- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Custom Hex Head Cap Screw

2. Core structure: External hexagonal head + full thread (head size, screw length, and thread specifications can all be customized, such as M8-M20, length 20-200mm);

3. Customizable processes/surface treatments: Zinc plating, nickel plating, blackening, etc. (to suit different rust prevention/wear resistance requirements); thread precision can match GB/ISO standards;

4. Universal applicability: Suitable for fastening components in various industrial equipment such as CNC equipment, automated production lines, tooling fixtures, and construction machinery.

Custom Hex Head Cap Screw - Professional Industrial Fastening Solutions

Product Introduction

Welcome to Wuxi Kaihan Technology's custom hex head cap screw arrangements. When your mechanical hardware requests exactness affixing components that standard screws cannot give, our product fabricating mastery conveys precisely what you require. With over 15 a long time of specialized encounter, we get it that each application has one of a kind prerequisites. Our building group works closely with you to make affixing arrangements that superbly coordinate your specifications.

Our hex head cap screws include customizable materials counting Review 8.8/10.9 auxiliary steel and 304/316 stainless steel. The center structure combines an outside hexagonal head with full threading capabilities. You can indicate head estimate, screw length from 20-200mm, and string details extending from M8-M20. Surface medications incorporate zinc plating, nickel plating, and darkening forms to meet your particular natural requirements.

Main Advantages

Flexible Customization Options

You get total control over measurements, materials, and fabricating forms. Our group adjusts each angle to coordinate your equipment's correct securing requirements.

Wide Industrial Compatibility

These latches work consistently over CNC hardware, computerized generation lines, tooling installations, and development apparatus applications.

Superior Material Selection

Choose from high-grade auxiliary steel or corrosion-resistant stainless steel choices. Each fabric is chosen based on your quality and natural demands.

Precision Thread Manufacturing

Our threading meets GB/ISO measures with customizable accuracy levels. This guarantees culminate fit and ideal execution in your applications.

Specifications

| Parameter | Options | Range |

|---|---|---|

| Material | Grade 8.8/10.9 Steel, 304/316 Stainless Steel | Multiple grades available |

| Thread Size | Metric Threading | M8 - M20 |

| Length | Customizable | 20mm - 200mm |

| Head Type | External Hexagonal | Various sizes |

| Surface Treatment | Plating Options | Zinc, Nickel, Blackening |

| Threading | Full Thread | GB/ISO Standards |

| Customization Time | Standard Parameters | 7-10 Business Days |

Why Choose Us?

15 Years of Manufacturing Excellence

Our established reputation comes from consistent quality delivery. Research personnel comprise 36% of our staff, ensuring innovative solutions for your challenges.

Cost-Effective Solutions

You benefit from China's supply chain advantages with 30-40% cost savings. This doesn't compromise quality - it enhances your project economics.

Advanced Quality Systems

ISO9001:2005 certification backs our quality management processes. Every custom hex head cap screw undergoes strict quality control before delivery.

Technical Expertise

Our team includes professionals from Singapore's leading enterprises. We hold 22 patents and invest 8% of annual revenue in research and development.

Customization Process

Step 1: Requirements Discussion

Contact our engineering team with your specifications. We'll review your application requirements and recommend optimal solutions.

Step 2: Technical Consultation

Our experts analyze your fastening needs. We consider operating conditions, load requirements, and environmental factors.

Step 3: Custom Design

We create detailed specifications for your custom hex head cap screw. This includes material selection, dimensions, and surface treatments.

Step 4: Manufacturing & Quality Control

Production begins using precision CNC equipment. Each component undergoes comprehensive testing and inspection.

Step 5: Delivery & Support

Your custom fasteners arrive ready for installation. Our technical team provides ongoing support for any questions.

Factory Strength

Our Jiangsu Province facility represents advanced manufacturing capabilities. CNC milling and turning equipment ensures precision across every component. Comprehensive testing instruments verify quality standards throughout production.

