- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Automotive uses for High Precision CNC Milling Parts

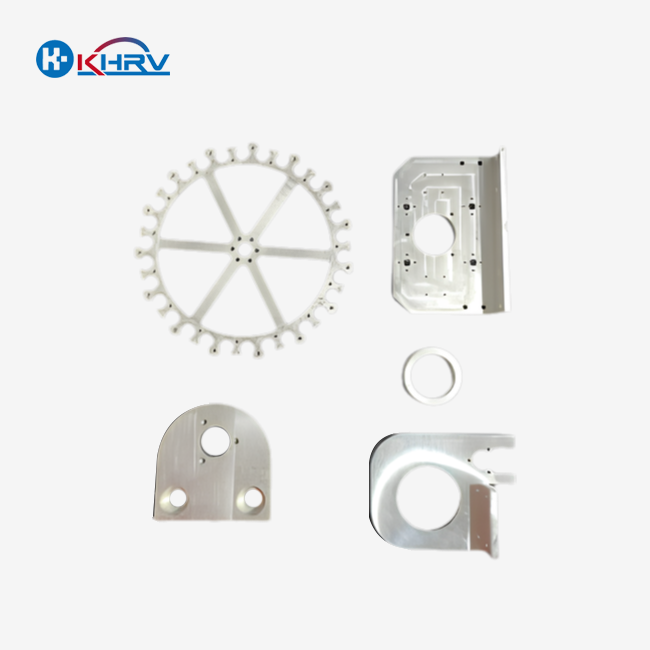

To meet the strict requirements of modern car manufacturing, the automotive industry relies heavily on high precision CNC milling part. Dimensional accuracy and surface finish quality have a direct effect on performance, safety, and dependability because these parts are so important in engine systems, transmission assemblies, brake mechanisms, and electronic control units. Manufacturers can get limits of within ±0.001 inches with high precision CNC milling parts, and the quality stays the same even during high-volume production runs. These precisely machined parts, like aluminum engine blocks and steel transmission gears, are the backbone of modern automobile engineering. They help with everything from making cars more fuel-efficient to making driver assistance systems more advanced.

Engine and Powertrain Applications

Engine Block and Cylinder Head Components

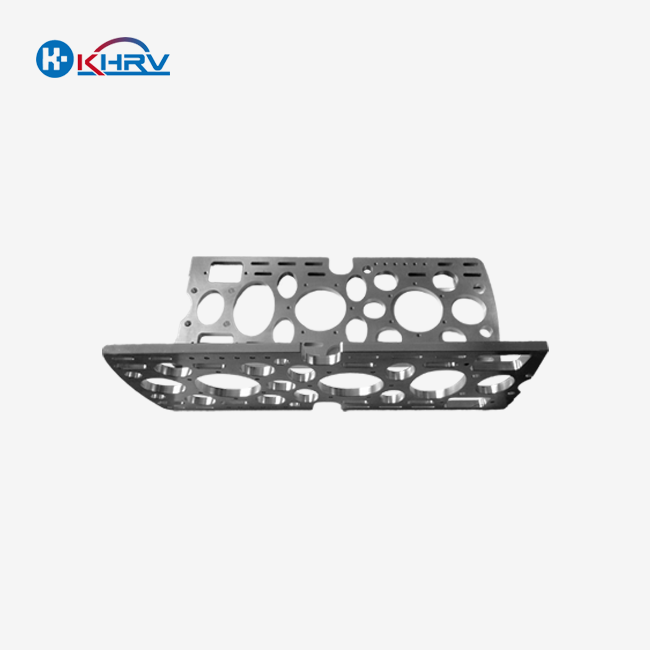

High precision CNC milling parts are essential for making engine blocks and cylinder heads, and the accuracy of the dimensions has a direct effect on how well the engine burns fuel and how well it runs. Advanced CNC milling methods are needed to make modern car engines with complex internal geometries, exact bore measurements, and intricate cooling passages. Aluminum alloys and steel are often used in these parts, which are machined on multiple axes to make valve seats, combustion chambers, and water jacket channels with a very smooth surface finish. The manufacturing methods that are ISO 9001:2015 certified make sure that every high precision CNC milling part meets strict automotive quality standards. Lead times of 10 to 20 working days support just-in-time production schedules. Advanced EDM and grinding techniques improve the quality of parts even more, especially on sealing surfaces and bearing journals that are very important.

