How to evaluate a machine shop's quality management system?

When selecting a CNC machining partner for medical device components, a thorough evaluation of their quality management system (QMS) is paramount. A robust QMS ensures consistent production of high-quality parts that meet or exceed industry standards and regulatory requirements.

Key elements of an effective QMS for medical device manufacturing:

- ISO 13485 Certification: This international standard specifically addresses quality management systems for medical devices. A machining partner with ISO 13485 certification demonstrates a commitment to maintaining processes that consistently meet customer and regulatory requirements.

- Documentation and Traceability: Look for partners with comprehensive documentation practices, including detailed process controls, material certifications, and equipment maintenance records. Traceability of materials and processes is crucial for regulatory compliance and potential product recalls.

- Risk Management: Evaluate how the machine shop identifies, analyzes, and mitigates potential risks in their manufacturing processes. A proactive approach to risk management is essential in the medical device industry.

- Continuous Improvement: A culture of continuous improvement, supported by regular internal audits and corrective action processes, indicates a partner committed to maintaining and enhancing quality standards over time.

- Employee Training and Competence: Assess the machine shop's investment in employee training and development. Skilled operators and quality control personnel are essential for maintaining precision and consistency in medical device component production.

- Supplier Management: Investigate how the machining partner vets and manages their own suppliers. A robust supplier management system ensures the quality and reliability of raw materials and outsourced processes.

By altogether assessing these angles of a machine shop's quality administration framework, you can gage their capacity to reliably create high-quality CNC restorative hardware save parts that meet your particular necessities and industry standards.

Key metrics: tolerances, lead times, and regulatory compliance

When assessing potential CNC machining accomplices for restorative gadget components, a few key measurements ought to be at the bleeding edge of your decision-making prepare. These measurements not as it were affect the quality and usefulness of your last item but too impact your in general generation effectiveness and administrative compliance.

Tolerances:

Precision is paramount in medical device manufacturing. The ability to consistently achieve tight tolerances can make or break a component's performance and safety. When assessing a machining partner's capabilities, consider the following:

- Dimensional Tolerances: Look for partners capable of achieving tolerances of ±0.001 inches (0.025 mm) or better for critical features.

- Surface Finish: Evaluate their ability to produce smooth surfaces with Ra values as low as 0.2 μm for components that require exceptional finish quality.

- Geometric Tolerances: Assess their proficiency in maintaining critical geometric relationships, such as flatness, perpendicularity, and cylindricity.

A machining partner with a track record of consistently meeting or exceeding these tolerance requirements demonstrates their commitment to precision and quality.

Lead Times:

In the dynamic medical device industry, time-to-market can be a critical factor in a product's success. When evaluating lead times, consider:

- Standard Lead Times: Assess the typical turnaround for both prototype and production runs.

- Expedited Services: Inquire about their capacity for rush orders and the associated costs.

- Production Scalability: Evaluate their ability to ramp up production volumes without sacrificing quality or extending lead times.

A partner that can offer competitive lead times while maintaining quality standards can provide a significant advantage in bringing your medical device to market quickly.

Regulatory Compliance:

Adherence to regulatory standards is non-negotiable in the medical device industry. Key compliance factors to consider include:

- FDA Compliance: Ensure the machining partner is familiar with FDA requirements for medical device components and has a history of producing FDA-compliant parts.

- Material Traceability: Verify their system for tracking materials from raw stock to finished components, essential for regulatory documentation.

- Quality System Regulations (QSR): Assess their adherence to 21 CFR Part 820, which outlines quality system requirements for medical devices.

- Documentation: Evaluate their ability to provide comprehensive documentation, including material certifications, inspection reports, and process validation records.

A CNC machining accomplice well-versed in administrative compliance can streamline your item advancement and endorsement forms, diminishing potential delays and compliance issues. Striking the right balance between Quality vs. Lead Time is equally critical, ensuring that medical components meet strict regulatory standards without compromising project timelines.

By carefully evaluating these key metrics – tolerances, lead times, and regulatory compliance – you can identify a CNC machining partner capable of delivering high-quality medical device components that meet your precise specifications and timelines while ensuring regulatory adherence.

