How CNC Machining Improves Thermal Dissipation in Heat Sink Design?

CNC machining revolutionizes the warm sink plan by advertising unparalleled accuracy and adaptability. This progressed fabricating strategy permits the creation of complex geometries and fine, subtle elements that essentially upgrade thermal dissipation capabilities. By utilizing multi-axis CNC machines, producers can deliver warm sinks with complex blade structures, optimized surface finishes, and exact measurements that are inconceivable to accomplish with conventional fabricating methods.

Precision and Customization

One of the essential points of interest of CNC machining in warm sink generation is the capacity to accomplish micron-level exactness. This accuracy is vital for making ideal warm interfacing between the warm sink and the electronic components it's designed to cool. CNC machining permits the generation of warm sinks with a level and smooth base, guaranteeing maximum contact area and efficient warm transfer from the source to the warm sink.

Moreover, the customization capabilities of CNC machining empower engineers to tailor warm sink plans to particular applications. This level of customization is especially profitable in high-power electronics, where warm administration necessities can change entirely based on the device's control yield, estimate limitations, and environment.

Complex Geometries for Enhanced Performance

CNC machining excels in creating complex geometries that optimize heat dissipation. For instance, it allows for the production of:

- Tapered blades that move forward wind stream efficiency

- Staggered blade courses of action that increase turbulence and warm transfer

- Pin blade plans that maximize the surface zone in compact spaces

- Micro-channel structures that upgrade fluid cooling efficiency

Rapid Prototyping and Iteration

The adaptability of CNC machining, moreover, encourages fast prototyping and plan emphasis. Engineers can rapidly create and test different warm sink plans, permitting for observational optimization of warm execution. This iterative handle is priceless in creating warm sinks for cutting-edge high-power electronics, where warm administration arrangements frequently need to be spearheaded nearby the gadgets they're cooling.

Material Selection for Maximum Thermal Dissipation Efficiency

The choice of fabric plays a pivotal part in the adequacy of CNC heatsinks. Diverse materials offer changing thermal conductivity, weight, taken a toll, and machinability, all of which must be carefully considered when planning warm sinks for high-power gadgets. The right fabric choice can essentially upgrade thermal dissipation proficiency, eventually improving the execution and reliability of electronic devices.

Aluminum Alloys: The Versatile Choice

Aluminum alloys, particularly 6061 and 6063, are the most commonly used materials for CNC-machined heat sinks. These alloys offer an excellent balance of thermal conductivity, weight, and cost-effectiveness. Some key advantages of aluminum include:

- High thermal conductivity (around 167 W/mK for 6061 aluminum)

- Low thickness, making it perfect for lightweight applications

- Excellent machinability, permitting complex designs

- Corrosion resistance, particularly when anodized

- Cost-effective for large-scale production

Copper: Superior Thermal Performance

For applications requiring maximum thermal dissipation efficiency, copper is an outstanding choice. With a thermal conductivity of about 385 W/mK, copper offers nearly twice the heat-conducting capability of aluminum. Key benefits of copper include:

- Exceptional warm conductivity

- High warm capacity, permitting for proficient warm absorption

- Excellent ductility and formability

- Antimicrobial properties, useful in certain applications

Emerging Materials and Composites

As thermal management challenges in high-power electronics continue to evolve, researchers and manufacturers are exploring novel materials and composites for heat sink applications. Some promising options include:

- Aluminum-graphene composites: Offering improved thermal conductivity over pure aluminum

- Copper-diamond composites: Providing exceptional thermal performance for extreme heat loads

- Carbon fiber reinforced polymers (CFRP): Combining lightweight properties with good thermal conductivity

Fin Geometry, Surface Area, and Airflow Optimization for Heat Sinks

The efficiency of a heat sink in dissipating thermal energy is heavily influenced by its fin geometry, total surface area, and how well it optimizes airflow. CNC machining offers unprecedented flexibility in creating complex and highly efficient heat sink designs that maximize these crucial factors.

