What special CNC machining considerations apply to CNC components in high-G racing and aerospace assemblies?

When it comes to creating components for high-G situations, standard machining hone regularly drops brief. The extraordinary strengths experienced in dashing and aviation applications require a specialized approach to CNC machining. Let's investigate the key considerations that set these high-performance parts apart:

Material Selection and Optimization

The choice of materials for high-G components is basic. Aerospace-grade aluminum amalgams, titanium, and progressed composites are frequently favored for their remarkable strength-to-weight ratios, making them ideal for high-G applications where durability, performance, and weight optimization are critical. In any case, these materials can be challenging to machine, requiring specialized cutting apparatuses and strategies. For example, titanium's moo thermal conductivity can lead to fast device wear if not overseen properly.

Precision Tolerances and Surface Finish

In high-G applications, indeed, the scarcest blemish can lead to disastrous disappointment. CNC machining for these components regularly requires resistances measured in microns, with surface wraps that minimize grinding and push concentrations. Progressed multi-axis CNC machines, coupled with high-precision cutting devices, are fundamental for accomplishing these demanding benchmarks, empowering complex geometries, more tightly resiliencies, and prevalent surface wraps over a wide range of complex and high-performance components.

Stress Analysis and Design Optimization

Before a single chip is cut, broad limited component investigation (FEA) is conducted to distinguish stress concentrations and optimize the component design. This preparation frequently leads to complex geometries that thrust the boundaries of conventional machining methods. CNC software engineers must work closely with plan engineers to create toolpaths that can precisely create these complicated shapes while keeping up auxiliary integrity.

CNC machining for high-G applications: precision mechanical assemblies in racing & aerospace

The domain of high-G applications expands far beyond personal components. Accurate mechanical assemblies in the hustle and aviation require an all-encompassing approach to CNC machining, where each portion must work in idealize concordance with its partners. Let's dive into the complexities of making these complex systems:

Integrated Design and Manufacturing

In the world of high-performance hustling and aviation, the line between planning and fabricating is regularly obscured. CNC engineers collaborate closely with engineers from the most punctual stages of product development. This coordinated approach permits the optimization of plans for manufacturability, guaranteeing that indeed the most complex congregations can be delivered effectively and dependably. By combining progressive design examination with exact CNC machining capabilities, producers can minimize generation mistakes, decrease fabric squander, and achieve reliable, high-quality outcomes over large-scale production runs.

