- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

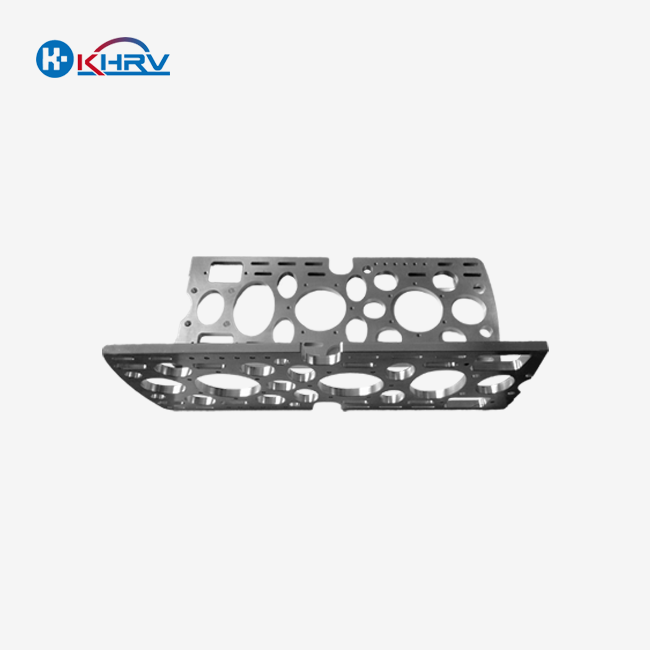

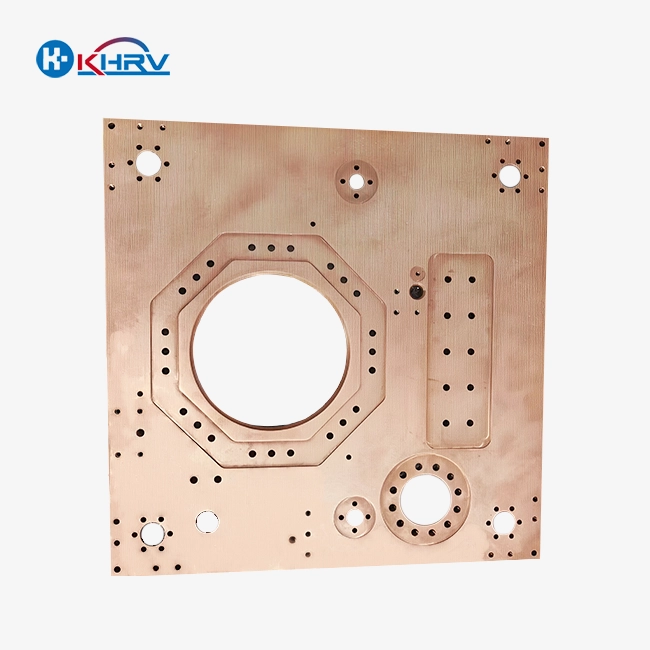

Precision CNC Turning Steel Parts

Processing method: CNC turning,Precision grinding,EDM,Surface hard anodizing,Galvanizing and chrome plating etc.

Application: Industrial equipment,Electronic appliances,Medical equipment,Auto parts,CNC tools

Support sample service

Support OEM,ODM customization

Delivery time: 10-20 working days

Certification: ISO9001:2015 , Complies with EU RoHS standards

Precision CNC Turning Steel Parts: Elevate Your Manufacturing with Wuxi Kaihan

At Wuxi Kaihan Technology Co., Ltd., we're your trusted partner for high-quality Precision CNC Turning Steel Parts. With 15 a long time of ability in R&D and fabricating, we provide components that meet the demanding benchmarks of worldwide industry pioneers. Our progressed CNC turning capabilities guarantee tight resiliences, prevalent surface wraps up, and reliable quality for your basic applications. Whether you require parts for car, aviation, or mechanical apparatus, our precision-engineered steel components are planned to raise your fabricating processes.

Product Introduction

Our items are created to meet the requests of cutting edge fabricating. Utilizing state-of-the-art CNC machines and premium steel combinations, we deliver components with unparalleled exactness and unwavering quality. From basic shafts to complex geometries, our parts are custom fitted to your correct determinations, guaranteeing consistent integration into your generation lines.

Specifications

| Feature | Description |

|---|---|

| Materials | Stainless Steel, Alloy Steel, Carbon Steel |

| Tolerances | As tight as ±0.005mm |

| Surface Finish | Ra 0.2-3.2 μm |

| Diameter Range | 5mm - 300mm |

| Length Range | Up to 1000mm |

| Production Capacity | 100,000+ units/month |

| Quality Standard | ISO 9001:2015 certified |

Why Choose Us?

- Advanced Technology: Our CNC turning centers feature the latest in precision machining technology.

- Quality Assurance: Rigorous quality control processes ensure consistent, defect-free parts.

- Cost-Effective Solutions: Lean manufacturing practices allow us to offer competitive pricing without compromising quality.

- Flexible Production: We accommodate both high-volume orders and small batch runs with equal efficiency.

- Technical Expertise: Our engineering team provides DFM support to optimize your designs for manufacturability.

Customization Process

We offer a streamlined customization process, from initial concept to final production, ensuring your unique requirements are met with precision and care.

Factory Strength

Our state-of-the-art facility in Jiangsu Province houses advanced CNC turning equipment and a team of skilled machinists. With a research staff comprising 36% of our workforce and an annual R&D investment of 8% of our revenue, we're constantly innovating to deliver cutting-edge solutions. Our lean production system and 22 patents underscore our commitment to efficiency and innovation in precision part manufacturing.

Quality Certification

We hold ISO 9001:2015 certification, ensuring our quality management system meets international standards. Additionally, we comply with industry-specific certifications such as IATF 16949 for automotive and ISO 13485 for medical device components, guaranteeing the highest level of quality and reliability in our Precision CNC Turning Steel Parts.

Transport Packaging

Our parts are carefully packaged to prevent damage during transit. We use custom-designed containers, anti-corrosion treatments, and shock-absorbing materials to ensure your precision components arrive in perfect condition, ready for immediate use in your production processes.

FAQ

Q: What is the minimum order quantity (MOQ) for the products?

A: Our MOQ varies depending on the complexity and size of the part. For standard components, we typically require a minimum of 100 pieces, but we're flexible and can discuss options for smaller quantities.

Q: Can you provide material certifications for your steel parts?

A: Absolutely. We provide full material traceability and certifications for all our steel components, ensuring compliance with your industry standards and quality requirements.

Q: What is your typical lead time for the products?

A: Lead times vary based on order volume and complexity. For standard parts, we typically deliver within 2-4 weeks. For custom or high-volume orders, please contact us for a specific timeline.

Q: Do you offer prototyping services before full production?

A: Yes, we provide rapid prototyping services to validate designs and ensure perfect fit and function before moving to full-scale production of your products.

Q: How do you ensure consistent quality across large production runs?

A: We employ statistical process control (SPC), regular quality checks, and automated inspection systems to maintain consistent quality throughout production. Our ISO 9001:2015 certified processes ensure reliability across all order sizes.

Contact Us

Ready to elevate your manufacturing with our Precision CNC Turning Steel Parts? Contact our expert team today for quotes, technical support, or custom inquiries. Reach us at service@kaihancnc.com and experience the Wuxi Kaihan difference in precision machining.

Learn about our latest products and discounts through SMS or email