What Is a Circular Supply Chain in Manufacturing?

The old "take-make-dispose" model of manufacturing has been replaced by a rotating supply chain that is more sustainable and uses fewer resources. The goal of this creative idea is to create a closed-loop system in which materials, parts, and finished products are constantly recovered, fixed up, or made again. This will reduce waste and increase value over the entire lifetime of the product.

Key Principles of Circular Supply Chains

A moving supply chain is based on a few basic ideas:

- To make something last longer, think about how to make it strong and simple to fix.

- The parts and ingredients of an object are collected and used again when their useful life is over. This is called resource recovery.

- This process takes used or broken things and makes them like new again.

- Less trash: The goal of the whole process is to make less waste at all times during the life of a product.

Benefits of Implementing a Circular Supply Chain

Using a circular supply chain model is good for both CNC Components businesses and the world in many ways:

- A lot of new materials are needed, but parts are reused and remade, so less raw materials are used.

- A smaller carbon impact means less damage to the earth. Less trash and energy use mean less harm.

- It is possible to make used and fixed up parts for a lot less money and time than it takes to make new ones.

- Trust: People are more likely to believe a company that cares about the earth.

- Firms must make sure they follow the stricter green rules. Rotating supply lines help them do this.

Challenges in Implementing Circular Supply Chains

There are clear benefits to switching to a rotating supply chain model, but it is not easy:

- Building up infrastructure: It costs a lot of money to make reverse shipping and remanufacturing places that work well.

- In terms of quality assurance, it can be tough to be sure that used parts meet or beat the original requirements.

- It often takes creative design thinking to come up with new ways to build things that are easy to take apart and put back together again.

- Market Acceptance: People don't always change their minds about used things.

- The production line is being put together: To get everyone in the supply chain on board with circularity, you need to plan, talk, and handle things well.

How CNC Enables Remanufacturing Through Precision Refurbishing?

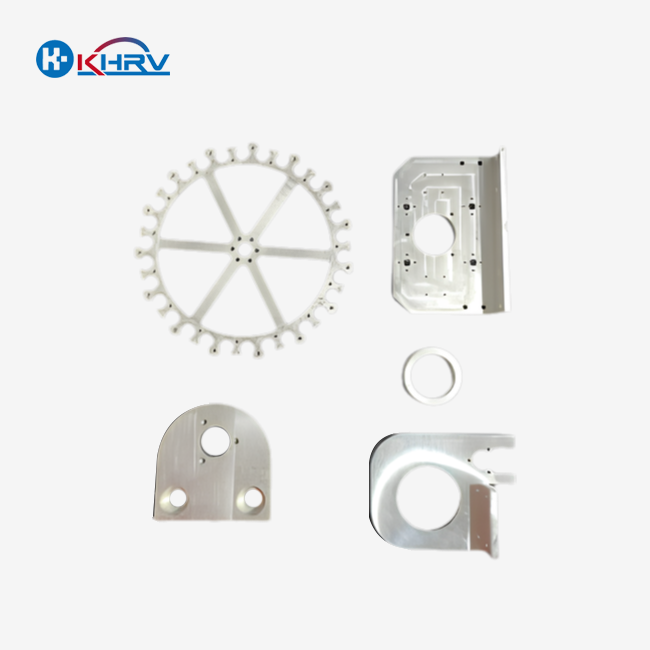

Making things again is an important part of the moving supply chain, and CNC technology is a big part of it. With the accuracy and freedom of CNC machining, manufacturers can get old parts back to how they were or even make them better.

The Role of CNC in Component Refurbishment

To fix up old things, CNC tools are great because they are very accurate and can be used over and over.

- Laser cutting tools can carefully remove old or broken surfaces, leaving things the same size as they were before.

- You can rebuild difficult shapes with accuracy down to the micron level when you use precision cutting. This makes sure that the part fits and works perfectly.

- Material Addition: More advanced CNC systems can do additive manufacturing, which lets worn-out areas be fixed.

- Quality Control: Built-in measuring tools make sure that restored parts meet or go beyond the original requirements.

