- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

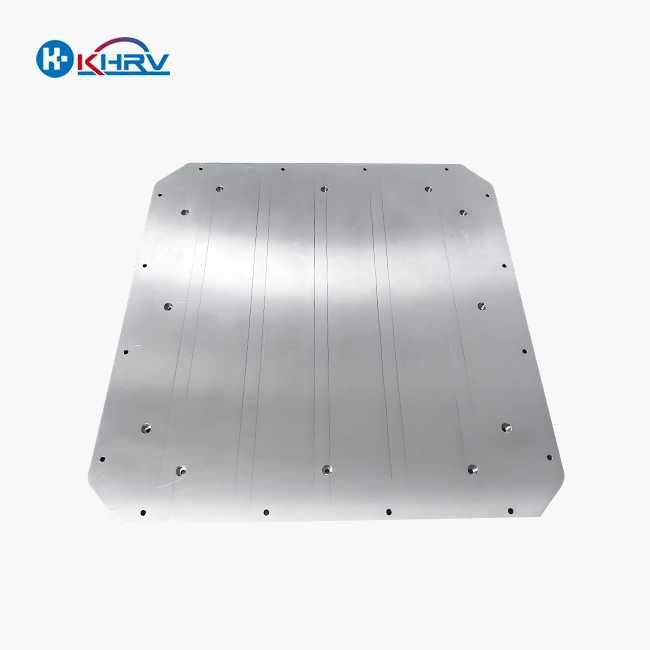

Modular Fixture Plate

Hole tolerance: ±0.01mm;

Flatness: ≤0.008mm/100mm;

Machining process: CNC milling + precision grinding;

Interface: Ball lock clamp, zero-point quick-change system

Support sample service

Support OEM,ODM customization

Certification: ISO9001:2015 , Complies with EU RoHS standards

Modular Fixture Plate - Precision Tooling Solutions for Industrial Automation

Product Introduction

Change your fabricating productivity with our precision-engineered modular fixture plate. Planned particularly for mechanical mechanical frameworks and computerized generation lines, this high-performance tooling arrangement conveys remarkable exactness and flexibility. Our installation plates highlight standardized multi-hole formats that back fast clamping and multi-station exchanging, making them perfect for situating and installation establishment in robot generation lines, accuracy machining, and computerized testing hardware. With CNC processing and accuracy pounding fabricating forms, you get dependable execution that meets the most requesting mechanical applications.

Main Advantages

Quick and Effective Setup: Encounter phenomenal efficiency with our standardized multi-hole format. Congruous with ball locks and zero-point quick-change installations, your clamping and exchanging time decreases to fair 2 minutes or less. This effectiveness boost increments tooling reuse rates by 60%, altogether lessening downtime.

Stable Accuracy Execution: Accomplish steady comes about with gap resistance of ±0.01mm and levelness ≤0.008mm/100mm. This accuracy guarantees dependable situating over numerous workstations, keeping up quality benchmarks all through your generation process.

Superior Fabric Choices: Select between lightweight 6061-T6 aluminum or tough 304 stainless steel development. Each fabric choice adjusts to distinctive stack prerequisites and working conditions, giving adaptability for your particular applications.

Universal Compatibility: Our modular fixture plate coordinated consistently with standard robot tooling frameworks. We back customization of non-standard sizes and gap formats to coordinate your correct requirements.

Specifications

| Parameter | Specification |

|---|---|

| Material Options | 6061-T6 Aluminum / 304 Stainless Steel |

| Hole Tolerance | ±0.01mm |

| Flatness | ≤0.008mm/100mm |

| Manufacturing Process | CNC Milling + Precision Grinding |

| Interface Types | Ball Lock Clamp, Zero-Point Quick-Change System |

| Load Capacity (Static) | ≥600kg (Aluminum), ≥1000kg (Stainless Steel) |

| Surface Treatment | Hard Anodizing (Aluminum), Passivation/Nickel Plating (Steel) |

| Certifications | ISO9001:2015, EU RoHS Compliant |

Why Choose Us?

Cost-Effective Solutions: Benefit from China's supply chain advantages with 30%-40% cost savings without compromising quality. Our competitive pricing helps you maximize your return on investment.

Proven Experience: With 15 years of industry expertise, we understand your challenges. Our team includes professionals from Singapore's top enterprises, ensuring world-class solutions.

Quality Assurance: Our ISO9001:2015 certification and comprehensive quality management system guarantee consistent, reliable products that meet international standards.

Innovation Focus: We invest 8% of annual revenue in R&D and hold 22 patents. Our research personnel comprise 36% of our staff, driving continuous improvement and innovation.

Customization Process

- Consultation: Contact our technical team to discuss your specific requirements

- Design Review: We analyze your application and propose optimal solutions

- Prototype Development: Create samples for testing and validation

- Production: Manufacture using our advanced CNC equipment and quality control systems

- Quality Testing: Comprehensive inspection ensures specification compliance

- Delivery: Secure packaging and reliable shipping to your location

Factory Strength

Our state-of-the-art office specializes in investigate, improvement, generation, and deals of accuracy instrument parts and CNC tooling. Progressed generation gear and accuracy testing disobedient guarantee the best involvement from plan to conveyance. Our incline generation framework empowers solid organizations with worldwide industry leaders.

Quality Certification

We keep up strict quality control through different certification frameworks. Our ISO9001:2015 certification illustrates our commitment to quality administration brilliance. All items comply with EU RoHS benchmarks, guaranteeing natural obligation and administrative compliance.

Transport Packaging

Professional bundling ensures your venture amid shipping. We utilize custom defensive materials and secure bundling strategies to anticipate harm amid travel. Each Secluded Installation Plate gets person assurance with fitting padding materials.

FAQ

Q: What types of quick-change fixtures are supported?

A: Our plates are compatible with mainstream systems including ball lock fixtures, zero-point quick-change systems, and T-slot fixtures. We can customize hole layouts to match your specific fixture interfaces.

Q: Can hole configurations be customized?

A: Absolutely! We offer full customization of hole number, diameter, and spacing according to your requirements. Minimum hole diameter is φ5mm with ±0.01mm tolerance.

Q: What surface treatments are available?

A: We offer hard anodizing for aluminum plates (wear and corrosion resistant) and passivation or nickel plating for stainless steel options to meet various working condition requirements.

Q: What is the typical lead time?

A: Standard configurations ship within 7-10 days. Custom modular fixture plate orders typically require 15-20 days depending on complexity.

Contact Us

Prepared to improve your generation productivity? Our modular fixture plate are here to offer assistance you select the culminate arrangement for your applications.

Email: service@kaihancnc.com

Contact us today for technical consultation, custom quotes, or sample requests. We provide comprehensive pre-sales and after-sales support to ensure your success.

Learn about our latest products and discounts through SMS or email