An interesting process that blends creativity, exact engineering, and stringent quality control is the creation of customized medical device components for surgical instruments. This complex journey takes big, vague ideas and turns them into real, life-changing tools that are used in medical treatments around the world. From the first idea to the finished product, every step in making a custom medical surgery tool is important for making sure that it is safe, effective, and dependable. This piece will go over the many steps involved in making a special surgical tool, focusing on the most important parts of this amazing engineering achievement.

Conceptualization and Design: Laying the Foundation for Innovation

The first step in making a custom medical surgery tool is to come up with an idea. This often happens when a healthcare worker shares their experience or a clinical need that isn't being met. During this first part, there is a lot of study, brainstorming, and work together of medical experts, engineers, and designers.

Identifying Clinical Needs and Defining Objectives

The first step in making a new medical tool is to clearly state the problem it is meant to fix or the way it is meant to improve things. This includes:

- Doinga deep market study to find gaps in tools that are already out there

- Getting feedback from doctors and other medical experts about what they need and what's hard for them

- Looking at current surgery methods and finding ways they could be made better

The design team can focus on making a tool that will really help doctors do better surgeries and take better care of patients if they set clear goals.

Initial Design and Prototyping

The real planning part starts when the goals are clear. At this point,

- Making 3D models and precise drawings with computer-aided design (CAD) tools

- Making the first models, often with fast development technologies like 3D printing

- Testing the plan to see if it can be made and will work.

The modeling phase is very important because it lets creators quickly improve their ideas by making changes based on doctors' feedback and the results of early tests.

Material Selection and Engineering Considerations

Choosing the right materials for a medical device is very important for its success. Things that should be thought about are:

- Biocompatibility makes sure that the tool is safe to use on or in the body.

- Resistance to rusting, corrosion, and wear, as well as durability

- The power to be sterilized to meet strict cleanliness standards

- Weight and how well the design of an object allows it to be used during surgery

Engineers have to carefully balance these things. To meet the strict needs of surgical tools, engineers often use high-tech materials like medical-grade stainless steel, titanium alloys, or high-performance plastics.

Engineering and Manufacturing: Bringing the Design to Life

When the design is finished and the materials are chosen, the next step is to focus on the complex process of making the custom surgery tool. In this step, the conceptual form is turned into a working instrument that is made exactly right.

Precision Manufacturing Techniques

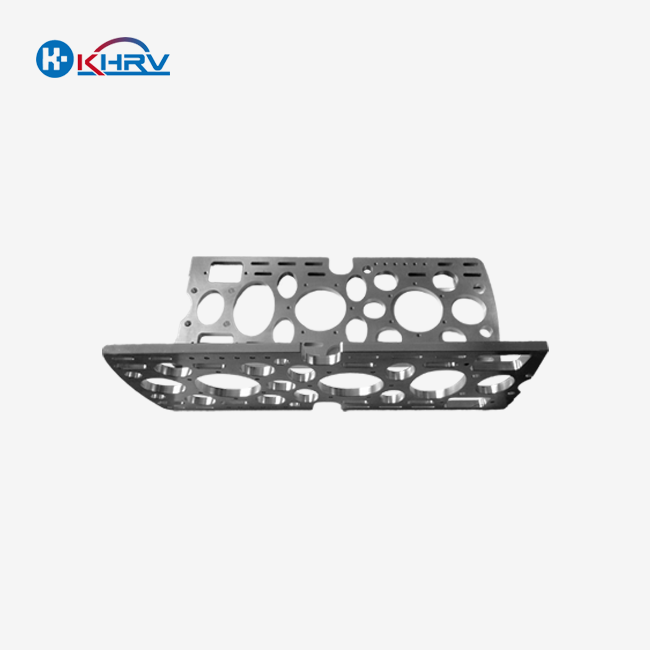

Customized medical device components are frequently made using a variety of advanced manufacturing methods, such as:

- Computer Numerical Control (CNC) machining for making very precise, complicated shapes

- Electrical Discharge Machining (EDM) for making complex forms in metals that are hard

- Using lasers for cutting and welding to get exact cuts and strong joins

- Additive manufacturing, or 3D printing, for making complicated custom parts

Each of these methods is very important for turning basic materials into the finished parts that make up the surgical tool. The needs of each part are taken into account when deciding on a manufacturing method. This includes finding a balance between the level of accuracy needed, the characteristics of the materials, and the number of parts that need to be made.

Quality Control and Testing

During the manufacturing process, strict quality checks are done on each part to make sure they meet the high standards needed for medical devices. This includes

- Dimensional checks with very accurate measurement devices

- X-ray and acoustic screening are examples of non-destructive testing methods.

- Functional testing to make sure that moving parts and systems work properly

- A study of the materials to ensure the qualities and makeup of the parts

These quality control steps are very important to make sure that the finished product will work safely and dependably in hospital settings.

Assembly and Finishing

The building step comes next for parts that have passed quality control. At this point,

- Precision assembly of parts, which often needs special tools and methods

- Using surface processes to make things more durable and resistant to rust

- Final cleaning and finishing to get the right look and surface quality.

The building process is closely monitored to make sure that each tool matches the exact details that were laid out in the planning phase.