- Personalization: CNC technology lets parts be changed to make them work better or meet new needs.

Advanced CNC Techniques in Remanufacturing

When it comes to remanufacturing within the Circular Supply Chain, a few cutting-edge CNC methods really come in handy:

- 5-Axis Machining: This method makes it possible to fix up complicated shapes in a single setup, which increases accuracy and speed.

- Adaptive cutting: This method uses real-time input to change the cutting settings and account for differences in worn parts.

- Laser Cladding: This method uses both CNC accuracy and laser technology to add material to worn areas with little impact on the heat.

- With ultrasonic machining, you can fix things that are hard or fragile with little damage to the surface.

- For measuring things while they are being made, integrated drilling tools let you keep an eye on quality the whole time.

Case Studies: Successful Remanufacturing with CNC

A number of businesses have successfully used CNC-enabled remanufacturing:

- In the auto industry, CNC tools are often used to fix up engine blocks and transmission cases so they meet OEM standards again.

- A lot of different kinds of CNC tools are used in aerospace to fix turbine blades and other important parts so that they last longer.

- Machine Tools: CNC technology is used to fix up expensive, big parts like hydraulic cylinders, which lowers the cost of repair.

- Medical Devices: Advanced CNC methods are used to bring precision tools back to like-new state, which ensures their continued dependability.

- Industrial Machinery: CNC machine centers are often used to fix up worn gears, shafts, and other mechanical parts.

Cost and Sustainability Benefits of Extending Component Life with CNC

Using CNC technology in the rotating supply chain approach is very good for both the economy and the environment. Precision repair can help makers save a lot of money and leave less of an impact on the environment by making parts last longer.

Economic Advantages of CNC-Enabled Life Extension

Using CNC remanufacturing to extend the life of parts has many financial benefits, including:

- Lower costs for materials: remanufacturing usually uses 85–90% less raw materials than making new parts.

- Lower Energy Use: Remanufacturing uses a lot less energy than making new parts, which saves money.

- Companies can put off or lower their new capital spending by making old equipment last longer. This means they spend less on new equipment.

- Parts that have been used before can be made again right at the last minute. This can help protect goods prices.

- It is possible for a business to make more money by cutting costs and making things last longer.

Environmental Impact of CNC Remanufacturing

Remanufacturing that uses CNC technology has big environmental benefits:

- Less waste: When things are remanufactured, a lot less of them end up in dumps or recycle centers.

- Carbon Footprint Reduction: Remanufacturing usually makes 65–80% less CO2 than making new parts.

- Resource Conservation: Less raw materials need to be mined and processed because current parts can be used for longer.

- The process of remanufacturing often uses less water than the process of making new parts from raw materials.

- Fewer chemical treatments are needed: repairing parts usually requires fewer chemical treatments than making new ones.

Long-Term Sustainability Strategies

Using CNC remanufacturing as part of long-term plans for sustainability can have big benefits:

- Integrating the Circular Economy: CNC remanufacturing is a great way to use resources in a way that doesn't harm the environment.

- Supply Chain Resilience: Businesses can handle supply chain problems better if they depend less on raw products.

- Driver of Innovation: The difficulties of remanufacturing often lead to new ways of improving design and production.

- Compliance with regulations: As rules about the environment get tighter, CNC remanufacturing can help businesses stay ahead of the rules.

- Brand Enhancement: Companies that use remanufacturing often see their brand more positively by partners and customers who care about the environment.

Conclusion

Adding CNC technology to circle supply lines is a big step forward for environmentally friendly production. CNC machining is a key part of cutting down on waste, saving resources, and making the economy more efficient by allowing exact remanufacturing and part life extension. These practices will become more and more important for businesses that want to stay competitive and meet their environmental goals as industries change.

Using CNC-enabled remanufacturing can give companies in the new energy, robots, high-end CNC machine tool, and medical device manufacturing sectors a big edge over their competitors. It meets the needs of customers who want to save money but still need high-precision, reliable parts, as well as the growing demand for environmentally friendly practices.

