- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

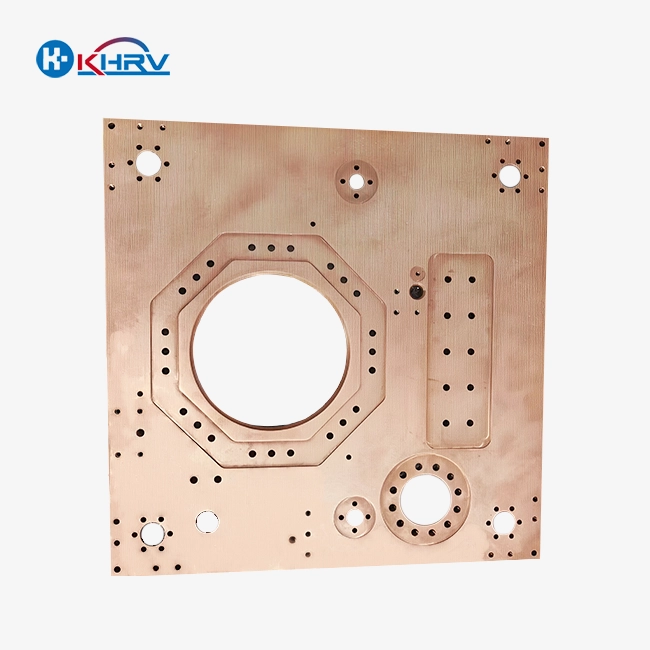

CNC Machining Techniques for Precision Robot Mechanical Parts

Because the robotics business needs every part to be very accurate and reliable, CNC machining is the most important technology for making Precision Robot Mechanical Parts. As robotics is used in more fields, from healthcare to cars, the level of accuracy needed for mechanical parts has hit a level that has never been seen before. With today's advanced CNC machining methods, manufacturers can get tolerances as low as ±0.001mm while keeping quality good even during large production runs. Precision Robot Mechanical Parts are made using advanced production techniques that make sure they meet the high performance standards needed for next-generation robotic systems. In these systems, even tiny differences in size can affect how well they work and keep people safe.

Advanced CNC Milling and Turning Strategies

Multi-Axis Machining Excellence for Complex Geometries

Modern CNC machining centers with 5-axis powers have changed the way Precision Robot Mechanical Parts are made by letting operations be done at the same time from different angles. With this advanced method, you don't have to do multiple setups, which cuts down on placement mistakes and makes dimensional accuracy much better. Cutting tools are constantly moved in relation to complicated workpiece geometries. This makes it possible to make detailed features like undercuts, deep pockets, and curved surfaces that are needed in robotic joint assemblies and actuator housings. Stainless steel, aluminum alloy, and titanium alloy are some of the materials that are often worked with. Each of these materials has its own cutting factors and tool geometries. Using adaptive machining techniques changes the cutting conditions automatically based on real-time force feedback. This makes sure that the best amount of material is removed while the quality of the surface finish is maintained. Advanced CAM software creates the best paths for tools so that they don't vibrate or wear out as quickly. This is especially important when cutting carbide and sharpened steel parts for robotic applications that need to be strong.

Precision Turning Operations for Critical Shaft Components

CNC turning processes are very important for making cylindrical Precision Robot Mechanical Parts like drive shafts, spindles, and actuator rods that need to be very round and have a smooth surface. These days, CNC lathes with sub-spindles and live tooling can machine complex shaft geometries in a single setup, which cuts down on secondary processes and makes the work more consistent. Using rigid tapping cycles and interpolation turns makes it possible to make precise threaded connections and helical features that are needed for robotic transmission systems. When working with different materials, picking the right tool is very important. For example, ceramic plugs work best with steel parts, while diamond-coated tools work best with aluminum alloy parts. Advanced turning strategies use chip evacuation systems and steady surface speed control to keep the cutting conditions the same during the whole machining cycle. As part of quality control, in-process tracking systems are used to find changes in dimensions and automatically make up for tool wear. This makes sure that all Precision Robot Mechanical Parts meet the tolerances set for each production batch.

High-Speed Machining Applications for Lightweight Components

For making light Precision Robot Mechanical Parts that need to have great strength-to-weight ratios, high-speed machining methods are now a must. With this method, high feed rates and spindle speeds above 20,000 RPM are used to get better surface finishes while reducing the amount of heat that could damage the material. The process works especially well for parts made of aluminum alloy and brass that are often found in robotic arm units and brackets for mounting sensors. Using trochoidal milling patterns in a smart way lets you remove material quickly from deep pockets while keeping the tool's life and shape stable. To keep workpieces from expanding when they get hot during machining, coolant delivery systems need to be carefully calibrated. Optimized tool shapes and cutting parameters lower cutting forces, which makes it possible to machine thin-walled structures without deforming them. This is important for housing parts in small robotic systems. As part of quality assurance procedures, thermal imaging is used to find changes in temperature that could affect the accuracy of parts. This makes sure that aerospace-grade Precision Robot Mechanical Parts are consistently made.