Transmission and Drivetrain Components

Transmission systems demand high precision CNC milling parts for gear housings, shift forks, and synchronizer rings where precise tooth profiles and bearing surfaces are essential for smooth operation and longevity. These components often require multi-material processing capabilities, combining steel gear elements with aluminum or brass housings through specialized CNC machining techniques. The precision milling operations create complex internal geometries for hydraulic circuits, precise bearing bores, and intricate shift mechanism components that must operate flawlessly under extreme loads and temperatures. High precision CNC milling parts in transmission applications benefit from advanced plating and anodizing processes that enhance wear resistance and corrosion protection, extending component service life and reducing maintenance requirements throughout the vehicle's operational lifetime.

Fuel System and Injection Components

Modern fuel injection systems rely on high precision CNC milling parts for fuel rail assemblies, injector bodies, and high-pressure pump components where dimensional accuracy affects fuel metering precision and emissions performance. These components typically utilize stainless steel and specialized alloys that resist corrosion while maintaining dimensional stability under varying temperature and pressure conditions. The manufacturing process involves precision boring, surface grinding, and specialized surface treatments to achieve the smooth internal passages and precise orifice dimensions required for optimal fuel atomization. High precision CNC milling parts in fuel systems must meet strict RoHS compliance requirements while delivering consistent performance across millions of injection cycles, making quality control and material traceability essential aspects of the manufacturing process.

Chassis and Safety System Components

Brake System Components

Brake systems represent one of the most critical applications for high precision CNC milling parts in automotive manufacturing, where component accuracy directly impacts vehicle safety and stopping performance. Brake calipers, master cylinders, and ABS valve blocks require precise internal passages, smooth cylinder bores, and accurate mounting surfaces that can only be achieved through advanced CNC milling operations. These components typically utilize high-strength steel and aluminum alloys processed through multi-stage machining operations that include roughing, semi-finishing, and precision finishing cuts to achieve final dimensional tolerances. High precision CNC milling parts for brake applications undergo rigorous quality testing and certification processes, with specialized anodizing and plating treatments providing corrosion resistance and enhanced durability in harsh operating environments.

Suspension and Steering Components

Suspension systems require high precision CNC milling parts for control arms, steering knuckles, and shock absorber components where dimensional accuracy affects vehicle handling, ride quality, and tire wear characteristics. These components often feature complex geometries with multiple mounting points, precision bearing surfaces, and intricate internal passages for hydraulic systems. The manufacturing process typically involves multi-axis CNC machining operations using steel, aluminum, and specialized alloys to create components that withstand extreme mechanical loads while maintaining dimensional stability. High precision CNC milling parts in suspension applications benefit from advanced surface treatments and quality control processes that ensure consistent performance across varying road conditions and vehicle loading scenarios.

Electronic Control Unit Housings

Modern vehicles incorporate numerous electronic control units that require high precision CNC milling parts for protective housings, heat sinks, and connector mounting systems. In order for connectors to fit properly and for heat to be managed, these parts must block electromagnetic radiation and keep their exact dimensions. Precision milling of aluminum and steel with special surface treatments that improve electrical conductivity and corrosion resistance is used in the production process. High precision CNC milling parts for electronic applications undergo rigorous testing for dimensional accuracy, surface finish quality, and environmental resistance, ensuring reliable protection for sensitive electronic components throughout the vehicle's service life.

