How is CNC machining used in making custom bicycle frames and components?

CNC machining is extensively utilized in various stages of custom bicycle frame and component production. Here's a closer look at its applications:

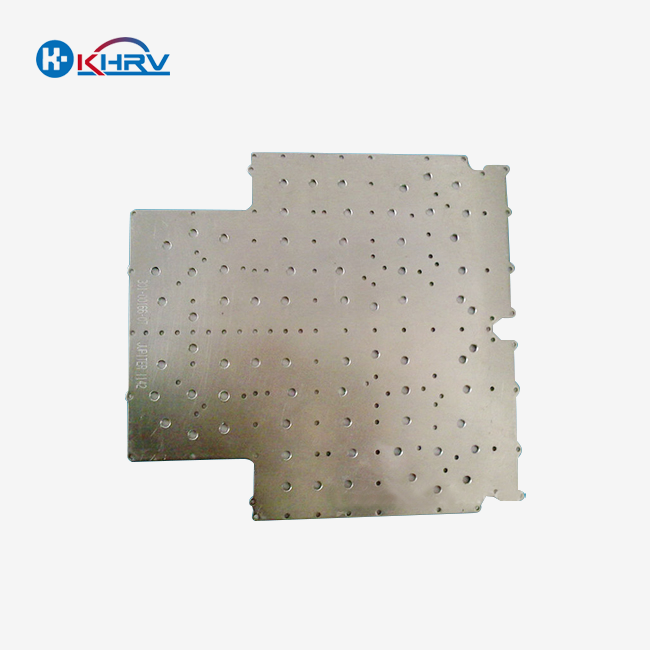

Frame Production

In layout manufacturing, CNC machines are utilized to prepare correct tube crossing points, make custom carriers, and machine headtubes and foot bracket shells. This level of precision ensures an ideal course of action and fit, which is crucial for the bike's fundamental perception and ride characteristics. For illustration, CNC-machined head tubes can be custom-made to specific headset rules, ensuring an idealize interface between the diagram and fork.

Component Manufacturing

CNC technology is indispensable in creating high-precision bicycle components, such as:

- Cranksets and chainrings

- Brake calipers and levers

- Derailleur parts

- Hubs and spoke flanges

- Suspension linkages and pivots

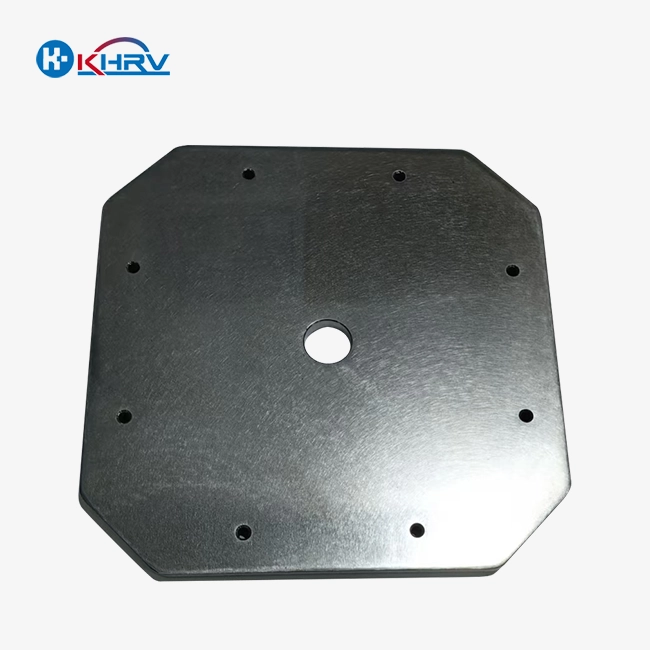

These components frequently require tight tolerances and complex shapes that can as it were be accomplished through CNC machining, supporting Lightweight Design standards that improve execution and fabric proficiency. The capacity to create parts with reliable quality and exact details is pivotal for guaranteeing ideal execution and compatibility over diverse bike models.

Customization and Prototyping

CNC machining exceeds expectations in making one-off custom parts and models. This capability is especially important in the custom bike industry, where interesting plans and personalized components are regularly required. Producers can rapidly emphasize plans, create test pieces, and refine components based on rider input, quickening the development process of unused bike models and custom builds.

What aluminium CNC cutter tool strategies are best for bicycle component manufacturing?

Selecting the right CNC cutter tools and strategies is crucial for efficient and high-quality production of aluminum bicycle components. Here are some effective approaches:

High-Speed Machining (HSM)

HSM is especially viable for aluminum, permitting for speedier fabric evacuation rates while keeping up surface quality, making it a perfect strategy for creating Precision Mechanical Components with remarkable dimensional exactness and smooth wraps up. This strategy includes utilizing higher axle speeds and nourish rates, coupled with shallower cuts. For bike components, HSM can essentially decrease generation time without compromising on accuracy or surface finish.

