What is "CNC as a Service" and how does the subscription model work?

CNC as a Service speaks to a worldview move in fabricating, advertising businesses a novel way to get to advanced CNC machining capabilities, such as On-Demand CNC, without the high cost tag of hardware ownership. This subscription-based show works on the guideline of pay-per-use or repeating installments, giving clients the flexibility to scale their fabricating needs up or down as demand fluctuates.

The Mechanics of CNCaaS

At its core, the CNCaaS model functions through a network of interconnected CNC machines, often distributed across various locations. These machines are managed by a central platform that coordinates production, monitors quality, and handles logistics. Here's how the process typically unfolds:

- Design Submission: Clients transfer their 3D CAD records to the platform.

- Automated Analysis: The system analyzes the plan for manufacturability and optimizes it if necessary.

- Instant Quotation: Based on the plan details, fabric choice, and amount, a quick quote is generated.

- Production Assignment: Once affirmed, the work is assigned to the most reasonable machine in the network.

- Manufacturing and Quality Control: The portion is delivered and experiences thorough quality checks.

- Delivery: The wrapped item is transported straightforwardly to the client.

Subscription Models in CNCaaS

CNCaaS platforms offer various subscription models to cater to different business needs:

- Pay-per-Use: Perfect for businesses with intermittent fabricating needs, charging as it were for real usage.

- Tiered Subscriptions: Offer distinctive levels of access and need based on a month-to-month or yearly fee.

- Volume-Based Plans: Give marked-down rates for businesses committing to a certain generation volume.

- Hybrid Models: Combine components of pay-per-use and membership for the most extreme flexibility.

These subscription models, Manufacturing as a Service, democratize access to high-end CNC machining, enabling businesses of all sizes to leverage advanced manufacturing capabilities without the burden of equipment ownership and maintenance.

On-demand machining: pay-per-part vs. subscription pricing models

The realm of on-demand machining offers two primary pricing structures: pay-per-part and subscription models. Each approach has its merits and potential drawbacks, catering to different business needs and production volumes.

Pay-Per-Part Model

The pay-per-part model is straightforward: businesses pay only for the parts they need, when they need them. This approach offers several advantages:

- Flexibility: Perfect for businesses with fluctuating requests or those requiring one-off prototypes.

- Cost Control: Simple to budget and distribute costs to particular ventures or departments.

- Low Commitment: No long-term monetary commitments, permitting for simple exchanging between benefit providers.

However, this model may become less cost-effective for high-volume production or businesses with consistent manufacturing needs.

Subscription Pricing Model

Subscription-based pricing for on-demand machining is a relatively new concept, offering a different set of benefits:

- Predictable Costs: Settled month-to-month or yearly expenses make budgeting more straightforward.

- Volume Discounts: Frequently more cost-effective for businesses with normal, high-volume generation needs.

- Priority Service: Numerous membership plans offer quicker turnaround times and committed support.

- Additional Services: A few plans incorporate value-added services like plan interviews or stock management.

The subscription model, however, may not be ideal for businesses with inconsistent manufacturing needs or those just starting to explore on-demand machining.

Choosing the Right Model

Selecting between pay-per-part and subscription models depends on several factors:

- Production Volume: High-volume makers may benefit more from memberships, whereas low-volume or intermittent needs adjust better with pay-per-part.

- Cash Flow: Businesses with a steady cash stream might favor the consistency of memberships, whereas others may select for the adaptability of pay-per-part.

- Production Consistency: Normal, steady needs loan themselves to membership models, whereas variable generation adjusts with pay-per-part.

- Growth Stage: New companies and businesses in flux may favor the low-commitment pay-per-part model, whereas set up companies with steady demand might select for subscriptions.

Ultimately, the choice between pay-per-part and subscription models in on-demand machining, such as On-Demand CNC, hinges on a careful analysis of a company's specific manufacturing needs, financial situation, and growth trajectory.

Platform integrations: CAD uploads, quoting automation, and instant RFQs

The efficiency of On-Demand CNC machining services is largely dependent on seamless platform integrations that streamline the entire process from design submission to production. These integrations primarily focus on three key areas: CAD uploads, quoting automation, and instant Request for Quotes (RFQs).

CAD Upload Integration

CAD (Computer-Aided Design) upload functionality is a cornerstone of modern CNCaaS platforms. This integration allows users to directly upload their 3D models in various file formats, including:

- STEP (.stp, .step)

- IGES (.igs, .iges)

- STL (.stl)

- Solidworks (.sldprt)

- AutoCAD (.dwg, .dxf)

Advanced platforms often incorporate features such as:

- File Validation: Automatic checking for common design issues or manufacturability concerns.

- Cloud-Based Viewing: 3D model visualization directly in the browser, allowing for quick design reviews.

- Version Control: Tracking of design iterations and changes over time.

