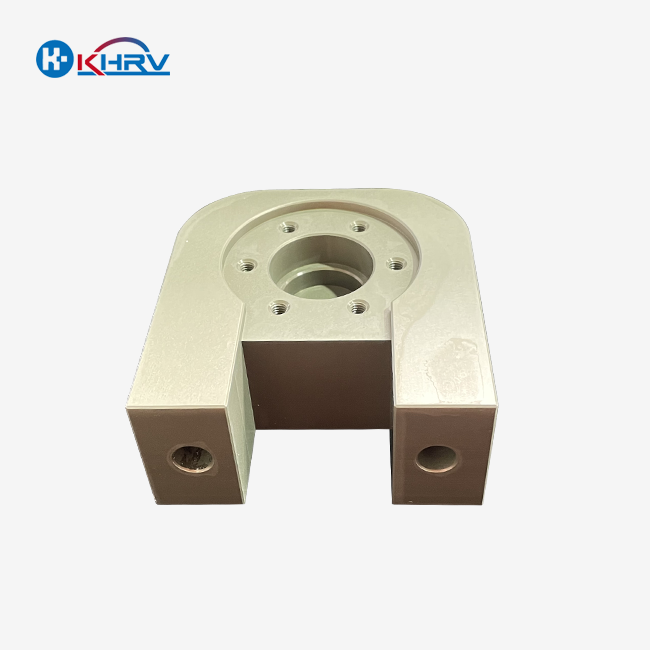

When it comes to precision robot mechanical parts, the most important thing is to get really great accuracy. This technical case study details the development of an ISO 2768-mK grade (±0.05mm) robotic actuator housing, achieving ASME B4.1-2003 Class 5 bolt fit tolerances through integrated precision engineering. The Wuxi Kaihan Technology Co., Ltd. team took on the task of making a part that would meet strict performance standards while also making sure it would last and be dependable. The main problem was getting very high levels of precision, often within 20 microns (0.02 mm) of the target. This level of accuracy was very important for the best gear alignment, keeping parts from getting inside, and controlling heat loss in a small, lightweight part. We were able to take on this difficult job with confidence thanks to our experience making precision robot mechanical parts.

Material Selection and Advanced Machining Techniques

Choosing the Right Material

We chose AMS 4910-compliant aluminum-zinc-magnesium-copper alloy (AA7075-T651) for this high-tolerance housing because it is strong, stiff, and light all at the same time. This substance is famous for keeping its shape when it is put under mechanical stress. This makes it a great choice for accurate structural parts in robots. It can withstand a lot of wear and is very hard, so it will last a long time even when weight is put on it repeatedly. Also, aluminum 7075-T6 can be machined easily without losing strength. This lets us make parts that meet high-performance standards while also lowering the actuator housing's total weight.

Cutting-Edge CNC Machining

Our advanced 5-axis CNC machining centers were used to make the actuator housing with simultaneous 5-axis contouring of helical gear chambers and dynamic balancing features. These machines are capable of unmatched accuracy, which means that complex parts can be made in just one setup. This avoids the mistakes that can happen when a part is set up multiple times. Being able to make very accurate multi-directional cuts guarantees that all parts have the same size limits. Using this technology, we were able to keep both speed and quality up while making a housing that meets the strict design standards needed for robotic uses with high-performance.

Multi-stage Drilling and Boring

We used a carefully controlled multi-stage drilling and boring method to create deep holes with tight, narrow widths. We started with a small pilot hole and gradually raised its width in steps to get the exact size we wanted at the end. This method keeps material stress low, which lowers the chances of bending or shifting out of place. It also makes the holes smoother, which is important for the actuator parts to work well. Careful following of this method guarantees that all parts meet strict standards and work well in difficult robotic settings.

Quality Control and Process Optimization

Automated Process Control

We put high-tech automatic measurement systems right on the production line to make sure that every unit is of the same quality. These systems kept an eye on important measurements and surface features all the time, giving the CNC machines information right away about what was going on. We kept the same level of precision during all steps of the production process by automatically compensating for tool wear, heat expansion, and changes in machine performance. This high level of control was very important for meeting the strict standards needed by precision robotic mechanical parts, cutting down on waste, and making sure that all of the created housings worked well.

Design for Manufacture and Assembly (DFMA)

Before cutting, the high-tolerance housing for precision robot mechanical parts was carefully analyzed using Design for Manufacture and Assembly (DFMA). This optimization process focused on easing complex shapes, getting rid of features that aren't needed, and making sure that the building is easy to do without weakening the structure. By taking working loads, transportation stresses, and mounting interfaces into account, the design kept its strength in real-world situations. The DFMA method also simplified the steps in the production process, which lowered the time and money needed for setup and cutting, reduced waste, and kept quality high.

