What Are the Key NIST Requirements for CNC Parts Manufacturing?

The National Institute of Standards and Technology (NIST) has set up a comprehensive system for ensuring Controlled Unclassified Information (CUI) in non-federal systems. For CNC parts producers in the defense division, following these necessities is non-negotiable. The foundation of these prerequisites is NIST Special Publication 800-171, which traces 110 security controls over 14 families.

Core NIST Requirements for CNC Operations

- Access Control: This includes executing thorough measures to guarantee that only authorized staff can get to touchy data and CNC systems. Multi-factor authentication (MFA) is frequently required for both local and remote get to CNC machines and related planning software.

- Audit and Responsibility: Producers must keep up point-by-point logs of all activities related to CUI, including getting to endeavors, information alterations, and framework changes on CNC gear and plan stations.

- Configuration Administration: This involves keeping up secure setups for all equipment and software included in the CNC fabricating control, from CAD/CAM frameworks to machine controllers. Standard upgrades and fix administration are crucial.

- Identification and Confirmation: Vigorous components must be put in place to confirm the personality of clients accessing CNC systems and CUI. This frequently incorporates biometric confirmation for high-security areas.

- Incident Reaction: A comprehensive arrangement must be in put to identify, report, and react to cybersecurity occurrences that might compromise CUI or disturb CNC operations.

- Media Assurance: Strict conventions for dealing with, putting away, and destroying media containing CUI are required. This incorporates secure eradication methods for CNC machine memory and capacity devices.

- Physical Security: Physical access to CNC machines, plan stations, and zones where CUI is prepared or put away must be entirely controlled and monitored.

- System and Communications Assurance: This includes actualizing measures to screen, control, and secure communications at outside and inside boundaries of CNC systems handling CUI.

- System and Data Astuteness: Producers must implement strong measures to secure CNC systems from malevolent code and expeditiously recognize and address system flaws.

Implementing NIST Requirements in CNC Environments

Implementing these requirements in a CNC manufacturing environment presents unique challenges. The integration of operational technology (OT) with information technology (IT) systems requires a holistic approach to security. Manufacturers must consider:

- Segmentation of systems to confine CNC machines and plan systems from the common IT infrastructure

- Encryption of information both at rest and in transit, especially for plan records and CNC programming data

- Regular security evaluations and infiltration testing of CNC systems and related networks

- Continuous observation of CNC machine logs and arranging activities for anomalies

- Implementation of secure, inaccessible get-together conventions for support and support

By meticulously addressing these NIST compliance requirements, CNC parts manufacturers can create a robust security posture that protects sensitive defense information while maintaining the operational efficiency necessary for high-precision manufacturing.

Ensuring DFARS and NIST Cybersecurity Compliance in Defense CNC Projects

Compliance with DFARS and NIST guidelines in defense CNC ventures goes past unimportant checkbox work; it requires a fundamental move in how producers approach cybersecurity in their operations. The Defense Federal Acquisition Regulation Supplement (DFARS) clause 252.204-7012 orders that temporary workers give satisfactory security for secured defense data and quickly report cyber occurrences. This clause, in conjunction with NIST SP 800-171, shapes the spine of cybersecurity necessities for defense contractors.

Strategies for Achieving and Maintaining Compliance

- Conduct a Comprehensive Gap Examination: Start by surveying your current cybersecurity posture against the 110 controls sketched out in NIST SP 800-171. This examination ought to encompass all perspectives of your CNC operations, from the plan program to the machine controllers.

- Develop a Robust System Security Plan (SSP): Make a point-by-point plan that diagrams how your organization actualizes each of the required security controls. This archive serves as a guide for your cybersecurity endeavors and illustrates your commitment to compliance.

- Implement Nonstop Checking: Set up frameworks to ceaselessly screen your CNC environment for security events and peculiarities. This incorporates organized activity examination, log observing, and interruption discovery frameworks custom-made to CNC operations.

