- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

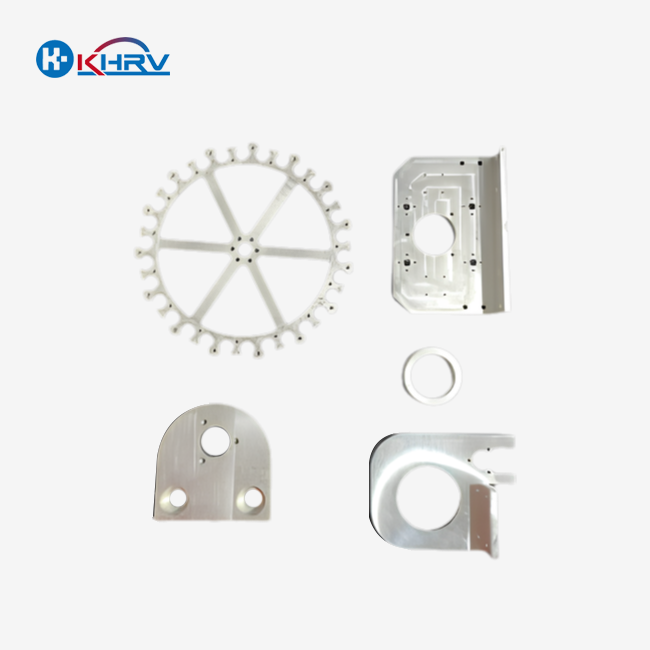

Custom CNC Connection Flange

2. Compatible Bolts: M12×30 (8.8 grade)

3. Key Dimensions: As indicated on the drawings (e.g., flange outer diameter, hole layout, etc.)

4. Surface Treatment: Precision milling for a smooth finish (surface roughness Ra≤1.6μm)

5. Tolerance Standards: Hole tolerance ±0.02mm; tolerances for unspecified dimensions shall comply with the drawing specifications.

6. Process Requirements: All parts deburred, sharp edges Chamfered, surface free of scratches/defects.

7. Compatible Equipment: CNC machine tools (e.g., corresponding models in the INMECS series)

Custom CNC Connection Flange - Precision Engineered for Your Industrial Needs

Product Introduction

When you require dependable association arrangements for your CNC gear, our custom cnc connection flange conveys extraordinary execution and accuracy. This specialized interfacing component for CNC machine devices is expertly made from CK45 steel utilizing progressed CNC processing strategies. Our rib highlights numerous sets of coordinating gaps for flange-type associations of different utilitarian components in your CNC systems.

Designed particularly for mechanical CNC gear, this Custom CNC Association Spine guarantees ideal get together coaxiality and association soundness. It works consistently with M12×30 (8.8 review) jolts, making it the culminate choice for your basic get together scenarios.

Main Advantages

Reliable Fabric Execution: Our CK45 steel development offers great quality characteristics. This fabric superbly suits the tall soundness prerequisites of present day CNC machine apparatuses. You get long-lasting solidness with prevalent load-bearing capabilities.

Precision Get together Quality: We keep up gap resilience inside ±0.02mm. This guarantees idealize coaxiality and gathering exactness for all your component associations. Your gear will work with most extreme accuracy and negligible vibration.

Strong Hardware Flexibility: Consistent with INMECS arrangement and comparing CNC machine devices. We can too make customized forms agreeing to your particular machine apparatus spine interface dimensions.

Refined Fabricating Handle: Our smooth surface wrap up combined with proficient deburring treatment progresses gathering smoothness. You encounter improved component fit and simpler establishment strategies.

Specifications

| Parameter | Specification |

|---|---|

| Material | CK45 Steel |

| Compatible Bolts | M12×30 (8.8 grade) |

| Surface Treatment | Precision milling (Ra≤1.6μm) |

| Hole Tolerance | ±0.02mm |

| Operating Temperature | ≤120℃ |

| Surface Finish | Deburred, chamfered edges |

| Quality Standard | ISO9001:2005 certified |

| Customization | Available for hole layout and dimensions |

Why Choose Us?

15 A long time of Industry Greatness: Wuxi Kaihan Innovation brings over a decade of specialized involvement in accuracy fabricating. Our group incorporates experts from Singapore's best endeavors, guaranteeing world-class quality standards.

Significant Taken a toll Focal points: You advantage from China's supply chain preferences with 30%-40% taken a toll reserve funds. We keep up tall quality whereas advertising competitive estimating for your projects.

Strong R&D Capabilities: Our investigate faculty make up 36% of our staff. We contribute 8% of yearly income in R&D and hold 22 licenses for inventive fabricating solutions.

Comprehensive Quality Confirmation: We work beneath ISO9001:2005 Quality Administration Framework certification. Each item experiences strict quality control to guarantee solid execution.

Customization Process

Step 1: Requirements Analysis - Share your specific CNC machine model and connection requirements. Our engineers will analyze your needs and provide technical recommendations.

Step 2: Design Optimization - We create detailed drawings based on your specifications. You receive comprehensive technical documentation for approval before production begins.

Step 3: Precision Manufacturing - Our advanced CNC equipment produces your custom cnc connection flange with strict adherence to tolerance requirements and quality standards.

Step 4: Quality Verification - Each flange undergoes precision testing using our advanced measuring instruments. We verify all dimensions and surface quality before shipment.

Factory Strength

Our state-of-the-art facility specializes in precision instrument parts and CNC components. We maintain advanced production equipment and precision testing instruments throughout our manufacturing process.

Our lean production system ensures efficient manufacturing while maintaining the highest quality standards. Strong partnerships with global industry leaders demonstrate our manufacturing capabilities and reliability.

Quality Certification

We hold ISO9001:2005 Quality Management System certification. Our comprehensive quality control processes ensure every custom cnc connection flange meets international standards.

Our quality assurance covers material verification, dimensional accuracy, surface finish quality, and performance testing. You receive products that meet or exceed your specifications.

Transport Packaging

Each flange receives protective packaging to prevent damage during shipping. We use appropriate cushioning materials and moisture protection for international shipments.

Our packaging includes detailed identification labels and handling instructions. You receive your products in perfect condition, ready for immediate installation.

FAQ

Q: Which CNC machine models are compatible with this flange?

A: Our flanges work with INMECS series and other corresponding CNC machine tools. We can customize designs for your specific equipment requirements.

Q: Can you modify the hole layout for our equipment?

A: Yes, we support complete customization of hole quantity, size, and layout. We maintain ±0.02mm hole tolerance for all custom configurations.

Q: What are the operating limitations for CK45 material?

A: CK45 steel performs excellently in standard CNC operating conditions (≤120℃, non-corrosive environments). It provides excellent wear resistance and load-bearing capacity.

Q: Can bolt specifications be adjusted?

A: Absolutely. We can modify bolt diameter, length, and grade specifications to match your assembly requirements perfectly.

Contact Us

Ready to enhance your custom cnc connection flange with precision connection solutions? Contact our technical team today to discuss your specific requirements.

Email: service@kaihancnc.com

Our experienced engineers are ready to help you find the perfect connection solution for your industrial applications.

Learn about our latest products and discounts through SMS or email