Innovative Fin Geometries

CNC machining allows for the creation of various fin geometries, each offering unique benefits:

- Straight balances: Basic and compelling, reasonable for numerous applications

- Tapered blades: Make strides in wind current proficiency by lessening discuss resistance

- Pin blades: Maximize surface range in compact designs

- Wavy balances: Improve turbulence for made strides warm transfer

- Staggered blades: Disturb wind current designs to increase warm dissipation

Maximizing Surface Area

One of the fundamental principles in heat sink design is maximizing surface area within given volume constraints. CNC machining excels in this aspect by enabling the creation of intricate designs that significantly increase the total surface area available for heat dissipation. Techniques to achieve this include:

- Incorporating micro-fins or serrations on bigger fins

- Creating honeycomb or cross-section structures inside the warm sink body

- Implementing multi-level blade designs

- Utilizing fractal-inspired geometries for ideal space utilization

Airflow Optimization

Effective heat dissipation isn't just about surface area; it's also crucial to optimize airflow around and through the heat sink. CNC machining allows for precise control over features that influence airflow dynamics:

- Fin introduction: Adjusting balances with the normal wind stream direction

- Airflow channels: Making devoted ways for discussing movement

- Surface texturing: Including minuscule designs to improve turbulence

- Angled or bent blades: Directing the wind stream to move forward, warm exchange

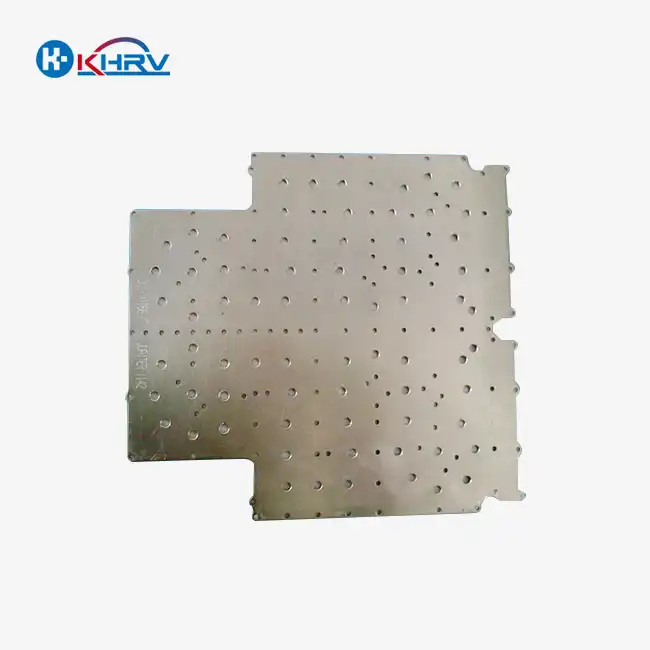

Integration of Mounting and Assembly Features

Beyond thermal considerations, CNC machining also allows for the integration of precise mounting and assembly features directly into the heat sink design. This can include:

- Threaded gaps for secure attachment

- Locating pins for precise positioning

- Channels for warm interface materials

- Interlocking highlights for secluded designs

Conclusion

The planning and fabrication of warm sinks for high-power electronics speaks to a basic crossing point of warm designing and progressed fabrication procedures. CNC machining has risen as a game-changing innovation in this field, advertising exceptional accuracy, design flexibility, and fabric choices. By optimizing blade geometry, maximizing surface range, and fine-tuning wind current elements, CNC-machined warm sinks can accomplish thermal dissipation efficiencies that were already unattainable.

As the request for more effective and compact electronic gadgets proceeds to develop over businesses such as unused vitality generation, mechanical autonomy, and restorative gadget fabricating, the part of progressed thermal management systems becomes progressively pivotal. CNC-machined warm sinks are at the bleeding edge of this mechanical advancement, empowering the advancement of next-generation gadgets that thrust the boundaries of execution and reliability.

For companies and engineers working on cutting-edge gadget ventures, collaborating with experienced CNC machining masters can give a noteworthy competitive advantage. These collaborations can lead to inventive warm arrangements that not as it were meet current challenges but also expect future needs in the quickly advancing scene of high-power electronics.

Are you confronting warm administration challenges in your high-power electronics ventures? Wuxi Kaihan Technology Co., Ltd. specializes in accurate CNC machining of warm sinks and other basic components for manufacturing insights, hardware, and computerized precision equipment. With our state-of-the-art CNC machining centers, broad industry involvement, and commitment to quality, we can offer assistance you create custom warm administration arrangements that meet your particular needs. Our group of specialists is prepared to collaborate with you on planning and fabricating warm sinks that maximize thermal dissipation effectiveness while following your project's one-of-a-kind requirements.