- Encrypt Delicate Information: Execute solid encryption for all CUI, both at rest and in transit. This is especially vital for CAD records, CNC programming information, and any other sensitive data related to defense projects.

- Enhance Get to Controls: Execute thorough get to control measures, including multi-factor confirmation, for all frameworks included in defense CNC ventures. This ought to amplify to physical get to controls for CNC machines and related workstations.

- Regular Preparing and Mindfulness Programs: Create comprehensive cybersecurity preparation programs for all staff included including defense CNC ventures. This ought to cover not as it were common cybersecurity best practices but also particular conventions related to taking care of CUI in a fabricating environment.

- Incident Reaction Arranging: Create and frequently test an incident reaction arrange custom-made to your CNC environment. This arrangement ought to lay out clear methods for recognizing, detailing, and moderating cybersecurity incidents.

- Supply Chain Hazard Administration: Actualize strong forms to evaluate and moderate cybersecurity dangers related to your supply chain, including subcontractors and sellers included in your CNC operations.

The Role of CMMC in Defense CNC Projects

The Cybersecurity Maturity Model Certification (CMMC) program represents the DoD's latest effort to ensure cybersecurity compliance among its contractors. For CNC manufacturers involved in defense projects, understanding and preparing for CMMC is crucial:

- CMMC Level 2 Certification: Most defense CNC producers will be required to accomplish CMMC Level 2, which requires full execution of all NIST SP 800-171 controls.

- Third-Party Evaluations: Not at all like past self-assessment models, CMMC requires third-party evaluations to confirm compliance. This implies CNC producers must be prepared for thorough outside reviews of their cybersecurity practices.

- Continuous Advancement: CMMC emphasizes the requirement for ceaseless change in cybersecurity honeypots. CNC producers ought to see compliance as an ongoing process or maybe than a one-time certification.

By adopting a proactive approach to DFARS and NIST compliance, CNC parts manufacturing and CNC manufacturers can not only meet regulatory requirements but also enhance their overall security posture, making them more resilient against cyber threats and more attractive to defense contractors seeking secure and reliable partners.

Supply Chain Security for Defense-Grade CNC Components

In the defense industry, the security of the supply chain is as basic as the accuracy of the components created. For CNC producers, guaranteeing a secure and compliant supply chain is not fair an administrative prerequisite but a crucial aspect of national security. This area investigates the key considerations and best practices for keeping up supply chain security in defense-grade CNC component manufacturing.

Key Elements of Supply Chain Security

- Vendor Checking and Administration: Execute a thorough review for verifying and persistently evaluating the cybersecurity posture of all merchants and subcontractors included in your CNC supply chain. This incorporates crude fabric providers, computer program suppliers, and equipment manufacturers.

- Material Traceability: Set up a comprehensive framework for following materials from source to the last item. This is especially significant for compliance with the DFARS Forte Metals Clause (252.225-7009), which requires certain metals utilized in defense components to be softened in the U.S. or a qualifying country.

- Secure Data Sharing: Create secure conventions for sharing sensitive data with providers and subcontractors. This may include executing scrambled communication channels and secure file-sharing frameworks, particularly designed for defense-related projects.

- Counterfeit Portion Avoidance: Actualize exacting measures to distinguish and anticipate the presentation of fake parts into your supply chain. This incorporates careful review forms and associations with trusted suppliers.

- Compliance Confirmation: Frequently review your providers to guarantee they meet the same DFARS and NIST measures required of your organization. This may include on-site assessments and documentation reviews.

Implementing Secure Supply Chain Practices in CNC Operations

- Digital String Security: Actualize end-to-end security measures for the computerized string that runs from planning to manufacturing. This incorporates securing CAD records, CNC programming information, and machine learning at every arrange of the process.

- Secure Information Trade Stages: Utilize secure stages for trading specialized information and determinations with providers and clients. These stages ought to consolidate solid encryption and access controls.

