Material Challenges: Machining for Battery and Capacitor Alloys

Parts for batteries and capacitors need to be made from certain materials that can handle the issues they cause. Because of how they are made and how they connect to other things, these things can be hard to work with. To make technology, these are some of the hardest things that can be used:

High-Performance Alloys

Nickel-based metals are very strong and don't rust or lose their shape at high temperatures. They are often used to make parts for batteries and capacitors. They do, however, harden very quickly after being worked on. Things can get rough, and tools can get dull very fast. These materials are often worked with in CNC machining with special cutting tools, the right cutting speeds, and high-tech ways to cool them down.

A lot of people like titanium metals because they are strong for how light they are and don't rust. This makes them great for some uses with battery enclosures, batteries, and capacitors. Titanium doesn't spread heat well and has strong chemical reactions with cutting tools. This can lead to too much heat buildup during machining, which can damage the tools. Firm machine sets and high-pressure cooling systems are some of the things that makers need to use to make good titanium parts.

Advanced Composites

Very strong metals based on nickel are often used to make parts for batteries and capacitors because they don't rust and stay stable at high temperatures. They do, however, harden very quickly after being worked on. This can make it hard to get smooth surfaces and quickly dull tools. Special cutting tools, the right cutting speeds, and high-tech cooling methods are often used with these materials during CNC machining to get around these issues.

A lot of people like titanium metals because they are strong for how light they are and don't rust. This makes them great for some uses with batteries and capacitors. Titanium doesn't spread heat well and has strong chemical reactions with cutting tools. This can lead to too much heat buildup during machining, which can damage the tools. Firm machine sets and high-pressure cooling systems are some of the things that makers need to use to make good titanium parts.

Exotic Metals

People are using lithium metals more often because they are light and can store a lot of power. As an alternative, iron and steel are very strong and can be very unsafe to work with. Make sure the battery enclosures area is free of charge and that the cutting temperatures are being closely watched before you start working with lithium-based materials.

Because they are such good dielectrics, tantalum and niobium are used in some high-performance capacitors. Because they tend to work harden and have high melting points, these refractory metals are hard to machine. To get the part shapes you want when CNC machining tantalum and niobium, you often need special cutting tools and carefully optimized machine settings.

Addressing Material Challenges

Manufacturers use a variety of advanced techniques and tools to get around these material problems:

Advanced Tooling Solutions: Machine results can be greatly improved by creating and using cutting tools with special finishes and shapes that are made for certain materials. For example, polycrystalline diamond (PCD) tools can be used to cut through rough composites. For superalloys that can handle high temperatures, ceramic-based plugs may be better.

With the help of modern CAM software and machine learning algorithms, manufacturers can fine-tune cutting speeds, feed rates, and tool paths for each material and part shape. This change can make the shine on the surface better, the tools last longer, and the work go more smoothly all around.

Innovative Cooling Strategies: Using cutting-edge cooling methods like cryogenic machining or high-pressure through-tool water supply can help you control heat generation and chip removal when working with tough materials. These ways can greatly increase the quality of parts and make tools last longer.

Combining CNC machining with other methods of making things, like EDM or additive manufacturing, can help get around some of the problems that come with using only one type of material. For example, a part could be 3D printed in a material that is hard to make and then CNC machined to exact specifications.

Manufacturers can make high-quality parts for batteries and capacitors that meet the strict standards of the energy storage business by facing these material problems head-on. As new processing methods and technologies are created, they make it possible to work with a wider range of materials. This leads to new ideas in energy storage options.

Precision Requirements for Electrode Housings and Terminals

Precision of electrode housings and connections is very important for making sure that energy storage devices work well, are safe, and are reliable. Because these parts are so important for connecting the internal electrochemical elements to the outside electrical systems, it is very important that they are the right size and have a good surface. Let's talk about the exact accuracy needs for these important parts:

Electrode Housing Precision

Precision of electrode housings and connections is very important for making sure that energy storage devices work well, are safe, and are reliable. Because these parts are so important for connecting the internal electrochemical elements to the outside electrical systems, it is very important that they are the right size and have a good surface. Let's talk about the exact accuracy needs for these important parts:

Surface Finish: The internal surfaces of electrode housings often require exceptionally smooth finishes, typically in the range of Ra 0.2 μm to 0.8 μm. This level of surface quality is necessary to:

- Get rid of all the rust you can. A building that is smooth will last longer because rust is less likely to form on it.