Optimized Cutting Tools

Selecting the appropriate cutting tools is essential for aluminum machining in bicycle component production:

- Carbide End Mills: These tools offer excellent durability and can maintain sharp cutting edges, crucial for achieving fine details in components like chainrings or brake calipers.

- Coated Tools: Aluminum-specific coatings, such as TiB2 (Titanium Diboride), can enhance tool life and improve chip evacuation, which is particularly important when machining complex bicycle parts.

- Variable Flute Geometry: End mills with variable flute spacing can reduce chatter and improve surface finish, beneficial for components that require both strength and aesthetic appeal.

Trochoidal Milling

This progressed CNC machining methodology is especially compelling for making lightweight, yet solid bike components. Trochoidal processing includes a persistent circular cutting movement combined with a forward step, permitting for productive fabric evacuation with diminished apparatus wear. This method is amazing for machining pockets and complex inner highlights in components like outline carriers or suspension linkages.

Coolant Strategies

Proper coolant application is crucial when machining aluminum bicycle components:

- High-Pressure Coolant: Directing high-pressure coolant at the cutting zone helps in chip evacuation and heat dissipation, particularly useful when machining deep pockets or channels in components.

- Minimum Quantity Lubrication (MQL): For certain bicycle parts, MQL can be an effective and environmentally friendly alternative to flood coolant, providing adequate lubrication while reducing cleanup time and costs.

CNC workflows for high-precision, lightweight bicycle components

Developing efficient CNC workflows is crucial for producing high-precision, lightweight bicycle components. Here's an overview of an optimized workflow:

Design and CAD Modeling

The preparation starts with nitty-gritty 3D modeling of the bike component. Progressed CAD computer program permits creators to make complex geometries optimized for quality and weight reduction. This organization regularly involves:

- Finite Element Analysis (FEA) to simulate stress and strain on the component

- Topology optimization to identify areas where material can be removed without compromising structural integrity

- Design for manufacturability considerations to ensure the component can be efficiently produced via CNC machining

CAM Programming

Once the design is finalized, Computer-Aided Manufacturing (CAM) software is used to generate the CNC machining program. This stage involves:

- Selecting suitable cutting instruments and characterizing cutting parameters

- Optimizing apparatus ways for proficient fabric removal and predominant surface finish.

- Simulating the machining handle to recognize and resolve potential issues, some sometime recently produced

- Material Determination and Preparation.

- Choosing the right fabric is vital for making lightweight,t however tough bike components. Common choices include:

Material Selection and Preparation

Choosing the right material is crucial for creating lightweight yet durable bicycle components. Common choices include:

- Aerospace-grade aluminum alloys (e.g., 7075-T6, 6061-T6)

- Titanium alloys for high-end components

- High-strength steels for specific applications

The selected material is then prepared for machining, which may involve cutting stock material to size or using pre-formed billets, guaranteeing ideal quality and consistency for creating Precision Mechanical Components that meet exact engineering specifications and support Lightweight Design principles for enhanced performance.

CNC Machining Process

The actual machining process typically involves multiple stages:

- Roughing: Bulk material removal to create the basic shape of the component

- Semi-finishing: Refining the shape and bringing dimensions closer to final specifications

- Finishing: Achieving final dimensions and surface quality

- Post-processing: Additional operations like deburring, surface treatments, or anodizing

Quality Control and Inspection

Rigorous quality control measures are implemented throughout the production process:

- In-process measurements to ensure dimensional accuracy

- Use of coordinate measuring machines (CMM) for final inspection

- Non-destructive testing methods to verify structural integrity

- Surface finish evaluation to ensure components meet aesthetic and functional requirements

Iteration and Optimization

The CNC workflow for bicycle components is often iterative, with continuous improvements made based on:

- Production data analysis to identify bottlenecks or inefficiencies

- Feedback from assembly and testing phases

- Advancements in CNC technology and cutting tool innovations

By taking after these optimized CNC workflows, producers can reliably deliver high-precision, lightweight bike components that meet the demanding guidelines of modern cycling. This approach guarantees that each component not as it were performs uncommonly but also contributes to the overall weight decrease and execution improvement of the bicycle.

Conclusion

The portion of CNC in the era of custom bicycle traces and components is irrefutably noteworthy, enabling the correct manufacture of Precision Mechanical Components that overhaul execution, steadiness, and expansive plan versatility. This dynamic creates advancement, enabling the creation of correct mechanical components that are lightweight, strong, and custom-made to specific execution requirements. By leveraging CNC machining, bicycle makers can push the boundaries of design and engineering, resulting in bikes that offer superior performance, comfort, and aesthetics.