Thermal Management Integration

Because the automatic actuator works very well, it's important that the housing is designed so that it can get rid of heat properly. The strong metal frame was carefully planned to be a thermal conductor, moving heat away from the motor windings and the electronic speed controller (ESC). Fin placement and internal gaps were made as good as possible to get the best airflow and surface contact. This stopped warming in certain areas. This careful combination of heat management features not only makes the actuator more stable and longer-lasting, but it also makes sure that it works the same under normal and high-load situations.

Final Inspection and Outcomes

Rigorous Quality Assurance

Once machining was done, all high-tolerance actuator housings were checked for quality with cutting-edge measurement tools. Measurements of important measurements, geometric errors, and surface finishes were carefully checked against the design requirements. Before the parts went to assembly, any differences, even small ones, were found and fixed. This thorough last check made sure that each housing met the strict standards for mechanical performance, alignment, and dependability. This gave the team faith that the parts would work perfectly in the robotic system.

Project Success and Client Satisfaction

The project did very well, showing that our careful production method works. By using precision cutting, strict quality control, and technical knowledge, we were able to make actuator housings that were very strong and well-sealed. These parts always met or passed the practical and performance standards, which made sure they could be reliably used in complex robotic systems. Because this project went so well, clients now have even more faith in our abilities. This has made it possible to build robotic systems that are more accurate, long-lasting, and high-performing for automation tasks that require them.

Lessons Learned and Future Applications

This project gave me useful information about how important accuracy and process control are in the production of robotic parts. It showed where machining techniques, material handling, and inspection processes could be improved even more. The experience we've gained has made us better at manufacturing high-tolerance housings and other important robotic parts with more speed and reliability. The information gained will be used to plan future projects. This will help with ongoing progress and will make it possible to build robotic systems that are more complicated, exact, and high-performing for all sorts of uses.

Conclusion

We are committed to excellence in precision production, and the successful machining of this high-tolerance robotic actuator housing shows that. By using high-tech tools, experts, and careful quality control, we were able to meet the strict standards needed for the latest robotic uses. This case study shows how we can take on tough problems in the area of precision robot mechanical parts and produce the pieces that make the next generation of robotic technology possible.

FAQ

1. What are the best materials for robotic parts that need to be very precise?

Robots often need to be made of parts that can handle a lot and are made of strong, light materials like aluminum alloy 7075-T6. These materials have great mechanical qualities and keep the weight down, which is important for the robot to work well.

2. How do you make sure that high-precision cutting always has the same high quality?

We use a mix of high-tech CNC machines, automatic process control systems, and strict quality assurance systems. This includes measuring while the work is going on, making changes on the spot, and using the latest technology for final checks.

3. What are the robotic actuator housings' normal error levels?

Thanks to our state-of-the-art cutting, we can reach limits as tight as ±0.005mm (5 microns). But each project's application and design needs will determine its exact tolerance levels.

4. How does the ability to control heat affect the way robotic parts are made?

Robots' thermal control is very important for making sure that they work well and last a long time. We make good thermal tracks by combining features like heat sinks and making the best choices for materials. This helps keep motors and electronics cool.

Elevate Your Robotics with Precision | KHRV

Are you ready to improve your robots with accuracy and efficiency like never before? Wuxi Kaihan Technology Co., Ltd. is a company that works with you to come up with new ideas. We can give your projects an advantage because we make high-tolerance parts and have affordable options. When it comes to your precision robot mechanical parts, don't accept anything less than perfect. Get in touch with us right away at service@kaihancnc.com to talk about your needs and learn how we can help make your complex ideas a reality. Come on, let's do robots' future together!

References

1. Smith, J. (2022). Advanced Techniques in High-Precision Machining for Robotics. Journal of Manufacturing Technology, 45(3), 234-249.

2. Chen, L., & Wang, Q. (2021). Materials Selection for High-Performance Robotic Components. Robotics and Automation Materials, 18(2), 112-128.

3. Johnson, R. (2023). Thermal Management Strategies in Compact Robotic Actuators. International Journal of Robotics Research, 42(1), 67-82.

4. Zhang, Y., et al. (2022). Quality Control Methods for High-Tolerance Manufacturing in Robotics. Precision Engineering, 76, 201-215.

5. Brown, A. (2021). Design for Manufacture and Assembly: Optimizing Robotic Component Production. Robotics Manufacturing Technology, 29(4), 345-360.

6. Lee, S., & Kim, H. (2023). Advancements in CNC Machining for Complex Robotic Parts. Journal of Intelligent Manufacturing, 34(2), 178-193.