The lean production system optimizes efficiency while maintaining quality. This approach has built strong partnerships with global industry leaders. Our manufacturing capacity scales to meet your volume requirements efficiently.

Quality Certification

ISO9001:2005 Quality Management System certification demonstrates our commitment to excellence. Strict quality control processes ensure reliable product performance. Each batch receives comprehensive testing before shipment approval.

Our quality systems cover material verification, dimensional inspection, and performance testing. Documentation accompanies every order for complete traceability.

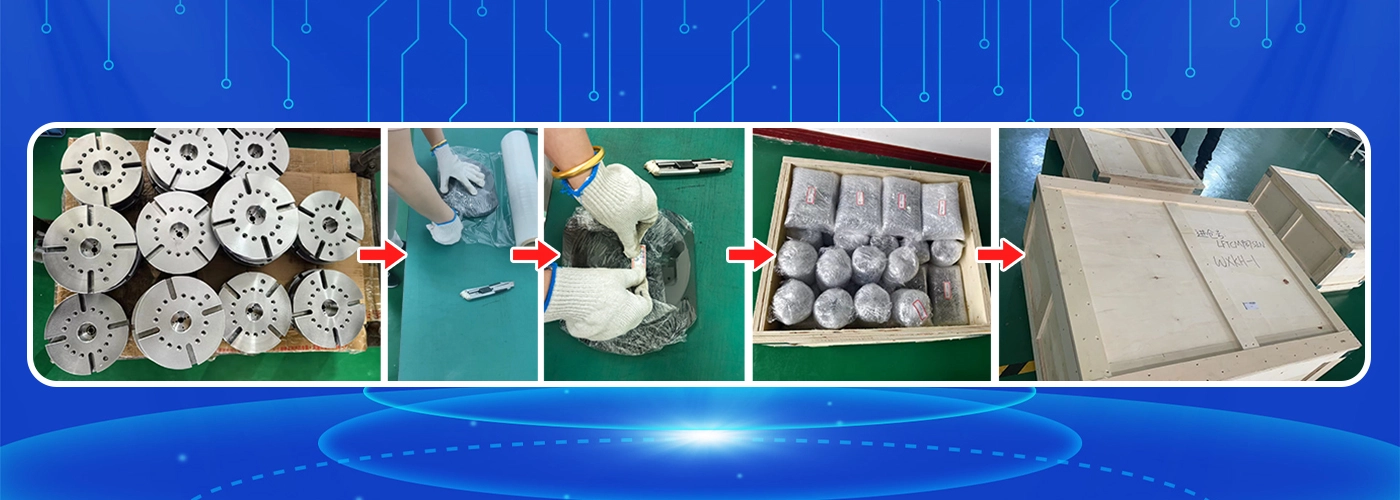

Transport Packaging

Protective packaging preserves your fasteners during shipping. Custom foam inserts prevent damage and organize components efficiently. Clear labeling identifies specifications and quantities for easy inventory management.

International shipping options ensure timely delivery worldwide. Tracking information keeps you informed throughout the delivery process.

FAQ

Q: What materials work best for high-stress applications?

A: Grade 10.9 structural steel provides excellent strength for demanding applications. Stainless steel 316 offers superior corrosion resistance in harsh environments.

Q: Can you match existing fastener specifications?

A: Yes, send us your current specifications or samples. We'll create matching product solutions with any improvements you need.

Q: What's the minimum order quantity?

A: We accommodate both prototype quantities and production volumes. Contact us to discuss your specific requirements.

Q: Do you provide technical drawings?

A: Detailed technical drawings accompany every custom order. These include all dimensions, tolerances, and material specifications.

Contact Us

Ready to discuss your custom fastening needs? Our engineering team is here to help you find the perfect solution.

Email: service@kaihancnc.com

Contact us today for technical consultation and competitive pricing. We'll work with you to create custom hex head cap screw solutions that exceed your expectations.

Learn about our latest products and discounts through SMS or email