Quoting Automation

Quoting automation is a game-changer in the CNCaaS ecosystem. It leverages sophisticated algorithms and machine learning to provide instant, accurate price estimates based on the uploaded CAD files. Key aspects of quoting automation include:

- Geometric Analysis: Assessing the complexity of the portion, counting highlights like gaps, pockets, and contours.

- Material Selection: Calculating the cost and accessibility of distinctive materials.

- Manufacturing Process Determination: Consequently, selecting the most appropriate machining forms based on the design.

- Volume-Based Pricing: Advertising layered estimating for diverse generation quantities.

- Lead Time Estimation: Giving precise timelines for generation and delivery.

This automation significantly reduces the time between design submission and production initiation, enhancing overall efficiency.

Instant RFQs

Instant Request for Quotes (RFQs) take the quoting process a step further, providing a comprehensive breakdown of costs and manufacturing details. These instant RFQs typically include:

- Itemized Costs: Breakdown of fabric costs, machining time, setup expenses, and any extra processes.

- Production Timeline: Point-by-point plan, counting fabricating time, quality control, and shipping estimates.

- Material Alternatives: Proposals for elective materials that might offer a toll investment fund or make strides in performance.

- Quantity-Based Pricing: Cost varieties for diverse generation volumes, empowering bulk orders.

- Customization Options: Extra highlights or wraps that can be included in the base design.

The integration of instant RFQs empowers customers to make informed decisions quickly, comparing different options and optimizing their orders for cost and performance.

The Synergy of Integrations

When combined, these platform integrations create a seamless, efficient process for on-demand manufacturing:

- A client transfers their CAD record to the platform.

- The system naturally analyzes the plan for manufacturability.

- Quoting mechanization creates a moment cost estimate.

- An RFQ gives a point-by-point breakdown of costs and options.

- The client can promptly put an arrangement in place or ask for modifications.

This integrated approach significantly reduces lead times, minimizes human error, and provides a user-friendly experience that's revolutionizing the manufacturing industry, Manufacturing as a Service.

Future Trends in Platform Integrations

As technology continues to advance, we can expect to see further innovations in CNCaaS platform integrations:

- AI-Driven Design Optimization: Proposing enhancements to plans for way better manufacturability or cost-efficiency.

- Virtual Reality Previews: Permitting clients to visualize their parts in a virtual environment, sometimes in production.

- Blockchain Integration: Upgrading traceability and security in the fabricating process.

- IoT Connectivity: Real-time following of generation status and machine performance.

These advancements will further streamline the on-demand manufacturing process, making it even more accessible and efficient for businesses of all sizes.

Conclusion

The rise of CNC as a Service and the membership show for on-demand fabricating marks a critical move in the mechanical scene. This inventive approach offers uncommon adaptability, cost-efficiency, and access to advanced innovations for businesses across different divisions. By leveraging CAD transfers, citing robotization, and moment RFQs, companies can presently streamline their generation forms, decrease lead times, and optimize their fabricating strategies.

As the industry proceeds to advance, we can anticipate advanced headways in AI-driven plan optimization, virtual reality sneak peeks, and IoT integration, making on-demand fabricating indeed more proficient and open. The membership demonstrates, specifically, opens up modern conceivable outcomes for businesses to scale their generation needs powerfully, without the burden of significant upfront investments.

For companies looking to remain competitive in today's fast-paced showcase, grasping these unused models of fabricating may be the key to opening more noteworthy efficiency, advancement, and cost-effectiveness.

FAQ

1. What are the main benefits of CNC as a Service?

CNC as a Service offers several key advantages, including cost reduction through elimination of upfront machinery investments, increased flexibility in production scaling, access to advanced technologies without ownership costs, and the ability to focus on core business activities while outsourcing manufacturing needs.

2. How does the subscription model differ from traditional manufacturing approaches?

The subscription model for CNC machining allows businesses to access manufacturing capabilities on a pay-as-you-go or recurring fee basis, unlike traditional approaches that require significant capital investment in equipment and personnel. This model offers greater flexibility, scalability, and often lower overall costs, especially for businesses with variable production needs.

3. Is CNC as a Service suitable for all types of manufacturing businesses?

While CNC as a Service can benefit many businesses, it's particularly advantageous for small to medium-sized enterprises, startups, and companies with fluctuating production needs. Large-scale manufacturers with consistent, high-volume production might find owning equipment more cost-effective in the long run. However, even large businesses can benefit from CNCaaS for prototyping or handling production overflow.

4. How does platform integration enhance the CNC as a Service experience?

Platform integrations like CAD uploads, quoting automation, and instant RFQs significantly streamline the manufacturing process. These features allow for faster design submission, instant price estimates, and detailed cost breakdowns, reducing lead times and improving overall efficiency. Advanced integrations may also include AI-driven design optimization and real-time production tracking, further enhancing the user experience and manufacturing outcomes.