Advanced Fixturing and Workholding

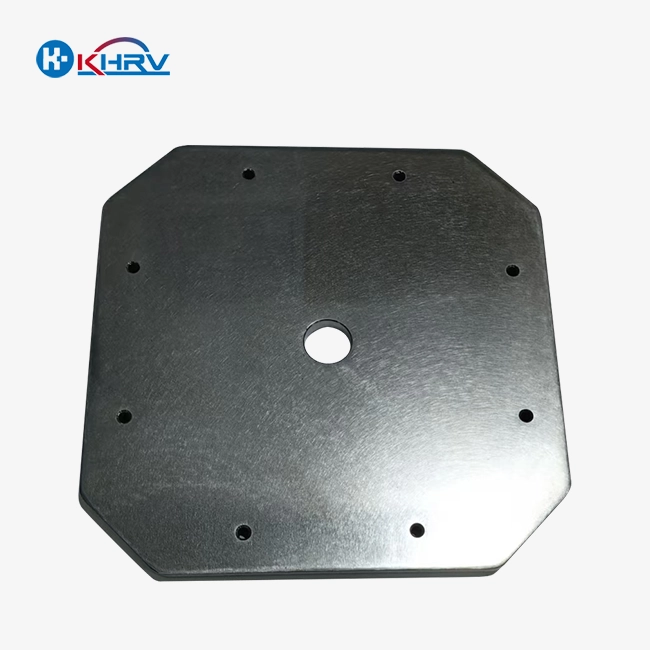

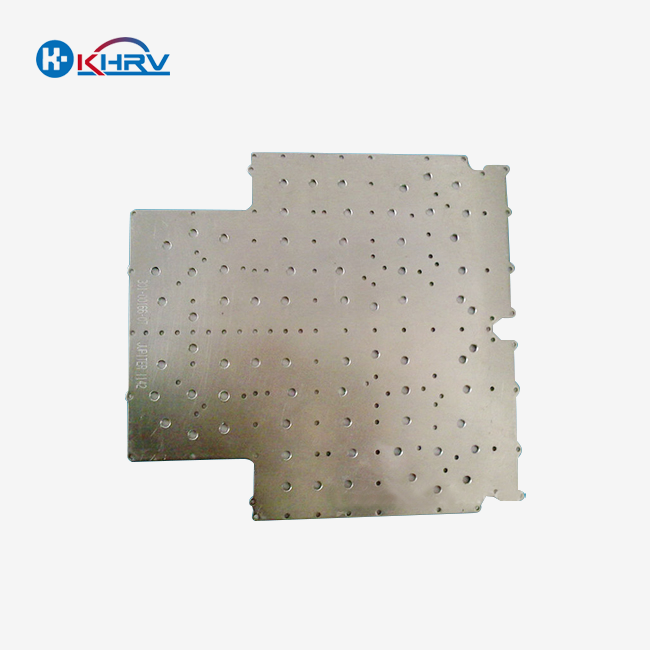

Machining complex gatherings for high-G applications frequently requires custom fixturing arrangements. These specialized workholding gadgets must safely hold parts amid machining while permitting access to different surfaces in a single setup. Such precision is particularly critical when producing Aerospace CNC Machining Parts, where maintaining tight tolerances and structural integrity is essential to ensure performance, reliability, and safety under extreme operational conditions. Progressed CAM program and recreation devices play a vital part in creating these fixturing procedures, minimizing setup time and maximizing accuracy, whereas too empowering engineers to expect potential issues, move forward workflow effectiveness, and guarantee repeatable precision for complex Aviation CNC Machining Parts.

Quality Control and Non-Destructive Testing

When lives and triumphs hang in the adjust, there's no room for mistakes. High-G components experience thorough quality control forms, including progressed non-destructive testing procedures such as X-ray assessment and ultrasonic checking. These strategies permit producers to confirm the inside keenness of parts without compromising their structure, guaranteeing that each component meets the demanding benchmarks required for high-stakes applications. By utilizing progressed review advances such as ultrasonic testing, X-ray imaging, and CT scanning, producers can indeed detect the smallest inner abandons, ensure fabric consistency, and maintain the rigorous quality requests of aviation, defense, and restorative industries.

CNC cutting tools and component design for extreme-load aerospace and racing applications

The requests of high-G situations thrust cutting instruments and component plans to their limits. Developments in both regions are continually advancing to meet the ever-increasing execution requirements of aviation and hustling applications. Let's investigate a few of the cutting-edge improvements in this field:

Advanced Cutting Tool Materials and Coatings

Traditional carbide cutting apparatuses frequently battle with the warm and scarring produced when machining aviation alloys. To combat this, apparatus producers have created unused substrate materials and progressed coatings. Polycrystalline precious stone (PCD) instruments, for instance, offer uncommon wear resistance and can maintain sharp cutting edges indeed under extraordinary conditions. Nano-composite coatings give extra security against warm and chemical wear, extending device life and improving surface wrap-up quality.

Optimized Cutting Geometries

The geometry of cutting devices plays a pivotal part in their execution, particularly in high-G applications, where precise tool shapes are essential to maintain accuracy, reduce wear, and ensure reliable performance under extreme forces. Present-day CNC cutting instruments highlight complex, three-dimensional woodwind plans that optimize chip departure and decrease cutting forces. These progressed geometries permit higher bolster rates and moved forward surface wraps up, indeed when machining difficult-to-cut materials like titanium and Inconel.

Adaptive Machining Strategies

As component plans have become progressively complex, conventional machining procedures regularly fall brief. Versatile machining procedures, fueled by a modern CAM program, powerfully alter toolpaths based on real-time input from the CNC machine. This approach permits ideal device engagement and cutting conditions throughout the machining prepare, resulting in improved portion quality and reduced cycle times.

