Comparing advanced composites and engineering plastics

Advanced composites and designing plastics have developed as game-changers in the mechanical technology industry, advertising interesting properties that outperform conventional materials like aluminum. These inventive materials are reshaping the way we approach the plan and manufacture of robot components.

Advanced Composites: Strength Meets Lightness

Carbon fiber strengthened polymers (CFRP) and glass fiber strengthened polymers (GFRP) are at the bleeding edge of progressed composites utilized in Robot Mechanical Parts, offering superior strength, reduced weight, and enhanced performance for advanced robotic systems. These materials offer an remarkable strength-to-weight proportion, making them perfect for applications where minimizing mass is significant without compromising basic astuteness. For occasion, robot arm sections made from CFRP can be up to 50% lighter than their aluminum partners whereas keeping up comparable strength.

Moreover, progressed composites give great vibration damping properties, which is especially advantageous for high-precision operations. This characteristic makes a difference in diminishing the settling time after fast developments, subsequently improving the in general exactness and speed of mechanical systems.

Engineering Plastics: Versatility and Cost-Effectiveness

Engineering plastics such as polyetheretherketone (PEEK), polyamide (PA), and polyoxymethylene (POM) offer a balance between performance and cost-effectiveness. These materials exhibit high strength, low friction, and excellent chemical resistance, making them suitable for a wide range of robotic applications.

PEEK, in particular, has gained popularity in the production of gears, bearings, and other wear-resistant components due to its exceptional mechanical properties and ability to withstand high temperatures. Its self-lubricating nature reduces the need for additional lubrication, simplifying maintenance and extending the lifespan of robotic parts.

When comparing advanced composites to engineering plastics, several factors come into play:

- Weight: Advanced composites generally offer superior weight savings.

- Cost: Engineering plastics are often more cost-effective for large-scale production.

- Customization: Composites allow for greater design flexibility and tailored properties.

- Environmental resistance: Some engineering plastics outperform composites in harsh chemical environments.

The choice between these materials ultimately depends on the specific requirements of the robotic application, balancing factors such as performance, cost, and manufacturing complexity.

Selecting materials for wear resistance and durability

In the realm of robotics, wear resistance and durability are paramount considerations when selecting materials for precision robot mechanical parts. The constant motion and interaction between components can lead to significant wear over time, potentially compromising the robot's accuracy and longevity. Therefore, choosing materials that can withstand these challenges is crucial for ensuring the sustained performance of industrial robots.

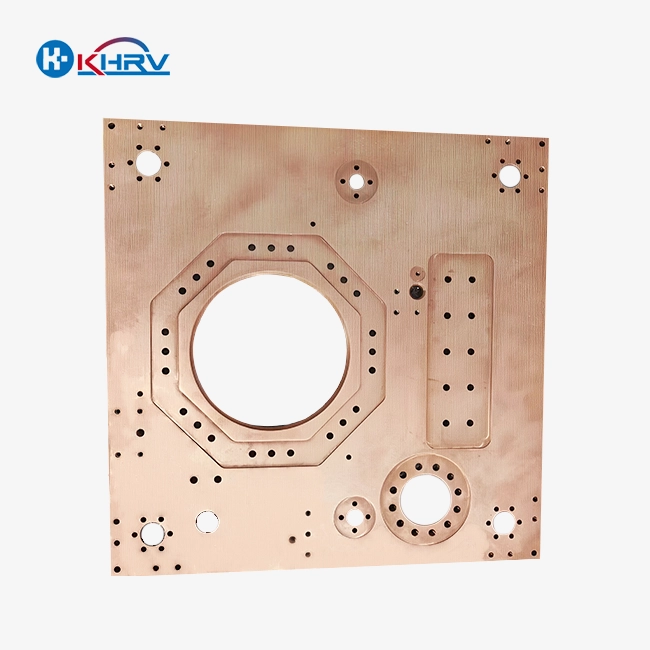

High-Performance Metals and Alloys

While aluminum remains a popular choice, other metals and alloys offer superior wear resistance for critical robotic components:

- Stainless Steel: Grades like 17-4 PH and 440C provide excellent corrosion resistance and hardness, making them ideal for bearings and shafts in robotic joints.

- Titanium Alloys: Known for their high strength-to-weight ratio and corrosion resistance, titanium alloys are perfect for applications requiring both durability and lightness.

- Nickel-based Superalloys: These materials offer exceptional strength and wear resistance at high temperatures, suitable for robots operating in extreme environments.

The selection of these materials depends on factors such as the specific wear mechanisms involved, operating temperatures, and environmental conditions.

Surface Treatments and Coatings

Enhancing the wear resistance of robotic parts often involves the application of specialized surface treatments and coatings:

- Nitriding: This process increases the surface hardness of steels, significantly improving wear resistance.

- Diamond-Like Carbon (DLC) Coatings: These ultra-hard coatings provide excellent wear resistance and low friction, ideal for gears and bearings.

- Ceramic Coatings: Materials like alumina and zirconia offer superior hardness and chemical inertness, protecting parts in abrasive or corrosive environments.

By carefully selecting base materials and applying appropriate surface treatments, engineers can create robotic components that maintain their precision and functionality over extended periods of operation, even under challenging conditions.

How does material choice impact machining strategy and cost?

The selection of materials for industrial robot parts significantly influences both the machining strategy and overall production costs. Understanding these impacts is crucial for optimizing the manufacturing process and ensuring cost-effectiveness without compromising on quality.

