The Interplay Between Spindle Power, Torque, and Speed in CNC Machining

Understanding the relationship between spindle power, torque, and speed is fundamental to maximizing the performance of your CNC machine. These three factors are interconnected and directly influence the machine's ability to handle various cutting operations effectively.

Spindle Power: The Driving Force Behind CNC Operations

Spindle power, ordinarily measured in horsepower (HP) or kilowatts (kW), refers to the general capacity of the CNC machine to perform cutting assignments. It decides the sum of vitality accessible to drive the cutting apparatus through the workpiece. Higher spindle power, for the most part, translates to expanded machining capabilities, permitting for more forceful cuts, quicker material removal rates, and the ability to work with harder materials.

When evaluating spindle power requirements, consider the following:

- Material hardness: Harder materials like steel or titanium require more control to machine effectively.

- Depth of cut: More profound cuts require more control to keep up cutting speed and nourish rates.

- Tool estimate: Bigger cutting instruments, by and large, require more control to work efficiently.

- Production volume: High-volume generation may benefit from higher spindle power to keep up reliable

Torque: The Rotational Force That Drives the Cut

Torque, measured in Newton-meters (Nm) or foot-pounds (ft-lb), speaks to the rotational drive connected to the cutting device in CNC Machine Selection. It plays a pivotal part in deciding the machine's capacity to keep up with cutting constraints, particularly at lower axle speeds. Tall torque is especially imperative when working with difficult materials or when making overwhelming cuts that require critical control to evacuate fabric efficiently.

Key considerations for torque requirements include:

- Material characteristics: Harder materials frequently require higher torque to anticipate the instrument slowing down amid cuts.

- Cutting methodology: Roughing operations ordinarily require more torque than wrapping up operations.

- Tool geometry: A few cutting devices, like expansive breadth confront plants, may require higher torque to work effectively.

- Spindle speed run: Assess the torque bend over distinctive axle speeds to guarantee satisfactory constrain all through your planning working range.

Speed: The RPM Factor in Machining Efficiency

Spindle speed, measured in revolutions per minute (RPM), is the rate at which the cutting device turns. The ideal axle speed shifts depending on the fabric being machined, the cutting device utilized, and the wanted surface wrap. By and large, milder materials advantage from higher axle speeds, whereas harder materials require lower speeds to anticipate apparatus wear and maintain cutting efficiency.

Consider these factors when determining optimal spindle speeds:

- Material properties: Milder materials like aluminum or plastics frequently permit higher axle speeds, whereas harder materials like steel require lower speeds.

- Cutting apparatus determinations: Each cutting apparatus has an ideal speed range for top execution and longevity.

- Surface wrap-up necessities: Higher speeds can frequently accomplish better surface wraps, especially in milder materials.

- Heat era: Adjusting speed with warm scattering is pivotal to anticipate warm harm to both the workpiece and the cutting tool.

Matching Spindle Characteristics to Specific CNC Applications

To achieve optimal performance in your CNC operations, it's essential to align spindle characteristics with your specific applications. This process involves carefully considering the materials you'll be working with, the types of cutting operations you'll perform, and the desired outcomes in terms of precision and surface finish.

Material-Specific Spindle Requirements

Different materials demand varying spindle characteristics for efficient machining:

Hard Metals (e.g., Steel, Titanium):

- High torque at lower RPMs to keep up with cutting constraints without stalling

- Moderate to tall control to handle the resistance of thick materials

- Robust axle development to withstand the stresses of overwhelming cutting

Soft Materials (e.g., Wood, Plastics, Foam):

- High RPM capabilities for quick, clean cuts

- Lower torque requirements due to diminished fabric resistance

- Emphasis on shaft speed steadiness for a reliable surface finish

Aluminum and Composites:

- High RPM (regularly 20,000+ RPM) for ideal cutting speeds and surface finish

- Balanced control and torque to handle changing densities inside composite materials

- Consideration for chip clearing to anticipate re-cutting and warm buildup

Application-Specific Considerations

The nature of your machining operations also influences spindle requirements:

Roughing Operations:

- Higher torque to evacuate large amounts of fabric efficiently

- Robust control to keep up with cutting constraints amid forceful fabric removal

- Lower RPM run to handle bigger cutting instruments and more profound cuts

Finishing Operations:

- Higher RPM capabilities for smooth surface finishes

- Precision shaft plan to minimize runout and vibration

- Consistent control conveyance over the RPM range for uniform cutting performance

High-Speed Machining:

- Very tall RPM capabilities (frequently 30,000+ RPM)

- Advanced axle plans to keep up stability at extraordinary speeds

- Consideration for warm administration to anticipate heat-induced inaccuracies

Evaluating Spindle Power and Torque Curves

When selecting a CNC machine in CNC Machine Selection, it's crucial to examine the spindle's power and torque curves. These graphs provide valuable insights into the spindle's performance across its entire speed range:

- Power Bend: Appears to be the accessible control at distinctive axle speeds, making a difference you decide if the axle can convey adequate control for your particular cutting operations over different RPMs.