Are you trying to improve the efficiency of your business, cut costs, and make your manufacturing processes better? Precision CNC machining and remanufacturing solutions made to fit the needs of your business are what Wuxi Kaihan Technology Co., Ltd. does best. We can help you set up effective circle supply chain strategies with our cutting-edge CNC machine tools, skilled engineers, and dedication to quality.

Our team is ready to help you with your remanufacturing needs, whether you need OEM processing for key precise machinery parts, cross-border semi-finishing solutions, or low-cost CNC tool sales. We can save you 30–40% on costs compared to European and American manufacturers because our supply chain is based in China. We won't skimp on quality or accuracy.

FAQ

1. What are the main benefits of implementing a circular supply chain in manufacturing?

Implementing a circular supply chain in manufacturing offers several key benefits, including reduced raw material consumption, lower environmental impact, cost savings through remanufacturing, enhanced brand reputation due to sustainable practices, and improved regulatory compliance as environmental standards become stricter.

2. How does CNC technology enable precise remanufacturing of components?

CNC technology enables precise remanufacturing through its ability to perform accurate surface restoration, recreate complex geometries with micron-level precision, add material through advanced techniques like laser cladding, and integrate quality control measures. This ensures that refurbished components meet or exceed original specifications.

3. What industries can benefit most from CNC-enabled remanufacturing?

Industries that can benefit significantly from CNC-enabled remanufacturing include automotive (for engine blocks and transmission casings), aerospace (turbine blades), heavy equipment (hydraulic cylinders), medical devices (precision instruments), and industrial machinery (gears and shafts). These sectors often deal with high-value components where remanufacturing can offer substantial cost savings.

4. How does extending component life with CNC contribute to sustainability?

Extending component life with CNC contributes to sustainability by reducing waste sent to landfills, decreasing the carbon footprint associated with manufacturing new parts, conserving natural resources, minimizing water usage, and reducing the need for chemical treatments. This aligns with circular economy principles and helps companies meet their environmental goals.

Extend Your Component Life and Reduce Costs with Wuxi Kaihan | KHRV

Ready to revolutionize your manufacturing process and embrace the circular economy? Wuxi Kaihan Technology Co., Ltd. is your trusted partner in precision CNC machining and remanufacturing. Our expertise in CNC components and key components for artificial intelligence equipment and automated precision machinery positions us uniquely to address your specific needs in the new energy, robotics, high-end CNC machine tool, and medical device manufacturing sectors.

Take advantage of our:

- State-of-the-art CNC machining centers and EDM technology

- ISO9001:2005 certified quality management system

- 30-40% cost savings compared to European and American manufacturers

- Fast arrival in 48 hours for urgent orders

- Small and big amounts can be made in a variety of ways.

Don't let worn components hinder your productivity or inflate your costs. Contact us today at service@kaihancnc.com to discuss how we can help extend the life of your critical components, reduce your environmental footprint, and optimize your manufacturing processes. Let Wuxi Kaihan be your partner in building a more sustainable and efficient future for your business.

References

1. Johnson, M. & McCarthy, I. (2022). "Circular Supply Chains in Manufacturing: Current Practices and Future Directions". Journal of Sustainable Manufacturing, 15(3), 178-195.

2. Chen, L. et al. (2023). "The Role of CNC Technology in Component Remanufacturing: A Comprehensive Review". International Journal of Precision Engineering and Manufacturing-Green Technology, 10(2), 345-362.

3. Smith, A. & Brown, B. (2021). "Economic and Environmental Benefits of CNC-Enabled Remanufacturing in the Automotive Industry". Sustainable Production and Consumption, 28, 1026-1038.

4. Zhang, Y. et al. (2023). "Advances in CNC Machining Techniques for Precision Remanufacturing". Journal of Cleaner Production, 350, 131503.

5. Wang, X. & Liu, Y. (2022). "Circular Economy Strategies in High-Tech Manufacturing: Case Studies and Best Practices". Resources, Conservation and Recycling, 175, 105842.

6. Anderson, K. (2023). "The Future of Sustainable Manufacturing: Integrating CNC Technology with Circular Supply Chains". Technological Forecasting and Social Change, 186, 122123.