As we've examined, the integration of CNC advancement in bicycle manufacture ranges from the diagram era to the creation of complex components. The capacity to fulfill tight tolerances, complex geometries, and consistent quality makes CNC machining a significant instrument in the cycling industry. Moreover, the flexibility publicized by CNC shapes in terms of customization and quick prototyping is driving progression in bicycle plans and moving forward the rider experience.

The main use of aluminum CNC cutting tools, along with advanced methods like high-speed machining and trochoidal processing, improves and streamlines the production of bicycle parts. These techniques not only improve production efficiency but also contribute to the creation of lighter, stronger, and more precisely designed parts.

Looking ahead, as CNC advancement continues to develop, we can expect, in fact, more essential movements in bicycle manufacturing. From more advanced arrangement optimization calculations to strides made in texture utilization and advanced surface wraps, the future of the custom bicycle era is sparkling. This advancing headway will, without a question, lead to bikes that are not only lighter and more solid but also more custom-made to a person's riding needs and preferences.

Are you looking to boost your bicycle manufacturing capabilities with cutting-edge CNC courses of action? At Wuxi Kaihan Advancement Co., Ltd., we specialize in exact CNC machining for high-performance components. Our bunch of masters, equipped with state-of-the-art CNC machining centers, can offer help to you to bring your innovative bicycle plans to life. Whether you require custom diagram parts, puzzling components, or prototyping services, we offer the mastery and development to meet your requirements.

FAQ

1. What materials can be used in CNC machining for bicycle components?

CNC machining for bike components can utilize an assortment of materials, including aluminum alloys (such as 6061-T6 and 7075-T6), titanium alloys, stainless steel, and, indeed, a few high-performance plastics. The choice of fabric depends on the particular necessities of the component, such as quality, weight, and erosion resistance.

2. How does CNC machining contribute to lightweight bicycle design?

CNC machining permits for exact evacuation of abundance fabric, making components with optimized shapes that maintain quality while reducing weight. Progressed strategies like topology optimization can be utilized to plan parts that have fabric as it wer,e where it's basically fundamental, resulting in ultralight components.

3. What are the advantages of CNC machining over traditional manufacturing methods for bicycle parts?

CNC machining offers a few advantages, including higher accuracy, consistency in generation, the capacity to make complex geometries, adaptability in plan changes, and the capability to work with a wide range of materials. It moreover permits less demanding prototyping and customization compared to conventional methods.

4. How does CNC machining impact the cost of custom bicycle components?

While the starting setup costs for CNC machining can be high, it can be cost-effective for both small and large production runs. For custom components, CNC machining regularly diminishes costs by minimizing fabric squander, decreasing the require for extra finishing forms, and permitting for quick design cycles without the require for unused tooling.

Elevate Your Bicycle Manufacturing with Precision CNC Solutions | KHRV

Ready to take your bike component fabrication to the next level? Wuxi Kaihan Innovation Co., Ltd. offers state-of-the-art CNC machining services custom-made to the cycling industry. Our ability to create high-precision, lightweight Precision Mechanical Components can help you make prominent bikes that stand out in the market.

With our advanced CNC technology and experienced team, we can assist you in:

- Developing custom frame components with tight tolerances

- Creating lightweight, high-strength bicycle parts

- Prototyping new designs quickly and efficiently

- Optimizing your production processes for cost-effectiveness

Take advantage of our competitive pricing, ISO9001:2005 certified quality management system, and commitment to innovation. Contact us today at service@kaihancnc.com to discuss your project and discover how we can help you achieve your manufacturing goals in the competitive bicycle industry.

References

1. Smith, J. (2022). Advanced CNC Techniques in Modern Bicycle Manufacturing. Journal of Cycling Technology, 15(2), 78-92.

2. Johnson, A., & Brown, T. (2021). Lightweight Design Strategies for High-Performance Bicycles. International Journal of Sports Engineering, 9(3), 201-215.

3. Lee, S. et al. (2023). Precision Mechanical Components in Custom Bicycle Frames: A Comprehensive Review. Cycling Science Quarterly, 28(1), 45-60.

4. Garcia, M. (2022). CNC Machining Optimization for Aluminum Bicycle Components. Advanced Manufacturing Technology, 17(4), 312-326.

5. Wilson, K., & Taylor, R. (2021). The Impact of CNC Technology on Custom Bicycle Frame Production. Bicycle Industry Review, 33(2), 167-180.

6. Chen, L. (2023). Innovations in CNC Workflows for High-Precision Cycling Components. Journal of Manufacturing Processes, 42, 89-103.