Validation and Regulatory Compliance: Ensuring Safety and Efficacy

Before a new medical tool can be used in clinical practice, it must go through a lot of testing and get permission from the government. In this last step, it is very important to show that the medical device is safe and works well.

Clinical Validation

Clinical validation means using the surgery tool in settings that are very similar to how it will actually be used. This could include

- Putting in a lot of work to test simulated use in labs

- Cadaver studies to find out how well the tool works in settings that are right for anatomy

- Clinical studies with a small number of people in very controlled settings

The information collected in these evaluation studies is very important for showing regulatory agencies that the tool is safe and works well.

Regulatory Submission and Approval

Getting regulatory permission is a difficult task that includes

- Making a lot of documents that explain the planning, production, and testing methods

- Putting in a legal application to groups like the FDA or the European Medicines Agency

- Answering questions and giving extra information when government bodies ask for it

- Making any changes that need to be made to follow the rules.

The regulatory clearance process can take a long time and be hard, but it is important to make sure that only medical devices that are safe and work well are sold.

Post-Market Surveillance

The trip doesn't end when a surgical tool is accepted and put on the market. It is very important to keep an eye on post-market tracking for

- Keeping an eye on the device's long-term performance and safety

- Finding out how well it works in different kinds of medical situations.

- Finding any problems or places that could be improved

- Making sure that the rules that are always changing are followed

This ongoing process of observation and growth helps to fine-tune the tool over time, making sure that it continues to meet the changing needs of healthcare workers and patients.

Conclusion

Making a custom medical surgery tool is a difficult process that goes from idea to finished part. It requires skill, exactness, and a strong dedication to safety and quality. Each step in this process, from the first thought to the last approval by the government, is important to make sure that the finished product will meet the high standards of today's healthcare settings.

The prospects for new developments in surgical tools and customized medical device components are endless as technology keeps moving forward. We can better respect the amazing engineering and hard work that goes into making these life-changing tools when we understand and enjoy the complex process behind their creation.

It is important for medical device makers and healthcare workers who want to get new surgical tools into the market to work with precise engineering companies that have a lot of experience. Wuxi Kaihan Technology Co., Ltd. makes and processes precision parts for medical devices and other machines. We can help you make unique surgery tools from idea to part because we have the newest CNC machining centers, EDM capabilities, and strict quality control processes. Our team of skilled engineers and workers is dedicated to making high-quality, precision-engineered parts that meet the strict requirements of the medical field.

FAQ

1. What are the most important things to think about when making custom medical surgery tools?

Some important things to think about are figuring out clinical needs, making sure materials are biocompatible, improving comfort for surgery use, meeting sterilization standards, and following the rules. The planning process also includes making a lot of prototypes and tests to make sure they work and are safe.

2. How much time does the average unique surgery tool take to be made?

The time it takes to create a tool can vary a lot based on how complicated it is and what the rules say. It usually takes 18 months to 3 years for a product to get market approval after the idea is formed. This includes the time needed for testing, design, making the prototype, setting up the factory, and getting governmental permission.

3. How important is precise engineering in making medical devices?

When making medical devices that meet very strict safety and usefulness standards, precision engineering plays an important role. It makes sure that parts are made with very little room for error, often measured in microns. This level of accuracy is very important for the surgery tools to work correctly, and it can have a direct effect on the patient's results.

4. How do you make sure that unique medical devices are safe and effective?

Testing has many steps, such as lab tests to check the qualities of the material, simulated use testing, and often clinical studies. Devices are checked for quality in a very strict way. They are measured, tested to see if they work, and checked to see if they are clean. Before a gadget can be used by people, regulatory bodies need to see a lot of paperwork about these tests.

Transform Your Medical Device Concepts into Reality | KHRV

Are you ready to bring your innovative medical device ideas to life? Wuxi Kaihan Technology Co., Ltd. offers cutting-edge precision engineering services tailored to the medical industry. Our state-of-the-art CNC machining centers and experienced team can help you navigate the complex journey from concept to component.

Take the first step towards realizing your medical device innovations. Contact us today at service@kaihancnc.com to discuss your project and discover how our expertise in customized medical device components can accelerate your product development process.

References

1. Johnson, A. R., & Smith, B. T. (2021). Precision Engineering in Medical Device Manufacturing: Advancements and Challenges. Journal of Biomedical Engineering, 45(3), 287-302.

2. Lee, S. H., & Park, J. Y. (2020). From Concept to Clinical Use: The Journey of Custom Surgical Instruments. Medical Device Innovation, 18(2), 112-128.

3. Garcia, M. L., & Thompson, R. K. (2022). Regulatory Pathways for Novel Medical Devices: A Comprehensive Guide. Healthcare Regulatory Affairs, 33(4), 401-418.

4. Chen, X., & Wilson, D. R. (2019). Materials Science in Surgical Tool Development: Balancing Performance and Biocompatibility. Advanced Materials for Medical Applications, 27(1), 56-73.

5. Murphy, E. J., & O'Sullivan, K. P. (2023). Quality Control in Medical Device Manufacturing: Ensuring Safety and Efficacy. Quality Assurance in Healthcare, 41(2), 189-205.

6. Patel, N. V., & Roberts, L. M. (2021). Post-Market Surveillance of Medical Devices: Challenges and Opportunities in the Digital Age. Journal of Patient Safety and Risk Management, 36(3), 245-260.