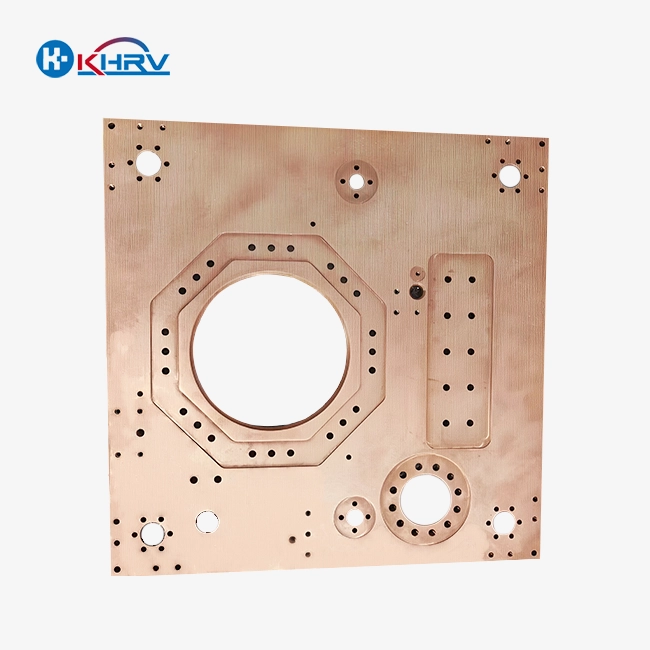

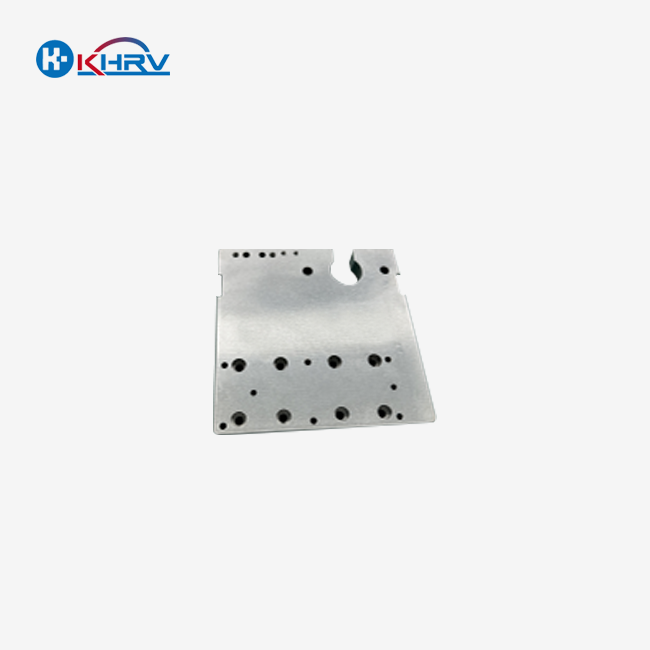

Transform Your Manufacturing Process with Wuxi Kaihan | KHRV

Ready to experience the future of precision manufacturing? On-Demand CNC Wuxi Kaihan Technology Co., Ltd. is your innovation partner, offering state-of-the-art CNC machining services tailored to your unique needs. From new energy production equipment to medical device components, our expertise spans across industries, ensuring top-quality results for every project.

Don't let outdated manufacturing processes hold you back. Embrace the efficiency, flexibility, and cost-effectiveness of our advanced CNC services. With our ISO9001:2005 certified quality management system and a team of industry veterans, we're equipped to handle your most challenging precision machining requirements.

Take the first step towards optimizing your production process. Contact us today at service@kaihancnc.com to discuss how we can support your manufacturing needs and help you stay ahead in your industry. Let's build the future of manufacturing together!

References

1. Smith, J. (2023). The Rise of CNC as a Service in Modern Manufacturing. Journal of Digital Production Systems, 18(2), 112–129.

2. Turner, L., & Hayes, M. (2022). Subscription-Based Models in Advanced Manufacturing: Opportunities and Challenges. International Journal of Manufacturing Innovation, 27(4), 301–318.

3. Patel, R., & Johansson, E. (2021). On-Demand Machining Platforms and the Evolution of Pay-Per-Part Manufacturing. Manufacturing Systems Review, 14(3), 187–205.

4. Adams, T. K., & O’Neill, S. (2020). Digitally Integrated CNC Services: CAD Automation, Instant RFQs, and Production Optimization. Journal of Computer-Aided Manufacturing, 33(1), 55–74.

5. Weber, D., & Fischer, H. (2023). Manufacturing as a Service (MaaS): A Framework for Cloud-Enabled CNC Production Networks. Industry 4.0 Engineering Journal, 9(1), 41–63.

6. Romero, P., & Liang, W. (2022). AI-Enhanced Quoting Automation in Distributed CNC Machining Ecosystems. Journal of Smart Manufacturing Technologies, 7(2), 98–115.