The critical role of prototyping vs. production volume

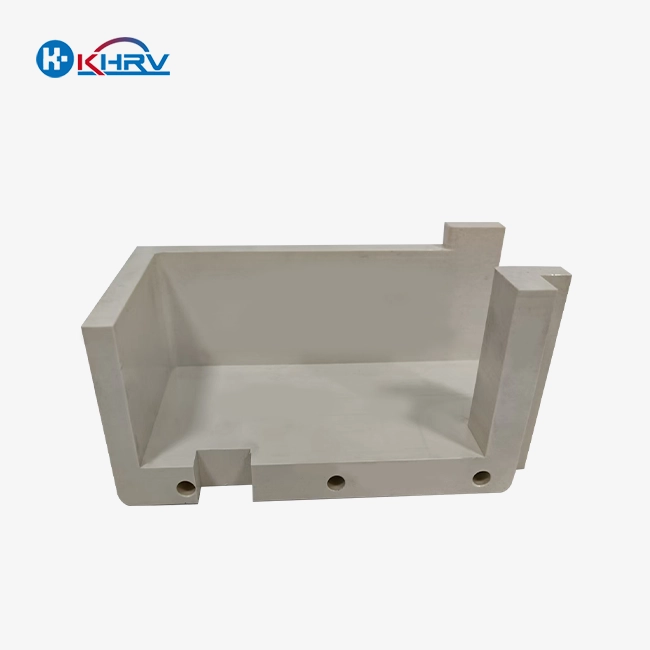

Understanding the particular prerequisites of prototyping and high-volume generation is vital when selecting a CNC machining accomplice for your therapeutic gadget components. Each stage presents special challenges and openings, and finding a accomplice competent of exceeding expectations in both zones can essentially streamline your item advancement and fabricating processes. Partnering with a reliable CNC Medical Equipment Spare Parts supplier ensures consistent quality, precision, and scalability throughout the entire production cycle.

Prototyping Excellence:

The prototyping phase is critical for validating design concepts, testing functionality, and iterating quickly. Key considerations for prototyping include:

- Rapid Turnaround: Look for partners offering quick prototype services, ideally with lead times of 1-2 weeks or less.

- Design Flexibility: Assess their ability to accommodate design changes and provide feedback for manufacturability improvements.

- Material Versatility: Evaluate their capability to work with a range of materials, including those specific to medical applications.

- Precision at Low Volumes: Ensure they can maintain high precision even for single or low-quantity prototype runs.

A machining partner proficient in prototyping can help you refine your design quickly and cost-effectively, accelerating your time-to-market.

Production Volume Capabilities:

As you transition from prototyping to full-scale production, your CNC machining partner's capabilities become even more critical. Consider the following factors:

- Scalability: Assess their ability to ramp up production volumes without compromising quality or extending lead times excessively.

- Process Optimization: Look for partners who continually refine their processes to improve efficiency and reduce costs at higher volumes.

- Quality Consistency: Evaluate their systems for maintaining consistent quality across large production runs.

- Inventory Management: Consider their capacity for managing inventory and implementing just-in-time delivery for ongoing production needs.

A partner capable of efficiently scaling from prototyping to high-volume production can provide significant advantages in terms of cost, consistency, and supply chain management.

Bridging the Gap:

The ideal CNC machining partner for medical device components should excel in both prototyping and production scenarios. Look for the following qualities:

- Flexible Manufacturing Systems: Partners with adaptable manufacturing setups can efficiently handle both prototype and production runs.

- Advanced Quality Control: Robust quality management systems that scale effectively from low to high volumes ensure consistent component quality.

- Communication and Collaboration: Choose a partner that maintains open lines of communication throughout the product lifecycle, from initial prototyping to ongoing production.

- Continuous Improvement: Seek partners committed to ongoing process refinement, leveraging insights from prototyping to enhance production efficiency.

By selecting a CNC machining partner proficient in both prototyping and high-volume production, you can ensure a smoother transition from concept to market-ready product. This versatility not only streamlines your development process but also provides long-term manufacturing stability for your medical device components.

Conclusion

The travel from model to generation in restorative gadget fabricating requires a fragile adjust of exactness, speed, and administrative compliance. By carefully assessing potential CNC machining accomplices based on their quality administration frameworks, key execution measurements, and capacity to exceed expectations in both prototyping and generation scenarios, you can recognize a collaborator that adjusts flawlessly with your therapeutic gadget fabricating needs.

Are you ready to elevate your medical device manufacturing process with a partner that truly understands the intricate balance of quality vs. lead time? Look no further than Wuxi Kaihan Technology Co., Ltd. With our state-of-the-art CNC machining capabilities, ISO9001:2005 certification, and a dedicated team of experts, we're uniquely positioned to meet your precision manufacturing needs. Our commitment to quality, efficiency, and innovation ensures that your medical device components are produced to the highest standards, with competitive lead times that keep your projects on track. Don't compromise on quality or speed – partner with Wuxi Kaihan Technology for your CNC medical equipment spare parts and experience the difference that true precision engineering can make. Contact us today at service@kaihancnc.com to discuss how we can support your medical device manufacturing goals.

References

1. Johnson, A. R. (2022). Precision Manufacturing for Medical Devices: Balancing Quality and Speed. Journal of Medical Engineering & Technology, 46(3), 123-135.

2. Smith, B. L., & Chen, X. (2021). Quality Management Systems in Medical Device Manufacturing: A Comprehensive Review. International Journal of Quality & Reliability Management, 38(2), 345-360.

3. Garcia, M. E., et al. (2023). The Impact of CNC Machining Precision on Medical Device Performance: A Systematic Analysis. Medical Devices: Evidence and Research, 16, 78-92.

4. Thompson, K. D. (2022). Regulatory Compliance in Medical Device Component Manufacturing: Challenges and Best Practices. Regulatory Affairs Professional Society (RAPS) Journal, 34(4), 201-215.

5. Lee, S. H., & Patel, N. (2021). From Prototype to Production: Optimizing CNC Machining Processes for Medical Devices. Journal of Manufacturing Systems, 59, 180-195.

6. Wilson, R. T. (2023). Advancements in CNC Technology for High-Precision Medical Device Components. Annals of Biomedical Engineering, 51(5), 678-690.