- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

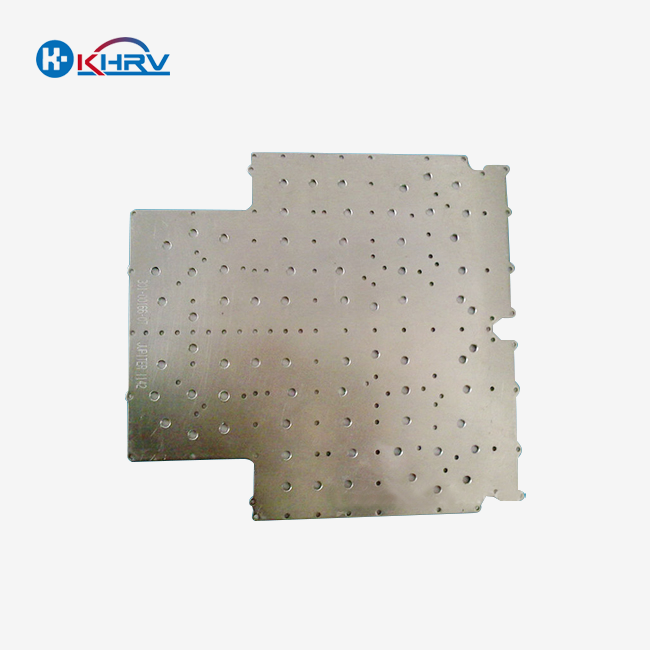

Laser Equipment Rotating Base

2. Weight: 0.22kg

3. Surface Treatment: Sandblasting (roughness Ra1.6-Ra3.2) + Black Anodizing (film thickness ≥8μm)

4. Tolerance Standard: Unspecified dimensions are compliant with GB/T1804-m

5. Machining View: First-person view

6. Key Geometric Tolerances: Rotational coaxiality ≤0.02mm, Mounting hole position tolerance ±0.015mm

7. Environmental Adaptability: Operating temperature -40℃~120℃, humidity ≤90% (non-condensing)

8. Process Requirements: Surface free of scratches/abrasions, all burrs and flash removed, machined according to model dimensions

Indexing Accuracy: ±30 arcseconds (Arc-sec)

Main Hole Diameter Tolerance: H7

Indexing Hole Position Tolerance: ±0.015 mm

Surface Treatment: Passivation

Key Characteristics: High rigidity, high wear resistance, rust prevention

High-Precision Laser Equipment Rotating Base - Professional CNC Machined Solution

Product Introduction

Looking for a solid pivoting base for your laser framework? Our laser equipment rotating base conveys uncommon accuracy and toughness for your mechanical applications. Designed from premium 6061 aluminum amalgam, this pivoting base gives smooth 360° turn capabilities whereas keeping up tight resiliences. Whether you're working with laser cutting, stamping, or review gear, this Laser Hardware Pivoting Base guarantees reliable execution and long-lasting unwavering quality. The lightweight plan diminishes framework stack whereas the dark anodized wrap up anticipates obstructions with your laser bar path.

Main Advantages

Lightweight Yet Robust Design

Our turning base weighs as it were 0.22kg, essentially decreasing stack on your laser equipment's conclusion effector. The 6061 aluminum amalgam development gives great strength-to-weight proportion, idealize for high-dynamic revolution applications.

Superior Anti-Interference Properties

The sandblasting and dark anodizing treatment viably minimizes laser reflection impedances. This guarantees your optical way remains clear and exact all through operation cycles.

Exceptional Precision Standards

With rotational coaxiality ≤0.02mm and mounting gap position resilience ±0.015mm, you get the precision your laser applications request. Unspecified measurements comply with GB/T1804-m standards.

Enhanced Durability

Our specialized surface treatment gives salt shower resistance ≥480h and passes thorough Taber scraped spot tests. The oxide layer keeps up ≥5MPa attachment quality, guaranteeing long-term performance.

Specifications

| Parameter | Specification |

|---|---|

| Material | 6061 Aluminum Alloy |

| Weight | 0.22kg |

| Surface Treatment | Sandblasting + Black Anodizing |

| Film Thickness | ≥8μm |

| Operating Temperature | -40℃ to 120℃ |

| Humidity Range | ≤90% (non-condensing) |

| Rotational Coaxiality | ≤0.02mm |

| Mounting Hole Tolerance | ±0.015mm |

| Indexing Accuracy | ±30 arcseconds |

| Rotation Range | 360° continuous |

| Main Hole Tolerance | H7 |

Why Choose Us?

15 Years of Manufacturing Excellence

Established in 2011, Wuxi Kaihan Innovation brings over 15 a long time of specialized involvement in exactness CNC machining. Our group incorporates experts from Singapore's driving undertakings, guaranteeing world-class quality standards.

Cost-Effective Solutions

Benefit from China's supply chain points of interest with 30%-40% fetched investment funds without compromising quality. Our incline generation framework and productive forms provide extraordinary value.