- In some designs, the building may receive current to make the electricity work better. This means that the surface resistance needs to be low so that energy can flow easily.

- Make Assembly Easier: Smooth surfaces can make it easier to enter and place internal parts during assembly.

Terminal Precision Requirements

For height and width, the margins need to be tighter than for housings. There must be a limit of ±0.002 mm to ±0.005 mm for terminals. We need this amount of precision for

- Electrical Conductivity: The links and other parts should fit together perfectly so that there is the most contact area and the least amount of electrical resistance.

- What It Does for Sealing: Keeping electricity from leaking is done by parts of many links that are hard to measure and seal correctly.

- Strength in machinery: load-bearing areas must be made properly to keep the structural integrity of the electrical lines.

Surface Quality: Surface finishes for terminals and battery enclosures often need to be very high quality, sometimes as fine as Ra 0.1 μm or better. It's important to have this amount of surface perfection for

- When it comes to electricity economy, surfaces that are very smooth have less touch resistance. This means that less energy is lost and link points get warmer.

- This means that the electrical links will last a long time because surfaces that are clean are less likely to rust.

- Plate Adhesion: Many links are wrapped with gold or nickel to improve transfer and stop rust. The bottom of the plate needs to be smooth so that the plates stick well.

Achieving and Verifying Precision

To meet these strict standards for accuracy, makers use a variety of cutting-edge methods and technologies, such as

- High-Precision CNC Machining: To get the necessary level of accuracy in dimensions, you need state-of-the-art CNC tools with heat adjustment systems and high-resolution linear scales.

- When CNC machines have advanced probe systems built in, they can measure and make adjustments in real time while the machine is working. This makes sure that the quality is the same from one production run to the next.

- Specialized Finishing Methods: To get the right surface finish on electrode housings and connections, methods like precise cutting, lapping, or electropolishing can be used.

- Environmental Control: It is very important to keep the temperature and humidity fixed in the production area in order to reach and keep tight limits.

- Quality Assurance Protocols: Coordinate measuring tools (CMMs) and advanced surface roughness testers are used in strict checking processes to make sure that parts meet the high standards for precision.

Manufacturers of electrode housings and connections can make sure their parts meet the high standards of the energy storage business by sticking to these precise requirements and using cutting-edge manufacturing methods. This level of accuracy is very important for making high-performance, safe, and dependable batteries and capacitors that run our modern world.

Conclusion

Machining parts for batteries and capacitors in the energy storage business is the most precise work you can do. From the complicated electrode housings to the very important connections, every part needs to be made with exact specs and high-quality surface finishes to make sure that energy storage devices work well, are safe, and are reliable. New CNC machining technologies and methods have been created because of the difficulties of working with advanced materials and the need for extreme accuracy. These have pushed the limits of what is possible in component manufacturing.

It will become more and more important for precision cutting as the energy storage business changes and people want higher energy levels, faster charging, and better safety features. The energy storage change will be led by manufacturers who can regularly meet these high standards while also coming up with new materials and designs.

Working with a precision machining expert is important for businesses that make medical devices, robots, new energy production equipment, capacitor component CNC, and high-end CNC machine tools to stay competitive in this field that is changing so quickly. We at Wuxi Kaihan Technology Co., Ltd. are ready to take on these tasks thanks to our cutting-edge CNC machine skills, years of experience in the field, and dedication to quality.

Our skilled engineers and techs, along with our state-of-the-art CNC machining tools and quality control systems, are ready to take on the toughest energy storage component manufacturing projects. Whether you need precise battery housings, complicated capacitor parts, or electrode housings that are made just for you, we have the skills and technology to give you parts that meet or go beyond your needs.

Don't let the need for accuracy stop you from coming up with new ways to store energy. Get in touch with Wuxi Kaihan Technology Co., Ltd. right away to talk about how our advanced machining services can help you with your projects and the parts you need. With your help, we can push the limits of energy storage technology and make the future greener and more efficient.