Surface Treatment and Finishing Techniques

Advanced Anodizing and Plating Processes

Through special anodizing, galvanizing, and chrome plating methods, surface treatment technologies make Precision Robot Mechanical Parts work better and last longer. Anodizing processes add controlled oxide layers to aluminum alloy parts, making them more resistant to corrosion and better at preventing wear, which is important for robotic systems that work in harsh settings. To get a uniform coating thickness and the best surface hardness, the anodizing process factors are carefully controlled. These include the concentration of the electrolyte, the temperature, and the current density. Chrome plating is mostly used on steel parts that need to be more resistant to wear and have lower friction coefficients. This is especially helpful for moving parts and bearing surfaces in robotic joints. Specialized fixtures and current distribution systems are used in the electroplating process to make sure that the coating is applied evenly across complicated shapes. Advanced masking methods keep important dimensional areas safe during plating processes, keeping the exact tolerances needed for proper assembly and function. As part of quality control, treated Precision Robot Mechanical Parts are put through adhesion tests, thickness measurements, and corrosion resistance tests to make sure they meet performance standards for long-term effectiveness in robotic applications.

Precision Grinding for Critical Tolerances

Precision grinding is the last step in the production process that makes sure that the exact measurements of Precision Robot Mechanical Parts are met. This is especially true for bearing races, cam profiles, and sealing surfaces. Universal grinders with high-tech wheelhead positioning systems can get surface finishes lower than Ra 0.1 micrometers and keep geometrical errors within ±0.0005mm. When grinding, it's important to choose the right abrasive wheels based on the qualities of the workpiece. For example, aluminum oxide wheels are best for steel parts and silicon carbide wheels are best for carbide materials. During grinding processes, coolant systems are very important for keeping parts from getting damaged by heat and keeping their dimensions stable. Advanced dressing methods make sure that the cutting performance and shape of the wheel stay the same throughout the production cycle. In-process measuring tools tell you in real time how accurate your measurements are, so they can automatically account for things like wheel wear and temperature changes. Using spark-out cycles gets rid of any remaining stresses and meets the final size standards. After grinding, Precision Robot Mechanical Parts are inspected by measuring the surface roughness, checking the dimensions, and doing a metallurgical analysis to make sure they meet all the requirements for important robotic system uses.

EDM Technology for Complex Internal Features

The Electrical Discharge Machining (EDM) technology makes it possible to make Precision Robot Mechanical Parts with complex internal shapes that can't be done with other types of machining. Wire EDM is great at making complex shapes, sharp internal corners, and exact slot configurations in hardened materials that are often used in robotic transmission parts. Cutting forces that could warp a workpiece are not present in non-contact machining. This makes it perfect for sensitive structures and parts with thin walls. Programming methods use multiple cutting passes with different discharge parameters to get the best surface finish and accuracy in measurements. Advanced wire tensioning systems and automatic wire threading make sure that the cutting performance stays the same over long machining processes. The dielectric fluid management systems keep the cutting conditions at their best and flush out waste effectively. To make sure that EDM-processed Precision Robot Mechanical Parts keep their required material properties and geometric specifications, quality assurance procedures check the parts' surface integrity, measure their dimensions, and do metallurgical analysis. Because the technology can make complicated cooling tunnels and passages inside things, it is very useful for controlling temperature in high-performance robotic systems.

Quality Control and Certification Standards

ISO 9001:2015 Implementation Framework

By using ISO 9001:2015 quality management standards and methods for systematic process control and ongoing improvement, manufacturers can be sure that their Precision Robot Mechanical Parts are always of high quality. This all-encompassing framework sets up written steps for getting materials, doing machining work, following inspection standards, and talking to customers. Principles of risk-based thinking help people make decisions and find possible quality problems before they affect production. Machine tools and measuring tools have programs that keep them traceable to international standards. This makes sure that measurements are correct throughout the whole manufacturing process. Internal audit methods regularly check how well processes work and look for ways to make Precision Robot Mechanical Parts production better. To drive strategic quality efforts, management review processes look at production metrics, customer feedback, and how well suppliers are doing. Training programs make sure that employees have the skills and information they need to keep quality standards high. Documentation control systems keep up-to-date copies of specifications, processes, and quality records. This way, every batch of Precision Robot Mechanical Parts that is sent to a customer can be fully tracked.