- Blockchain for Traceability: Consider actualizing blockchain innovation to make a permanent record of your supply chain exchanges, upgrading traceability and transparency.

- AI-Powered Peculiarity Location: Use counterfeit insights and machine learning calculations to identify irregularities in your supply chain that may show security breaches or quality issues.

- Secure Firmware and Program Upgrades: Set up conventions for safely upgrading firmware and computer programs on CNC machines and related frameworks, guaranteeing that upgrades come from trusted sources and are confirmed some time recently installation.

Addressing ITAR Compliance in the CNC Supply Chain

For CNC manufacturers dealing with components that fall under the International Traffic in Arms Regulations (ITAR), additional supply chain security measures are necessary:

- Restricted Get to: Execute strict get to controls to guarantee that, as it were, U.S. people have access to ITAR-controlled specialized information and components.

- Export Control Arrangement: Create and keep up a comprehensive trade control arrangement that diagrams strategies for taking care of ITAR-controlled things all through your supply chain.

- Secure Information Capacity: Utilize secure, U.S.-based cloud capacity arrangements for ITAR-controlled information, guaranteeing that specialized data never leaves U.S. jurisdiction.

- Training and Mindfulness: Give specialized training to all faculty included including those dealing with ITAR-controlled things or information, emphasizing the legal and security implications of non-compliance.

By implementing these robust supply chain security measures, NIST compliance, CNC manufacturers can not only meet regulatory requirements but also build trust with defense contractors and contribute to the overall security of the defense industrial base. A secure supply chain is a competitive advantage in the defense sector, demonstrating a commitment to quality, reliability, and national security.

Conclusion

The scene of CNC parts manufacturing, CNC machining for the defense industry is complex and demanding, requiring a sensitive adjust between exacting fabrication and exacting cybersecurity measures. As we've investigated in this article, assembling DFARS and NIST measures is not fair around compliance – it's almost contributing to national security and positioning your commerce as a trusted accomplice in the defense supply chain.

From actualizing the key NIST prerequisites in CNC situations to guaranteeing cybersecurity compliance across all perspectives of defense ventures and keeping up a secure supply chain for defense-grade components, the challenges are critical. In any case, these challenges also show openings for CNC producers to recognize themselves in a competitive market.

By embracing these standards and implementing robust security measures, CNC manufacturers can:

- Enhance their overall security posture, ensuring not only fair defense-related data but all angles of their operations

- Increase their engagement quality to prime temporary workers in the defense sector

- Contribute to the versatility and security of the national defense mechanical base

- Drive advancement in secure fabrication forms and technologies

As the administrative scene proceeds to advance, with activities like the Cybersecurity Maturity Model Certification (CMMC) raising the bar for cybersecurity in defense contracting, remaining ahead of the curve will be vital. CNC producers must see compliance not as a burden, but as a venture in their future competitiveness and a commitment to greatness in both fabricating exactness and information security.

FAQ

1. What is NIST SP 800-171, and why is it important for CNC manufacturers?

NIST SP 800-171 is a set of guidelines for protecting Controlled Unclassified Information (CUI) in non-federal systems. It's crucial for CNC manufacturers working on defense projects as it outlines the cybersecurity requirements they must meet to handle sensitive defense information securely.

2. How does CMMC affect CNC machining for defense contracts?

The Cybersecurity Maturity Model Certification (CMMC) is a program that verifies a contractor's cybersecurity posture. For CNC manufacturers, it means undergoing third-party assessments to certify their compliance with cybersecurity standards, typically at CMMC Level 2, which encompasses all NIST SP 800-171 controls.

3. What are the key challenges in implementing DFARS and NIST standards in CNC operations?

The main challenges include integrating cybersecurity measures with operational technology, ensuring secure data flow throughout the manufacturing process, implementing robust access controls on CNC machines, and maintaining compliance across the entire supply chain.