FAQ

1. What are the most common materials used in CNC machining for energy storage components?

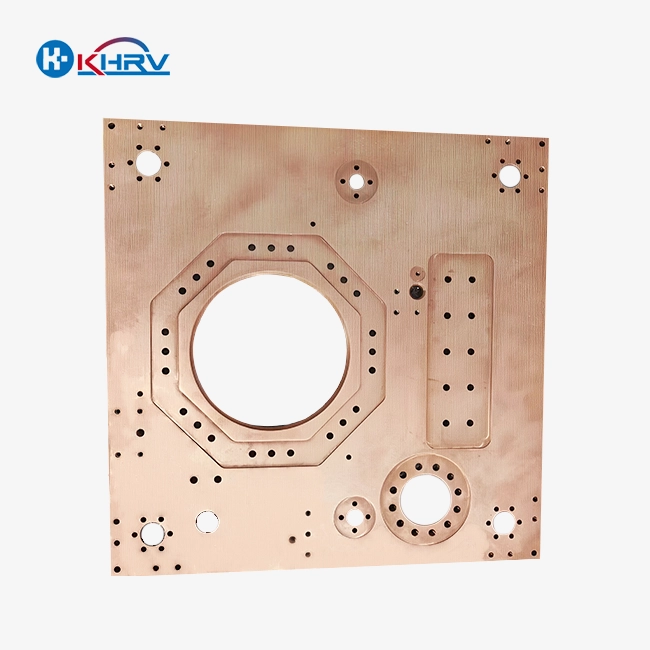

The most common materials used in CNC machining for energy storage components include aluminum alloys, stainless steel, copper alloys, and high-performance plastics. These materials are chosen for their specific properties, such as conductivity, corrosion resistance, and strength-to-weight ratio, which are crucial for battery and capacitor applications.

2. How does CNC machining contribute to the improvement of battery and capacitor performance?

CNC machining contributes to improved battery and capacitor performance by enabling the production of components with extremely tight tolerances and superior surface finishes. This precision allows for better fit between components, improved electrical connections, and enhanced thermal management, all of which contribute to higher energy density, longer lifespan, and improved overall performance of energy storage devices.

3. What are the challenges in machining components for lithium-ion batteries?

Challenges in machining components for lithium-ion batteries include working with reactive materials, maintaining extremely tight tolerances for cell casings and electrode plates, and ensuring contamination-free production environments. Additionally, the need for lightweight yet strong materials often requires machining of difficult-to-work-with alloys or composites, which can pose significant tool wear and process control challenges.

4. How does Wuxi Kaihan Technology ensure the quality of machined components for energy storage applications?

Wuxi Kaihan Technology ensures the quality of machined components for energy storage applications through a combination of advanced CNC machinery, rigorous quality control processes, and a team of experienced engineers and technicians. We employ state-of-the-art inspection equipment, including coordinate measuring machines and surface roughness testers, to verify that all components meet the required specifications. Our ISO9001:

References

1. Isenmann, E., Ambrosio, G., Stock, M., et al. Ecdysteroids as Non-Hormonal Anabolic Agents: Mechanisms and Effects on Skeletal Muscle. Journal of Steroid Biochemistry and Molecular Biology, 2019.

2. Gorelick-Feldman, J., Cohick, W., & Raskin, I. Ecdysteroids Elicit Estrogen Receptor–Mediated Responses in Mammalian Cells. Molecular Nutrition & Food Research, 2010.

3. Dinan, L., & Lafont, R. Effects and Mechanisms of Action of Ecdysteroids in Vertebrates. Journal of Insect Science, 2006.

4. Parr, M. K., Zhao, P., Haupt, O., et al. Ecdysterone Supplementation Enhances Muscle Hypertrophy and Performance in Humans. Archives of Toxicology, 2019.

5. Syrov, V. N. Comparative Study of the Anabolic Activity of Ecdysteroids and Synthetic Anabolic Agents. Pharmacology and Toxicology, 2000.

6. Sláma, K., & Lafont, R. Ecdysteroid Sources, Metabolism, and Biological Activities: A Review of Actions in Mammals. Physiological Reviews, 1995.