- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

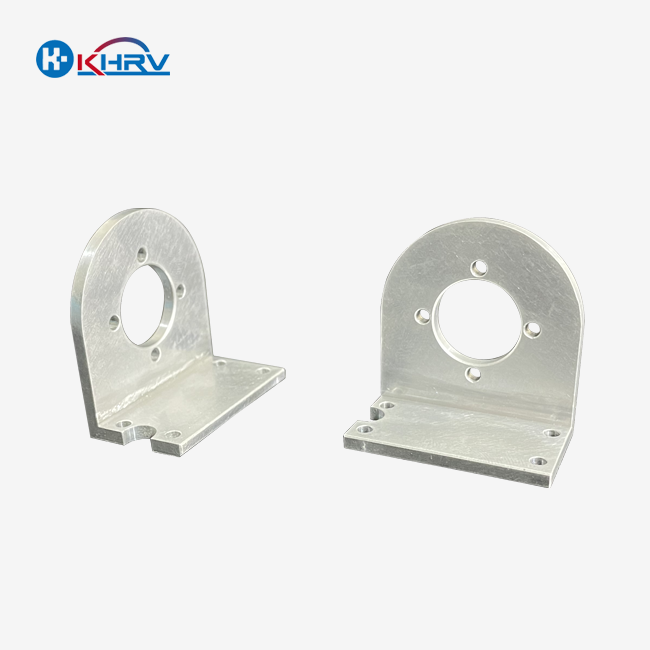

Linear Guide Mounting Base

Flatness: ≤ 0.02mm/1000mm

Parallelism: ≤ 0.01mm/1000mm

Process: Precision milling/scraping

Compatibility: Supports customized mainstream brand guide rail interfaces

Features: High rigidity, high stability

Support sample service

Support OEM,ODM customization

Delivery time: 10-20 working days

Certification: ISO9001:2015 , Complies with EU RoHS standards

Linear Guide Mounting Base - Precision Engineered for Superior Performance

Product Introduction

When you require dependable situating precision for your mechanization frameworks, our linear guide mounting base conveys extraordinary exactness and steadiness. Fabricated from high-grade 6061-T651 aluminum amalgam, this mounting base gives the idealize establishment for your straight movement applications. Our Straight Direct Mounting Base highlights precision-milled surfaces with levelness resistance of ≤0.02mm/1000mm and parallelism of ≤0.01mm/1000mm. Each base experiences strict quality control forms to guarantee steady execution. Consistent with standard direct rail brands, our mounting bases bolster both standard and customized arrangements to meet your particular requirements.

Main Advantages

Precise Reference Foundation

Professional mounting groove plan guarantees ideal straightness and parallelism for direct rail establishment. This exactness disposes of arrangement issues and diminishes setup time.

Superior Rigidity

Robust base structure minimizes misshapening beneath overwhelming loads. The aluminum amalgam development gives great strength-to-weight proportion for requesting applications.

Extended Service Life

Precision-fit plan decreases wear between components. This cautious building expands the life expectancy of your whole movement system.

Vibration Aging Treatment

Advanced CNC processing also vibration maturing prepare dispenses with over 90% of inside preparing push. This guarantees long-term dimensional solidness.

Specifications

| Parameter | Specification |

|---|---|

| Material | 6061-T651 Aluminum Alloy |

| Flatness | ≤ 0.02mm/1000mm |

| Parallelism | ≤ 0.01mm/1000mm |

| Processing Method | Precision Milling/Scraping |

| Mounting Groove Tolerance | H7 |

| Straightness | ≤ 0.005mm/100mm |

| Stress Relief | >90% Internal Stress Eliminated |

| Compatibility | THK, HIWIN, IKO, Custom Brands |

| Lead Time | 10-20 Working Days |

| Certifications | ISO9001:2015, EU RoHS Compliant |

Why Choose Us?

15 Years of Manufacturing Excellence

Since 2011, we've specialized in precision component manufacturing. Our experienced team includes professionals from Singapore's leading enterprises.

Cost-Effective Solutions

Benefit from China's supply chain advantages with 30-40% cost savings without compromising quality standards.

Advanced Quality Systems

ISO9001:2015 certified facilities ensure consistent product quality. Every mounting base undergoes rigorous testing before shipment.

Technical Innovation

With 22 patents and 8% annual revenue invested in R&D, we continuously improve our linear guide mounting bases and processes.

Customization Process

Step 1: Requirements Analysis

Share your guide rail specifications and application details with our engineering team.

Step 2: Design Consultation

Our experts review your needs and propose optimal mounting base configurations.

Step 3: Sample Production

We manufacture samples for your testing and approval before full production begins.

Step 4: Quality Verification

Each custom order undergoes comprehensive quality checks to ensure specifications are met.

Step 5: Delivery

Secure packaging and reliable shipping ensure your products arrive in perfect condition.

Factory Strength

Our state-of-the-art office highlights progressed CNC machining centers and exactness testing hardware. Inquire about faculty contain 36% of our workforce, guaranteeing ceaseless development. We keep up incline generation frameworks that empower adaptable fabricating whereas assembly strict quality guidelines. Key organizations with worldwide industry pioneers approve our fabricating capabilities and specialized expertise.

Quality Certification

All items comply with ISO9001:2015 quality administration guidelines. Our fabricating forms meet EU RoHS natural prerequisites. Comprehensive quality control frameworks screen each generation arrange. Customary reviews and nonstop enhancement programs keep up certification compliance.

Transport Packaging

Products are carefully bundled utilizing defensive materials to anticipate harm amid shipping. Anti-static bundling secures touchy surfaces from defilement. Nitty gritty labeling guarantees appropriate taking care of all through the coordinations chain. We work with solid shipping accomplices to ensure secure conveyance around the world.

FAQ

Q: What guide rail brands are compatible with your mounting bases?

A: Our bases work with THK (HSR series), HIWIN (EG series), IKO (LWL series), and other mainstream brands. Custom interfaces available for specific requirements.

Q: How do you ensure dimensional stability over time?

A: Vibration aging treatment eliminates processing stress, maintaining form tolerance stability with flatness change ≤0.002mm/year.

Q: Can you provide samples before full orders?

A: Yes, we offer sample services to verify compatibility and quality before production orders.

Q: What's your typical delivery timeframe?

A: Standard delivery is 10-20 working days, depending on order quantity and customization requirements.

Contact Us

Ready to enhance your automation systems with our precision linear guide mounting base? Our technical team is ready to discuss your specific requirements and provide expert recommendations.

Email: service@kaihancnc.com

Contact us today for detailed quotations, technical specifications, or to request samples. We're committed to delivering the precision components that drive your success.

Learn about our latest products and discounts through SMS or email