superior Quality: Our products are manufactured using premium materials and advanced production techniques.

- Precision Engineering: Each cutter is designed for optimal performance and accuracy in demanding applications.

- Durability: Enhanced tool life reduces downtime and replacement frequency.

- Versatility: Suitable for a wide range of materials and machining operations.

- Cost-Effective: High performance and longevity translate to excellent ROI.

- Technical Support: Our team of experts provides guidance on tool selection and application.

Customization Process

We offer tailored solutions to meet your specific requirements. Contact us to discuss your custom product needs.

Factory Strength

At Wuxi Kaihan, we pride ourselves on our state-of-the-art manufacturing facilities. Our 15,000 square meter production area houses advanced CNC machines, precision grinding equipment, and rigorous quality control stations. Our team of skilled technicians and engineers, many with experience from top global enterprises, ensures that every 70HRC Milling Cutter meets the highest standards of quality and performance.

We invest heavily in research and development, with 36% of our staff dedicated to innovation and improvement. This commitment allows us to stay at the forefront of milling technology, continuously enhancing our products to meet the evolving needs of our customers.

Quality Certification

Our dedication to quality is reflected in our certifications:

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- OHSAS 18001:2007 Occupational Health and Safety Management System

These certifications ensure that our products meet international standards for quality, environmental responsibility, and workplace safety.

Transport Packaging

We understand the importance of protecting your investment during transit. Each product is carefully packaged in impact-resistant cases with custom foam inserts. For bulk orders, we use reinforced cartons and pallets to ensure safe transportation. Our packaging meets international shipping standards, providing protection against moisture, shock, and vibration.

FAQ

Q1: What materials can your product machine?

A1: Our milling cutters are designed to work with a wide range of materials, including steel, aluminum, titanium, and various alloys. The TiAlN coating enhances performance on harder materials.

Q2: How long does a typical product last?

A2: Tool life varies depending on usage and material. Under normal conditions, our cutters can last 30-50% longer than standard tools. Regular maintenance can further extend their lifespan.

Q3: Do you offer rush orders for products?

A3: Yes, we can accommodate rush orders for standard sizes. Please contact our sales team for expedited production and shipping options.

Q4: Can I get samples of your product before placing a bulk order?

A4: Absolutely! We offer sample units for testing. Contact us to arrange a sample order and experience the quality firsthand.

Q5: What after-sales support do you provide for products?

A5: We offer comprehensive after-sales support, including technical assistance, troubleshooting, and guidance on optimal tool usage. Our team is always ready to help you maximize the performance of your milling cutters.

Contact Us

Ready to elevate your milling operations with our high-performance 70HRC Milling Cutters? Contact our expert team today for quotes, custom solutions, or technical support. Email us at service@kaihancnc.com to start your journey towards precision machining excellence.

Learn about our latest products and discounts through SMS or email