- Torque Bend: Outlines the accessible torque at distinctive axle speeds, which is especially critical for operations requiring tall constrain at lower RPMs, such as when machining difficult materials or performing overwhelming roughing cuts.

- Constant Control Run: Distinguish the RPM range where the axle maintains its most extreme control yield, guaranteeing ideal execution for a variety of cutting conditions.

- Torque Crests: See for torque crests that adjust with your most common cutting speeds to maximize machining efficiency.

Optimizing CNC Performance Through Spindle Selection and Setup

Selecting the right spindle and optimizing its setup are critical steps in maximizing the performance and efficiency of your CNC operations as part of CNC Machine Selection. By carefully considering your specific application requirements and understanding how to fine-tune spindle parameters, you can significantly enhance machining outcomes and overall productivity.

Strategies for Effective Spindle Selection

When choosing a spindle for your CNC machine, consider the following strategies:

Comprehensive Application Analysis:

- Catalog all materials you expect to machine and their particular requirements

- List the sorts of cutting operations you'll perform (e.g., roughing, wrapping up, high-speed machining)

- Consider future generation needs to guarantee the shaft can suit potential changes in your manufacturing processes

Spindle Specification Evaluation:

- Compare control and torque bends of diverse axles to your application requirements

- Assess the RPM run and how it adjusts with your commonplace cutting speeds

- Consider extra highlights, such as through-spindle coolant capabilities or programmed instrument changing

Tooling Compatibility:

- Ensure the spindle's instrument holder interface (e.g., CAT, BT, HSK) matches your existing or arranged tooling inventory

- Verify that the shaft can accommodate the measure and weight of your biggest cutting tools

- Consider the spindle's inflexibility and its effect on device execution, particularly for accuracy applications

Fine-Tuning Spindle Parameters for Optimal Performance

Once you've selected an appropriate spindle, optimizing its parameters can further enhance machining performance:

Cutting Parameter Optimization:

- Utilize cutting apparatus manufacturers' suggestions as a beginning point for shaft speed and bolster rates

- Experiment with diverse combinations of shaft speed, nourish rate, and depth of cut to discover the ideal balance for each fabric and operation

- Monitor control utilization and cutting strengths to guarantee you're working within the spindle's capabilities

Vibration Management:

- Use accelerometers or built-in vibration observing frameworks to recognize and relieve destructive vibrations

- Adjust cutting parameters or instrument geometries to minimize chatter and improve surface finish

- Consider executing progressive vibration-damping advances for high-precision applications

Thermal Management:

- Monitor shaft temperature during operation to avoid warm extension and related precision issues

- Implement appropriate warm-up methods to guarantee reliable execution from the beginning of machining

- Utilize cooling frameworks effectively to keep up ideal working temperatures during amplified use

Leveraging Advanced Spindle Technologies

Staying abreast of the latest spindle technologies can provide significant advantages in CNC machining achining Capacity:

High-Frequency Spindles:

- Enable ultra-high-speed machining, make strides, surface wraps up, and decrease cycle times

- Ideal for working with materials that benefit from tall cutting speeds, such as aluminum or graphite

- Consider the trade-offs between speed and torque when assessing high-frequency options

Motorized Spindles:

- Offer coordinates engine plans for made strides, control transmission, and decrease maintenance

- Provide way better warmth steadiness and accuracy in high-speed applications

- Evaluate the long-term benefits against the beginning venture for your particular generation needs

Smart Spindle Systems:

- Incorporate sensors for real-time observing of axle execution and health

- Enable prescient support techniques to minimize unforeseen downtime

- Offer data-driven bits of knowledge for ceaseless handle change and optimization

Conclusion

Understanding and optimizing spindle power and torque prerequisites are significant for accomplishing peak performance in your CNC applications. By carefully considering the interaction between control, torque, and speed, and coordinating these characteristics to your particular materials and operations, you can altogether improve machining effectiveness and quality. Keep in mind to frequently assess and fine-tune your shaft parameters, and remain educated about rising axle innovations to keep up a competitive edge in your manufacturing processes.

For producers in businesses such as unused vitality generation gear, robot fabrication, high-end CNC machine tool fabrication, and restorative gadget fabrication, selecting the right CNC shaft is foremost. Whether you're managing with large-scale generation lines, progressing hardware overhauls, or accuracy component fabricating, the right shaft can make all the difference in assembling your generation objectives and quality standards.

FAQ

1. What is the importance of spindle power in CNC machining?

Spindle power, measured in HP or kW, determines the overall capacity of a CNC machine to perform cutting tasks. It's crucial for handling tough materials, making deeper cuts, and maintaining consistent performance in high-volume production. Adequate spindle power ensures efficient material removal and the ability to use larger cutting tools effectively.

2. How does torque affect CNC machining performance?

Torque, measured in Nm or ft · lb, represents the rotational force applied to the cutting tool. It's particularly important when working with hard materials or making heavy cuts at lower spindle speeds. High torque helps prevent tool stalling and maintains cutting force, especially in roughing operations or when using large diameter cutting tools.