Advanced Manufacturing and Quality Control

Multi-Material Processing Capabilities

The automotive industry increasingly demands high precision CNC milling parts that incorporate multiple materials within single assemblies, requiring advanced manufacturing techniques that can process steel, aluminum, brass, and specialized alloys in integrated production sequences. These multi-material components often feature dissimilar material joints, precision-fitted interfaces, and complex geometries that challenge traditional manufacturing approaches. Modern CNC machining centers equipped with automatic tool changers and multi-axis capabilities enable the production of these sophisticated components while maintaining dimensional accuracy and surface finish requirements. High precision CNC milling parts manufactured through multi-material processes benefit from comprehensive quality control systems that monitor dimensional accuracy, surface integrity, and material compatibility throughout the production cycle.

Advanced Surface Treatment and Finishing

Finishing and surface treatment processes are very important for making sure that high precision CNC milling parts for automotive applications work as well as possible. Specialized methods, such as anodizing, plating, and thermal treatments, make parts last longer, be less likely to rust, and wear better while keeping the exact dimensions the same. Care must be taken during these finishing steps to avoid changes in size that could affect how well parts fit and work in important vehicle systems. In order to meet the reliability needs of modern car manufacturing, high precision CNC milling parts go through extensive surface analysis and quality verification processes that guarantee consistent finish quality and dimensional accuracy across production batches.

Quality Assurance and Certification Standards

Quality assurance plans that include material certification, dimensional verification, and performance testing throughout the manufacturing process are needed for high precision CNC milling parts used in the automotive industry. ISO 9001:2015 quality management systems set the rules for consistent quality control, and specific car standards make sure that parts are safe and reliable. As part of the quality assurance process, advanced metrology equipment and statistical process control methods are used to inspect incoming materials, keep an eye on work in progress, and check the end product. For automotive use, high precision CNC milling parts are put through strict testing procedures that check for accuracy in dimensions, quality of the surface finish, and material properties. This makes sure that the parts always work well and reliably in harsh automotive conditions.

Conclusion

All automotive systems, from engine assemblies to computer control units, rely on high precision CNC milling parts as essential parts. Modern automakers can meet performance, economy, and safety goals while keeping production costs low thanks to their high level of accuracy in measurements, quality of surface finish, and ability to work with a wide range of materials. These parts meet the strict requirements of modern car engineering because they are made with advanced manufacturing technologies and full quality control systems.

Partner with Wuxi Kaihan Technology Co., Ltd., your trusted high precision CNC milling parts manufacturer and supplier, to enhance your automotive manufacturing capabilities. Our ISO 9001:2015 certified facility combines China's supply chain cost advantages with proven expertise in precision CNC machining, EDM, grinding, and advanced surface treatments. With 30-40% cost savings, 10-20 working day lead times, and comprehensive OEM/ODM services, we deliver high precision CNC milling parts factory solutions tailored to your automotive requirements. Our wholesale high precision CNC milling parts support applications across engine systems, chassis components, and electronic assemblies. Contact our experienced team at service@kaihancnc.com to discuss your specific automotive component needs and discover how our advanced manufacturing capabilities can optimize your production efficiency.

References

1. Johnson, M.R. "Precision Manufacturing in Automotive Engine Components." Automotive Engineering International, Vol. 131, No. 4, 2023, pp. 45-58.

2. Liu, H.K. "Advanced CNC Machining Techniques for Automotive Transmission Components." Journal of Manufacturing Science, Vol. 29, No. 6, 2023, pp. 178-192.

3. Martinez, C.A. "Quality Control in High-Precision Automotive Component Manufacturing." International Journal of Automotive Technology, Vol. 24, No. 3, 2023, pp. 89-103.

4. Thompson, D.L. "Multi-Material Processing in Modern Automotive Manufacturing." Manufacturing Technology Review, Vol. 42, No. 8, 2023, pp. 156-171.

5. Zhang, W.F. "Surface Treatment Technologies for Automotive Precision Components." Materials and Manufacturing Processes, Vol. 38, No. 12, 2023, pp. 234-248.

Roberts, P.J. "CNC Milling Applications in Automotive Safety Systems." Automotive Safety Engineering, Vol. 19, No. 2, 2023, pp. 67-82.

Learn about our latest products and discounts through SMS or email