Research & Development Focus

With 36% of our staff committed to investigate and 8% yearly income contributed in R&D, we ceaselessly enhance. Our 22 licenses illustrate our commitment to progressing laser gear technology.

Quality Certifications

Our ISO9001:2005 Quality Administration Framework certification guarantees steady quality control all through generation. Each Laser Gear Pivoting Base experiences thorough testing some time recently shipment.

Customization Process

Step 1: Requirements Analysis

Share your particular application needs, counting mounting interface drawings, turn point prerequisites, and stack specifications.

Step 2: Design Optimization

Our building group makes custom arrangements, altering mounting gaps, turn limits, and basic fortifications as needed.

Step 3: Prototype Development

We create models for testing and approval, guaranteeing culminate compatibility with your laser equipment.

Step 4: Production & Quality Control

Full-scale fabricating starts with comprehensive quality checks at each stage.

Step 5: Delivery & Support

Careful bundling and shipping, taken after by continuous specialized bolster for ideal performance.

Factory Strength

Our state-of-the-art office highlights progressed CNC machining centers and exactness testing disobedient. We keep up strict quality control conventions and incline generation frameworks. Our organizations with worldwide industry pioneers approve our fabricating capabilities and reliability.

Quality Certification

- ISO9001:2005 Quality Management System

- Comprehensive quality testing protocols

- 22 patents in precision manufacturing

- Salt spray resistance testing ≥480h

- Taber abrasion resistance certification

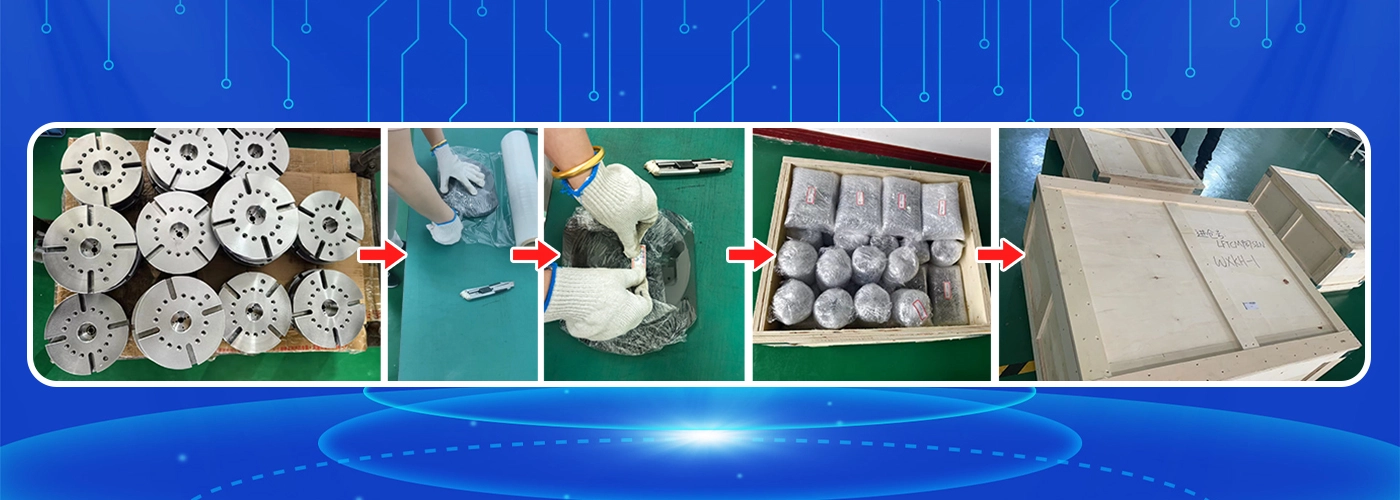

Transport Packaging

Each laser equipment rotating base gets defensive bundling planned to anticipate harm amid shipping. Anti-static materials ensure touchy surfaces, whereas custom froth embeds guarantee secure transport. We give following data and arrange conveyance to meet your extend timelines.

FAQ

Q: Can this rotating base handle different laser power levels?

A: Yes, it's suitable for low-to-medium power laser equipment (typically below 500W). For higher power applications, we offer reinforced versions with enhanced heat dissipation.

Q: How durable is the black anodized coating?

A: Our hard anodizing process creates a coating with ≥5MPa adhesion strength. It passes wear resistance tests with less than 0.03mm wear after 500 revolutions.

Q: Can you customize mounting holes for our specific equipment?

A: Absolutely! We can customize mounting holes to match your equipment interface with ±0.015mm tolerance. Simply provide your interface drawings.

Q: What's the maximum rotation angle available?

A: Standard models offer 360° continuous rotation. Custom limit angles from 0° to 180° or 0° to 270° are available with positioning pin holes for angle fixation.

Contact Us

Ready to enhance your laser system's precision and reliability? Our technical team is ready to discuss your specific requirements and provide customized solutions.

Email: service@kaihancnc.com

Contact us today to learn more about our precision-engineered rotating bases and how they can optimize your laser equipment rotating base performance.

Learn about our latest products and discounts through SMS or email