3. Why is spindle speed (RPM) important in CNC operations?

Spindle speed, measured in RPM, affects cutting efficiency and surface finish quality. Higher speeds are generally beneficial for softer materials and finishing operations, while lower speeds are often necessary for harder materials to prevent excessive tool wear. The optimal speed depends on the material being machined, the cutting tool used, and the desired surface finish.

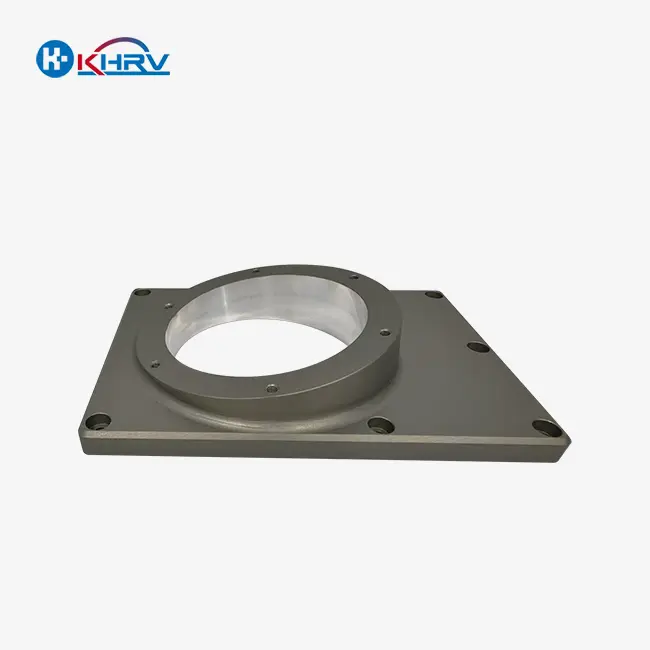

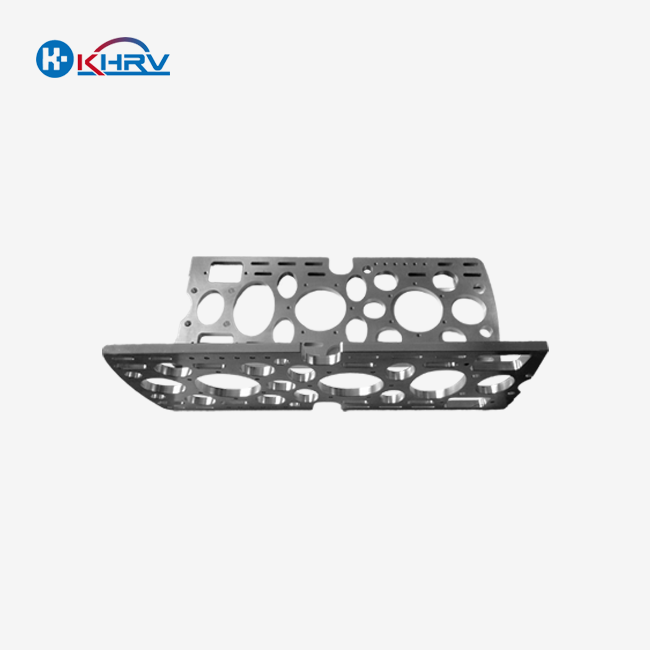

Unlock Precision with KHRV: Optimize Your CNC Machining Today

At Wuxi Kaihan Technology Co., Ltd., we understand the critical role that precision components play in your manufacturing processes, especially in CNC Machine Selection. As experts in CNC machining and key component production for artificial intelligence equipment, we offer tailored solutions to meet your specific spindle and machining needs. Our state-of-the-art facility, equipped with advanced CNC machining centers and a team of experienced professionals, ensures that we can deliver high-precision parts with quick turnaround times.

Take advantage of our expertise in OEM processing, cross-border semi-finishing solutions, and precision multi-material machining. With our ISO9001:2005 certified quality management system and cost-effective approach, we can help you optimize your CNC operations while reducing costs by 30-40% compared to European and American manufacturers.

Don't let spindle selection challenges hinder your productivity. Contact us today at service@kaihancnc.com to discuss how we can support your CNC machining needs and help you achieve optimal performance in your applications.

References

1. Benard, J., & Kops, M. (2017). "CNC Machining: Principles and Applications." New York: Industrial Press.

2. Fischer, T., & Schaefer, R. (2015). "Fundamentals of CNC Machining: A Comprehensive Guide." London: Springer.

3. Gibbons, M., & Hurst, D. (2019). "Spindle Design and Performance in CNC Machining." Journal of Manufacturing Science and Engineering, 141(6), 061001.

4. Reeve, J., & Thomas, L. (2018). "Understanding the Dynamics of CNC Spindles." Precision Engineering, 53, 47-55.

5. Smith, R., & Jones, P. (2020). "Torque Requirements and Power Calculations for CNC Operations." International Journal of Advanced Manufacturing Technology, 107(1), 123-134.

6. Wang, Y., & Chen, J. (2021). "Optimizing Spindle Performance in CNC Machining: A Study on Power and Torque." Robotics and Computer-Integrated Manufacturing, 67, 102-110.