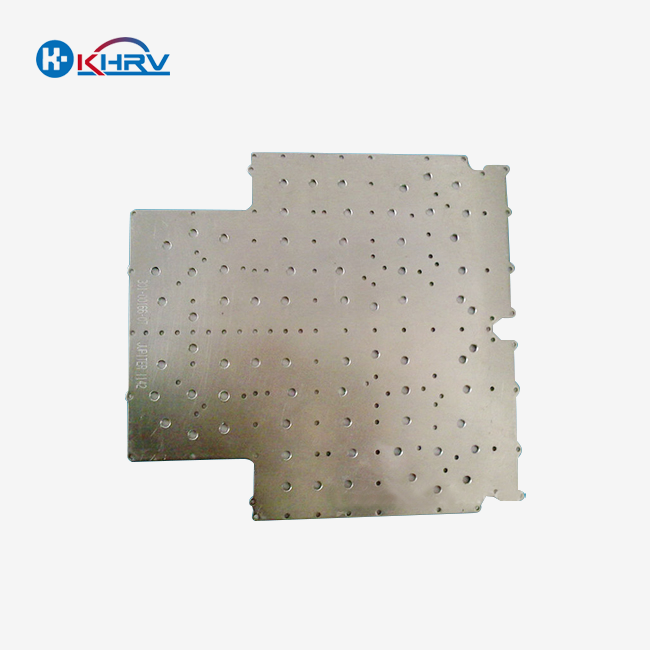

Machining Considerations for Different Materials

Different materials require varying machining approaches:

- Aluminum: Generally easy to machine, allowing for high cutting speeds and feed rates.

- Advanced Composites: Often require specialized tooling and controlled cutting parameters to prevent delamination or fiber pullout.

- Engineering Plastics: May need specific cutting tools and cooling strategies to prevent melting or deformation during machining.

- High-Performance Metals: Often necessitate advanced cutting tools and slower machining speeds, increasing processing time.

These considerations directly impact production efficiency and tool life, which in turn affect manufacturing costs.

Cost Implications of Material Selection

The choice of material influences costs in several ways:

- Raw Material Costs: Advanced materials like titanium alloys or high-performance composites are generally more expensive than traditional metals.

- Tooling Costs: Harder materials may require more frequent tool replacements or specialized cutting tools, increasing overall tooling expenses.

- Processing Time: Materials that are difficult to machine increase production time, potentially leading to higher labor and machine operation costs.

- Post-Processing Requirements: Some materials may need additional treatments or finishing processes, adding to the overall production cost.

However, it's important to consider the long-term benefits of using high-performance materials. While initial costs may be higher, the improved durability and performance of the final product can lead to reduced maintenance needs and longer service life, potentially offering better value over time.

Balancing Performance and Cost

Achieving the optimal balance between performance and cost requires a holistic approach:

- Design Optimization: Utilizing advanced design techniques like topology optimization can minimize material use while maintaining performance.

- Material Substitution: In some cases, using a combination of materials or finding cost-effective alternatives that meet performance requirements can reduce overall costs.

- Process Innovation: Investing in advanced manufacturing technologies, such as additive manufacturing for complex geometries, can sometimes offset higher material costs through reduced waste and processing time.

By carefully considering these factors, manufacturers can develop strategies that maximize the performance of robotic components while keeping production costs under control.

Conclusion

The evolution of materials for robot mechanical parts extends far beyond traditional choices like aluminum. Advanced composites, engineering plastics, and high-performance metals offer exciting possibilities for enhancing the capabilities of industrial robots. By carefully considering factors such as strength-to-weight ratio, wear resistance, and machining requirements, engineers can select materials that optimize both performance and cost-effectiveness.

As the mechanical autonomy industry proceeds to development, the significance of fabric choice in accomplishing accuracy, solidness, and proficiency cannot be exaggerated. The future of mechanical autonomy lies in the imaginative utilize of these progressed materials, pushing the boundaries of what's conceivable in mechanization and manufacturing. Partnering with a trusted Robot Mechanical Parts supplier ensures access to high-quality, durable components that drive innovation and performance in next-generation robotic systems.

Are you looking to raise the execution of your mechanical frameworks with cutting-edge materials and precision-engineered components? Wuxi Kaihan Innovation Co., Ltd. specializes in the improvement and generation of high-performance parts for manufactured insights hardware and computerized accuracy apparatus. Our group of specialists, with broad involvement in exactness CNC machining and shape plan, is prepared to offer assistance you select the perfect materials and fabricating forms for your particular needs.

Take advantage of our competitive estimating, ISO9001:2006 certified quality administration framework, and state-of-the-art fabricating offices. Whether you require OEM preparing of key accuracy apparatus components or cross-border semi-finishing arrangements, we have the ability to convey. Contact us nowadays at service@kaihancnc.com to talk about how we can back your mechanical technology ventures with our progressed fabric choice and fabricating capabilities.

References

1. Smith, J. D., & Johnson, R. A. (2022). Advanced Materials in Robotics: A Comprehensive Review. Journal of Robotic Engineering, 15(3), 245-260.

2. Lee, K. H., et al. (2021). Comparative Analysis of Composite Materials for High-Performance Robot Actuators. Robotics and Autonomous Systems, 142, 103812.

3. Chen, X., & Zhang, Y. (2023). Wear-Resistant Materials for Industrial Robot Applications: Current Status and Future Prospects. Wear, 502-503, 204080.

4. Patel, N., & Brown, S. (2022). Cost-Effective Manufacturing Strategies for Advanced Robotic Components. International Journal of Advanced Manufacturing Technology, 118(5), 1565-1580.

5. Williams, E. M., et al. (2023). Material Selection Optimization for Robotic End Effectors: A Multi-Criteria Decision-Making Approach. Materials & Design, 224, 111374.

6. Takahashi, H., & Garcia, C. (2021). Surface Engineering Techniques for Enhancing Durability of Robot Mechanical Parts. Surface and Coatings Technology, 409, 126907.