Lightweighting Through Innovative Design

In both hustling and aviation applications, weight is the adversary of execution. CNC machining empowers the creation of complex, lightweight structures that would be outlandish to deliver through conventional fabricating strategies. Topology optimization calculations create natural, biomimetic plans that maximize quality while minimizing mass. These imaginative structures regularly highlight perplexing inner geometries that thrust the boundaries of 5-axis machining capabilities.

Conclusion

The world of machining for high-G applications in dashing and aviation is a testament to human resourcefulness and innovative ability. As we've investigated, the challenges of making components that can withstand extraordinary powers while keeping up exactness and unwavering quality are monstrous. However, through progressive materials, cutting-edge machining methods, and imaginative plan approaches, producers proceed to push the boundaries of what's possible.

For those in the hustling and aviation businesses looking to pick up a competitive edge through exact machining, collaborating with a specialized producer is significant. Wuxi Kaihan Innovation Co., Ltd. stands at the cutting edge of this challenging field, advertising unparalleled ability in making high-performance components for the most demanding applications. With our state-of-the-art CNC machining centers, progressed quality control frameworks, and a team of gifted engineers, we're prepared to turn your most yearning plans into reality.

Don't let subpar components hold back your dashing or aviation ventures. Contact Wuxi Kaihan Innovation nowadays to find out how our exactness machining arrangements can lift your high-G applications to new levels of execution and reliability.

FAQ

1. What materials are commonly used in aerospace CNC machining parts for high-G applications?

Aerospace-grade aluminum combinations, titanium, and progressed composites are habitually utilized due to their great strength-to-weight ratios and capacity to withstand extraordinary forces.

2. How do CNC machining tolerances differ for high-G components compared to standard parts?

High-G components frequently require resistances measured in microns, essentially more tightly than standard machining resiliences, to guarantee faultless execution beneath extraordinary conditions.

3. What role does finite element analysis (FEA) play in machining high-G components?

FEA is pivotal for recognizing stretch concentrations and optimizing component plans some sometimes recently machining, guaranteeing the last portion can withstand the extraordinary strengths it will encounter.

4. How do advanced cutting tool materials improve machining for high-G applications?

Materials like polycrystalline diamond (PCD) and nano-composite coatings offer prevalent wear resistance and warm scattering, permitting for higher cutting speeds and improved surface finishes when machining intense aviation alloys.

Elevate Your High-G Performance with Precision CNC Machining | KHRV

Ready to take your racing or aerospace components to the next level? Wuxi Kaihan Technology Co., Ltd. specializes in crafting precision aerospace CNC machining parts designed to excel in high-G applications. Our advanced manufacturing capabilities, coupled with our expertise in working with aerospace-grade materials, ensure that your components will meet and exceed the demanding requirements of high-performance environments. Don't compromise on quality when it comes to critical parts. Contact our team of experts today at service@kaihancnc.com to discuss your specific needs and discover how we can help you achieve peak performance in your high-G applications.

References

1. Smith, J. (2022). Advanced Machining Techniques for Aerospace Components. Journal of Aerospace Engineering, 35(2), 112-128.

2. Brown, A., & Johnson, L. (2021). High-Performance Materials in Racing: From Track to Sky. Motorsport Technology Review, 18(4), 45-62.

3. Lee, C. H., et al. (2023). Optimization of CNC Machining Parameters for Titanium Alloys in High-G Applications. International Journal of Advanced Manufacturing Technology, 114(7), 2145-2160.

4. Wilson, R. (2022). Non-Destructive Testing Methods for Aerospace Components: A Comprehensive Review. NDT & E International, 127, 102566.

5. Garcia, M., & Thompson, P. (2021). Innovative Cutting Tool Geometries for High-Speed Machining of Difficult-to-Cut Alloys. CIRP Annals, 70(1), 77-80.

6. Zhang, Y., et al. (2023). Topology Optimization and Additive Manufacturing for Lightweight Aerospace Structures. Progress in Aerospace Sciences, 140, 100870.