- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

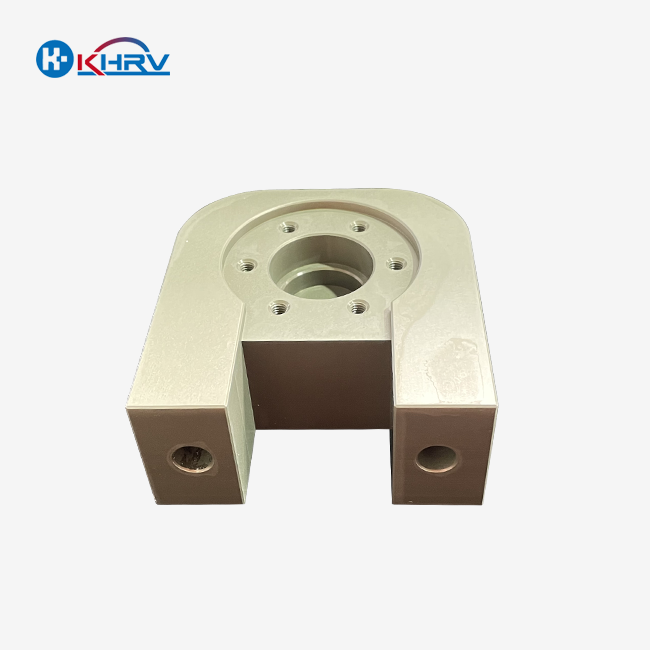

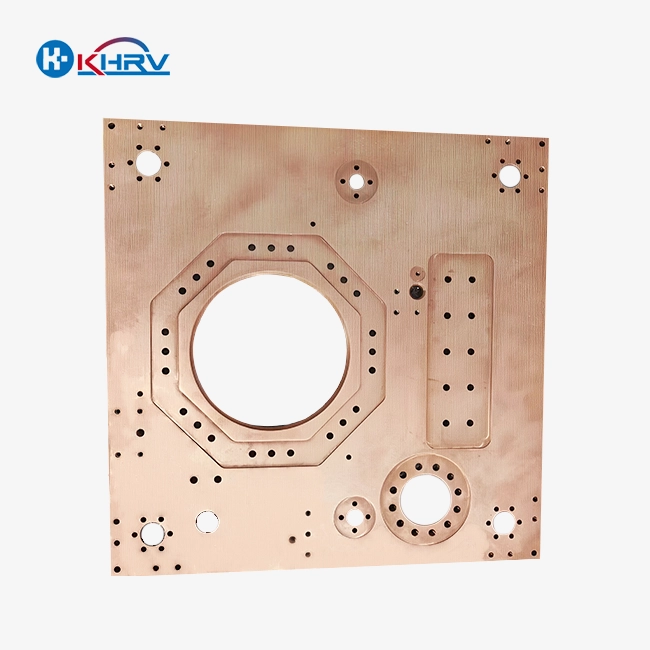

Mechanical Parts Bearing Seat

Processing method: CNC milling,CNC turning,Precision grinding,EDM

Delivery time: 10-20 working days

Certification: ISO9001:2015 , Complies with EU RoHS standards

Support sample service

Support OEM,ODM customization

Mechanical Parts Bearing Seat: Precision-Engineered for Optimal Performance

Welcome to Wuxi Kaihan Technology Co., Ltd., your trusted manufacturer and supplier of high-quality Mechanical Parts Bearing Seats. With 15 years of expertise in precision engineering, we deliver superior bearing seats that ensure smooth operation and extended equipment life. Our advanced manufacturing processes and stringent quality control measures guarantee that every product meets the highest industry standards, providing you with reliable components for your critical applications.

Product Introduction

Our products are designed to provide exceptional support and alignment for rotating shafts in various industrial machinery. Crafted from premium materials and engineered to tight tolerances, these bearing seats offer:

- Enhanced stability and load distribution

- Reduced vibration and noise

- Improved heat dissipation

- Extended bearing life

- Easy installation and maintenance

Specifications

| Feature | Description |

|---|---|

| Material | High-grade steel (AISI 1045, 4140, or custom) |

| Surface Finish | Ra 0.8-3.2 μm (adjustable) |

| Tolerance | ±0.01mm - ±0.05mm (application-dependent) |

| Size Range | 20mm - 500mm (customizable) |

| Load Capacity | Up to 50,000 N (varies by model) |

| Operating Temperature | -40°C to 120°C |

| Corrosion Resistance | Available with various surface treatments |

Why Choose Us?

- Expertise: 15 years of experience in precision part manufacturing

- Quality: ISO 9001:2015 certified with rigorous quality control

- Customization: Tailored solutions to meet your specific requirements

- Advanced Technology: State-of-the-art CNC machines for precise production

- Competitive Pricing: Cost-effective solutions without compromising quality

- Fast Turnaround: Efficient production and delivery to meet your deadlines

Customization Process

We offer a seamless customization process, from initial design consultation to final production, ensuring your product meets your exact specifications.

Factory Strength

Our 10,000 m² facility houses cutting-edge equipment, including high-precision CNC machines, CMM inspection systems, and a dedicated R&D center. Our team of skilled engineers and technicians, comprising 36% of our workforce, ensures top-notch quality and innovation in every product we produce.

Quality Certification

We hold multiple quality certifications, including ISO 9001:2015, ISO 14001:2015, and IATF 16949:2016, demonstrating our commitment to excellence and continuous improvement in manufacturing Mechanical Parts Bearing Seats.

Transport Packaging

Our products are carefully packaged to ensure safe transportation. We use:

- Custom-fitted foam inserts

- Sturdy corrugated boxes

- Vacuum-sealed bags for moisture protection

- Shock-absorbing materials for delicate parts

- Clear labeling and handling instructions

FAQ

Q1: What is the minimum order quantity for the products?

A1: Our minimum order quantity is typically 100 units, but we can accommodate smaller orders for specialized or custom designs.

Q2: Can you provide samples before bulk orders?

A2: Yes, we offer sample production for quality verification. Sample fees may apply but are often credited towards your bulk order.

Q3: What is the lead time for custom products?

A3: Lead times vary based on complexity and quantity. Generally, we can deliver custom orders within 2-4 weeks after design approval.

Q4: Do you offer any warranty on your products?

A4: We provide a 12-month warranty against manufacturing defects for all our standard and custom bearing seats.

Q5: Can your products be used in high-temperature environments?

A5: Yes, we offer specialized bearing seats designed for high-temperature applications up to 300°C. Please consult with our team for specific requirements.

Contact Us

Ready to enhance your machinery with our precision-engineered Mechanical Parts Bearing Seats? Contact our expert team today for personalized solutions and quotations. Email us at service@kaihancnc.com to start your journey towards improved equipment performance and reliability.

Learn about our latest products and discounts through SMS or email