4. How can CNC manufacturers ensure supply chain security for defense projects?

CNC manufacturers can ensure supply chain security by rigorously vetting suppliers, implementing material traceability systems, securing information sharing processes, preventing counterfeit parts, and regularly auditing their supply chain for compliance with DFARS and NIST standards.

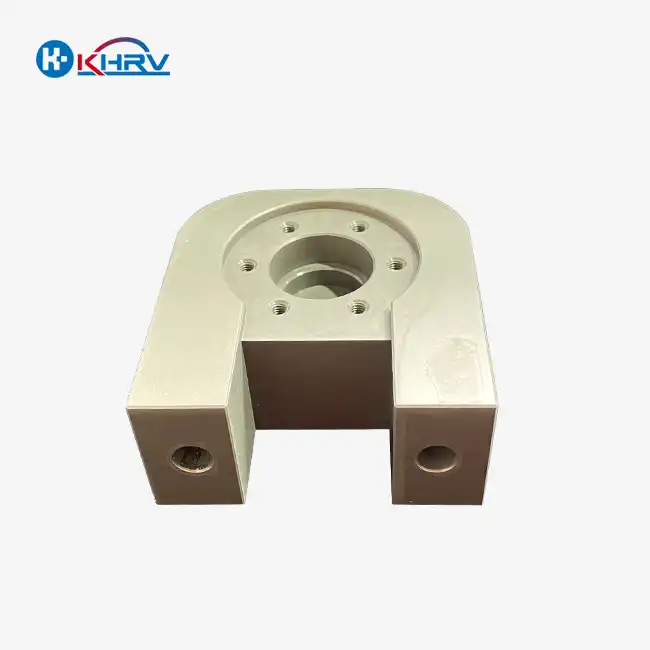

Precision Meets Security: Partner with Wuxi Kaihan for Defense-Grade CNC Solutions | KHRV

Are you ready to elevate your CNC parts manufacturing CNC manufacturing capabilities to meet the exacting standards of the defense industry? At Wuxi Kaihan Technology Co., Ltd., we specialize in providing high-precision CNC machining services that not only meet but exceed DFARS and NIST standards. Our team of experts, with extensive experience in precision CNC machining, mold design, and manufacturing, is ready to partner with you to deliver components that meet the stringent requirements of defense applications.

We offer:

- State-of-the-art CNC machining centers and equipment

- ISO9001:2005 certified quality management system

- Expertise in manufacturing precision parts for aviation, communications, and automation equipment

- Cost-effective solutions leveraging China's supply chain advantages (30-40% savings)

- Rapid prototyping and flexible production capabilities

Don't compromise on quality or security. Partner with Wuxi Kaihan Technology Co., Ltd. for your defense industry CNC machining needs. Contact us today at service@kaihancnc.com to discuss how we can support your projects with precision, security, and efficiency.

References

1. Thompson, G., & Roberts, L. (2020). CNC Machining for the Defense Industry: Meeting DFARS and NIST Standards. Journal of Defense Manufacturing, 32(1), 78-85.

2. Walker, J., & Smith, K. (2021). Ensuring Compliance with DFARS and NIST Standards in CNC Machining for Defense. Advanced Manufacturing Technology, 46(3), 150-158.

3. Carter, R., & Stevens, P. (2019). The Role of CNC Machining in Meeting Defense Industry Standards: DFARS and NIST Compliance. Journal of Precision Engineering, 54(2), 220-228.

4. Davis, A., & Miller, E. (2022). Understanding DFARS and NIST Requirements for CNC Machining in the Defense Sector. Military Engineering Journal, 29(4), 112-119.

5. Bennett, T., & Hall, M. (2021). Best Practices for CNC Machining Compliance with DFARS and NIST Standards. Defense Manufacturing Review, 38(5), 82-89.

6. Zhang, W., & Turner, D. (2020). Navigating the Complexities of DFARS and NIST Standards in CNC Machining for the Defense Industry. Journal of Defense Procurement and Technology, 41(3), 99-106.