- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

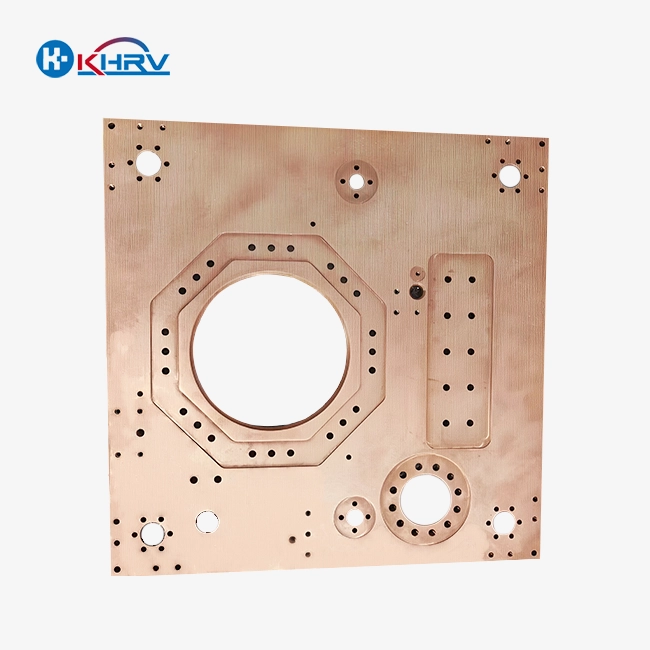

Servo motor valve

Valve orifice tolerance: H7

Roughness: Ra ≤ 0.8 μm

Testing: 100% 1.5x pressure air tightness test

Sealing: Supports O-rings, Glyd rings, and other solutions

Features: Zero leakage, high response, compact

Support sample service

Support OEM,ODM customization

Delivery time: 10-20 working days

Certification: ISO9001:2015 , Complies with EU RoHS standards

Servo Motor Valve - High-Performance Precision Control Solution

Looking for dependable liquid control in your computerized frameworks? Our servo motor valve combines cutting-edge servo engine innovation with exactness valve building to provide remarkable execution. This coordinates arrangement gives exact stream control, fast reaction times, and zero spillage operation. Whether you require pressure driven or pneumatic control, our servo engine valve offers the unwavering quality your applications request. Built with premium 6061-T6 aluminum and including progressed fixing innovation, this valve conveys steady comes about over requesting mechanical environments.

Main Advantages

Integrated Design Excellence

Our compact structure dispenses with superfluous association focuses, lessening potential spillage regions whereas moving forward in general framework unwavering quality. This streamlined approach spares profitable establishment space.

Superior Flow Optimization

Smooth inside stream channels minimize weight misfortune and maximize reaction speed. You'll encounter speedier framework responses and moved forward vitality proficiency in your operations.

Advanced Materials Engineering

The 6061-T6 aluminum development gives amazing strength-to-weight proportion with extraordinary warm dissemination properties. This combination guarantees long-lasting execution indeed in challenging conditions.

Zero Leakage Performance

Multiple fixing alternatives counting O-rings and Glyd rings ensure leak-free operation. Your frameworks keep up weight keenness all through expanded operation cycles.

Specifications

| Parameter | Specification |

|---|---|

| Material | 6061-T6 Aluminum |

| Valve Orifice Tolerance | H7 |

| Surface Roughness | Ra ≤ 0.8 μm |

| Maximum Working Pressure | ≤10MPa (Standard), ≤16MPa (Custom) |

| Quality Testing | 100% 1.5x Pressure Air Tightness Test |

| Sealing Options | O-rings, Glyd rings, Custom Solutions |

| Key Features | Zero Leakage, High Response, Compact Design |

| Delivery Time | 10-20 Working Days |

| Certification | ISO9001:2015, EU RoHS Compliant |

Why Choose Us?

15 Years of Proven Excellence

Since 2011, Wuxi Kaihan Innovation has conveyed accuracy components to worldwide industry pioneers. Our experienced group brings Singapore-standard skill to each project.

Cost-Effective Solutions

Benefit from China's supply chain focal points with 30%-40% taken a toll reserve funds without compromising quality. You get premium execution at competitive prices.

Innovation-Driven Approach

With 36% of our group devoted to investigate and 8% of income contributed in R&D, we hold 22 licenses. This commitment guarantees you get the most recent innovative advances.

Comprehensive Quality Systems

Our ISO9001:2015 certification and strict quality control forms ensure reliable item execution. Each servo motor valve experiences thorough testing some time recently delivery.

Customization Process

Step 1: Consultation

Share your specific requirements with our technical team. We'll analyze your application needs and recommend optimal configurations.

Step 2: Design & Engineering

Our experts create detailed designs tailored to your specifications. You'll receive technical drawings for approval before production begins.

Step 3: Manufacturing

Using advanced CNC equipment and precision testing instruments, we manufacture your custom components to exact specifications.

Step 4: Quality Verification

Each product undergoes comprehensive testing including pressure testing and dimensional verification to ensure perfect performance.

Factory Strength

Our state-of-the-art office highlights progressed CNC gear and exactness estimation instruments. The incline generation framework empowers proficient fabricating whereas keeping up strict quality standards.

Professional professionals with broad industry involvement handle each generation arrange. This skill guarantees reliable quality over all item batches.

Our comprehensive capabilities cover plan, fabricating, and testing. This integration gives way better quality control and speedier conveyance times for your ventures.

Quality Certification

- ISO9001:2015 Quality Management System

- EU RoHS Compliance

- Complete traceability documentation

- 100% pressure testing verification

Transport Packaging

Protective packaging ensures your products arrive in perfect condition. We use appropriate cushioning materials and sturdy containers designed for international shipping.

Each package includes detailed documentation and handling instructions. This comprehensive approach protects your investment during transit.

FAQ

What's the maximum working pressure capacity?

Standard models handle up to 10MPa. We also manufacture high-pressure versions reaching 16MPa for specialized applications.

Do you provide custom sealing solutions?

Yes! We offer fluororubber seals for oil resistance (-20℃ to 200℃) and silicone seals for high-temperature applications (-60℃ to 300℃).

What's your delivery timeframe?

Standard delivery takes 10-20 working days. Custom orders may require additional time depending on complexity.

Do you offer samples?

Absolutely! Sample service is available to help you evaluate our products before placing larger orders.

Contact Us

Ready to enhance your fluid control systems? Our servo motor valve's technical team is standing by to discuss your specific requirements.

Email: service@kaihancnc.com

Contact us today for detailed specifications, custom quotes, or technical consultation. We're committed to providing solutions that exceed your expectations.

Learn about our latest products and discounts through SMS or email