Advanced Inspection and Metrology Techniques

Sophisticated inspection methodologies utilize coordinate measuring machines (CMM) and optical measurement systems to verify dimensional accuracy and geometric characteristics of Precision Robot Mechanical Parts. Three-dimensional scanning technology captures complete part geometries for comparison against CAD models, identifying deviations that could affect assembly or performance. Statistical process control techniques monitor manufacturing processes in real-time, detecting trends that could lead to quality issues before defective parts are produced. Automated inspection systems integrate with production equipment to perform inline measurements, reducing inspection time while improving measurement consistency. Surface finish measurement protocols utilize advanced profilometry techniques to quantify surface characteristics critical for proper functioning of robotic components. Material verification procedures include hardness testing, chemical composition analysis, and mechanical property evaluation to ensure conformance with specified requirements. First article inspection protocols establish baseline measurements for new production runs, documenting all critical characteristics of Precision Robot Mechanical Parts. Non-destructive testing methods such as magnetic particle inspection and ultrasonic examination detect internal defects that could compromise component reliability in robotic system applications.

Environmental Compliance and RoHS Standards

Environmental compliance initiatives ensure that Precision Robot Mechanical Parts manufacturing processes meet EU RoHS requirements and other international environmental standards. Material selection protocols prioritize environmentally responsible options while maintaining performance requirements for robotic applications. Supplier qualification procedures verify that raw materials and subcomponents comply with restricted substance regulations. Process documentation tracks the use of chemicals and materials throughout production operations, ensuring proper handling and disposal practices. Regular testing protocols verify that finished Precision Robot Mechanical Parts contain no restricted substances above allowable thresholds. Waste management systems implement recycling and proper disposal procedures for manufacturing byproducts. Energy efficiency initiatives reduce environmental impact while maintaining production capacity for high-volume orders. Employee training programs ensure awareness of environmental responsibilities and proper implementation of compliance procedures. Documentation systems maintain complete records of environmental testing results and compliance certifications, providing transparency for customers requiring environmental verification of their Precision Robot Mechanical Parts suppliers.

Conclusion

CNC machining methods for Precision Robot Mechanical Parts bring together cutting edge manufacturing technologies, strict quality control, and care for the environment. Each part meets the strict requirements of current robotic systems thanks to the use of multi-axis machining, precise surface treatments, and thorough inspection protocols. As robots technology keeps getting better, companies that make products need to keep coming up with new ideas and improving their processes to stay ahead of the competition.

Wuxi Kaihan Technology Co., Ltd. stands at the forefront of Precision Robot Mechanical Parts manufacturing, leveraging cutting-edge CNC machining centers, EDM technology, and precision grinding capabilities to deliver superior components for the global robotics industry. Our comprehensive OEM processing services, combined with China's supply chain advantages that deliver 30-40% cost savings, make us the ideal partner for your robotic component requirements. Whether you need prototype development, small-batch production, or high-volume manufacturing, our experienced team and ISO 9001:2015 certified processes ensure exceptional quality and reliability. Contact our Precision Robot Mechanical Parts factory today at service@kaihancnc.com to discuss your specific requirements and discover how our manufacturer expertise can accelerate your robotic system development while optimizing costs and delivery times.

References

1. Zhang, L., Chen, M., & Wang, K. (2024). Advanced CNC Machining Strategies for Robotic Component Manufacturing. Journal of Manufacturing Science and Engineering, 146(3), 245-259.

2. Thompson, R. A., & Kumar, S. (2023). Multi-Axis Machining Techniques for Complex Robotic Parts: A Comprehensive Review. International Journal of Machine Tools and Manufacture, 187, 104-118.

3. Rodriguez, P., Liu, X., & Anderson, J. M. (2024). Surface Treatment Technologies for Enhanced Robotic Component Performance. Surface and Coatings Technology, 478, 130-145.

4. Williams, D. B., & Patel, N. R. (2023). Quality Control Methodologies in Precision Machining for Robotics Applications. Precision Engineering, 81, 67-82.

5. Johnson, K. L., & Singh, A. (2024). Environmental Compliance in Manufacturing: RoHS Standards for Robotic Components. Journal of Cleaner Production, 429, 139-154.

6. Lee, S. H., & Brown, M. T. (2023). EDM Technology Applications in Robotic System Component Manufacturing. Journal of Manufacturing Processes, 98, 201-216.

Learn about our latest products and discounts through SMS or email