- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Aluminum Base Plate

Flatness: ≤ 0.08 mm / 1000 mm

Heat Treatment: Stress-relieved (T651 temper)

Surface Treatment: Ordinary anodizing (natural/black)

Key Characteristics: Excellent dimensional stability, good strength

Support sample service

Support OEM,ODM customization

Delivery time: 10-20 working days

Certification: ISO9001:2015 , Complies with EU RoHS standards

Aluminum Base Plate - Precision Foundation for Your Industrial Equipment

Looking for a dependable aluminum base plate that conveys extraordinary levelness and dimensional solidness? Our premium 6061-T651 products give the idealize establishment for accuracy gear get together. Made from high-grade aluminum amalgam with stress-relieved treatment, each plate experiences thorough quality control to guarantee your ventures meet the most elevated benchmarks. With fabulous geometric resistances and prevalent fabric consistency, our products serve as the foundation for keeping up exactness over your whole framework. (101 words)

Product Introduction

Our precision-engineered products are fabricated utilizing 6061-T651 aluminum combination, known for its exceptional strength-to-weight proportion and erosion resistance. Each plate highlights remarkable levelness (≤ 0.08 mm / 1000 mm) and experiences stress-relief warm treatment to guarantee long-term dimensional stability.

These plates serve as basic mounting stages for mechanical gear, giving precise reference planes and exact mounting gaps. Whether you require standard sizes or custom setups, we provide arrangements that meet your correct specifications.

Main Advantages

Superior Flatness Control

Our progressed machining forms accomplish levelness resiliences inside 0.08mm per 1000mm, guaranteeing your hardware keeps up idealize alignment.

Excellent Material Stability

The T651 mood gives uniform stretch alleviation all through the fabric, avoiding twisting and dimensional changes over time.

Enhanced Durability

6061 aluminum amalgam offers great erosion resistance and mechanical properties, expanding your equipment's benefit life.

Precision Manufacturing

State-of-the-art CNC machining centers convey steady quality and tight resistances over all dimensions.

Specifications

| Property | Specification |

|---|---|

| Material | 6061-T651 Aluminum Alloy |

| Flatness | ≤ 0.08 mm / 1000 mm |

| Heat Treatment | Stress-relieved (T651 temper) |

| Surface Treatment | Anodizing (Natural/Black) |

| Maximum Size | 1500×800×300mm |

| Dimensional Tolerance | ±0.05mm |

| Surface Roughness | Ra 1.6μm |

| Delivery Time | 10-20 working days |

Why Choose Us?

15 Years of Manufacturing Excellence

Since 2011, we've perfected our aluminum machining processes, serving global industry leaders with consistent quality.

Advanced Technology Team

Our engineering team includes 36% research personnel, ensuring innovative solutions for complex requirements.

Cost-Effective Solutions

Benefit from China's supply chain advantages with 30-40% cost savings without compromising quality.

Comprehensive Quality Systems

ISO9001:2015 certification and strict quality control guarantee reliable performance in every aluminum base plate.

Customization Process

Step 1: Requirement Analysis

Share your technical drawings, dimensions, and specific application needs with our engineering team.

Step 2: Design Optimization

We review your specifications and suggest improvements for enhanced performance and cost efficiency.

Step 3: Prototype Development

Receive sample parts for testing and validation before full production begins.

Step 4: Production & Quality Control

Each plate undergoes precision machining and thorough inspection to meet your exact standards.

Factory Strength

Our 15,000 square meter office houses progressed CNC processing centers competent of taking care of complex geometries and tight resistances. With greatest preparing measurements of 1500×800×300mm, we oblige both standard and curiously large requirements.

Our incline generation framework, combined with gifted professionals and robotized quality frameworks, guarantees steady yield and on-time conveyance. We keep up 22 licenses in exactness fabricating, reflecting our commitment to innovative advancement.

Quality Certification

- ISO9001:2015 Quality Management System

- EU RoHS Compliance for environmental safety

- Material Certificates for all aluminum alloy batches

- Dimensional Inspection Reports for every shipment

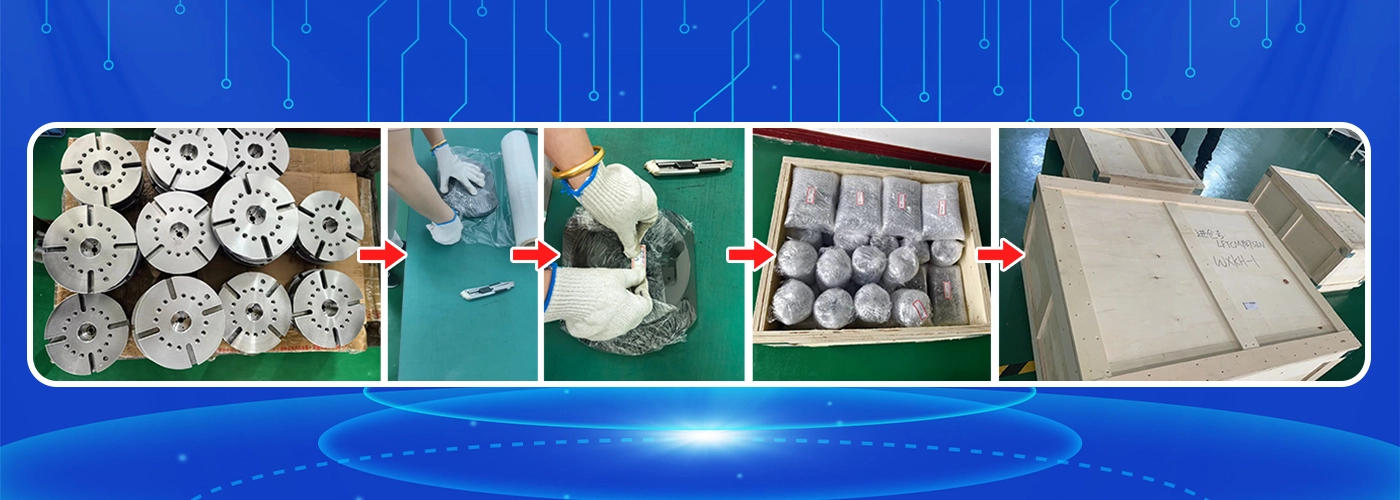

Transport Packaging

Each aluminum base plate is carefully wrapped in defensive film and secured in custom wooden cartons. We utilize shock-absorbing materials to avoid harm amid shipping. All bundles incorporate point by point assessment certificates and dealing with instructions.

For worldwide shipments, we give total documentation counting commercial solicitations, pressing records, and certificates of root to guarantee smooth traditions clearance.

FAQ

Q: Do you offer vibration aging treatment?

A: Yes, our vibration aging treatment eliminates ≥90% of processing stress, ensuring geometric stability with flatness changes ≤0.01mm/year.

Q: What's the maximum size you can machine?

A: Our CNC equipment handles sizes up to 1500×800×300mm. Larger dimensions can be sectioned and precision-joined.

Q: Can you provide custom hole patterns?

A: Absolutely. We machine custom mounting holes, slots, and features according to your drawings.

Q: What's your minimum order quantity?

A: We accept orders starting from single pieces, with competitive pricing for larger quantities.

Contact Us

Ready to discuss your aluminum base plate requirements? Our technical team is here to help you find the perfect solution. Whether you need standard sizes or custom configurations, we'll provide expert guidance and competitive pricing.

Email: service@kaihancnc.com

Contact us today for technical specifications, pricing, or to request samples. We're committed to delivering precision-engineered solutions that exceed your expectations.

Learn about our latest products and discounts through SMS or email