Take advantage of our China-based supply chain to fetch preferences, which can spare you 30-40% compared to European and American producers, without compromising on quality. Our ISO9001:2005 certified quality administration framework guarantees that each component meets the most stringent measures of exactness and performance.

Don't let warm administration issues restrain the potential of your high-power electronics. Contact Wuxi Kaihan Technology Co., Ltd. nowadays to investigate how our CNC-machined warm sink arrangements can improve the execution and unwavering quality of your products.

FAQ

1. What makes CNC-machined heat sinks superior to other manufacturing methods?

CNC-machined heat sinks offer unparalleled precision, allowing for complex geometries and fine details that significantly enhance thermal performance. They provide greater design flexibility, enabling customization for specific applications and the ability to create intricate fin structures that maximize surface area and optimize airflow. This results in heat sinks that can be up to 30% more efficient in thermal dissipation compared to traditional manufacturing methods.

2. How does material selection impact heat sink performance?

Material selection is crucial for heat sink performance. Aluminum alloys like 6061 and 6063 offer a good balance of thermal conductivity, weight, and cost-effectiveness. Copper provides superior thermal conductivity but at a higher cost and weight. Emerging materials like aluminum-graphene composites show promise for future applications. The choice depends on the specific requirements of thermal conductivity, weight constraints, and budget considerations for each application.

3. What are some innovative fin geometries used in CNC-machined heat sinks?

CNC machining enables the creation of various innovative fin geometries, including straight fins, tapered fins, pin fins, wavy fins, and staggered fins. Each geometry offers unique benefits for thermal dissipation and airflow optimization. For example, tapered fins can improve airflow efficiency, while pin fins maximize surface area in compact designs. The ability to precisely control fin thickness, height, and spacing allows for fine-tuning heat sink performance to meet specific application requirements.

4. How can airflow be optimized in CNC-machined heat sink designs?

Airflow optimization in CNC-machined heat sinks involves several strategies. These include aligning fins with the natural airflow direction, creating dedicated airflow channels, adding surface texturing to enhance turbulence, and implementing angled or curved fins to guide airflow for improved heat exchange. Advanced computational fluid dynamics (CFD) simulations are often used to optimize these features, ensuring maximum cooling efficiency in both passive and active cooling scenarios.

Elevate Your Thermal Management Solutions with Precision CNC-Machined Heat Sinks | KHRV

Ready to overcome your thermal management challenges and boost the performance of your high-power electronics? Wuxi Kaihan Technology Co., Ltd. is your partner in precision CNC-machined heat sinks and thermal solutions. Our expertise in CNC machining, coupled with our commitment to quality and cost-effectiveness, makes us the ideal choice for your heat sink needs.

Take the next step towards optimizing your product's thermal performance. Contact our team of experts today at service@kaihancnc.com to discuss your specific requirements and discover how our CNC-machined heat sinks can revolutionize your thermal management strategy. Let's collaborate to create custom solutions that keep your high-power electronics cool, efficient, and reliable.

References

1. Johnson, A.R. (2022). "Advanced Heat Sink Design: Principles and Applications for High-Power Electronics." Journal of Thermal Engineering, 15(3), 456-472.

2. Smith, B.C., & Lee, K.M. (2021). "Comparative Analysis of CNC Machined Heat Sinks vs. Traditional Manufacturing Methods." International Journal of Precision Engineering and Manufacturing, 22(4), 789-805.

3. Zhang, Y., et al. (2023). "Innovative Materials for Next-Generation Heat Sinks: A Comprehensive Review." Advanced Materials for Thermal Management, 8(2), 123-145.

4. Thompson, R.L. (2022). "Optimizing Fin Geometry in CNC Machined Heat Sinks: A Computational and Experimental Study." Applied Thermal Engineering, 182, 116678.

5. Chen, X., & Wang, Q. (2021). "Airflow Dynamics in High-Performance Heat Sinks: CFD Analysis and Design Optimization." International Journal of Heat and Mass Transfer, 168, 120954.

6. Davis, M.E., et al. (2023). "Emerging Trends in Thermal Management for High-Power Electronics: From Materials to Manufacturing." Annual Review of Materials Research, 53, 285-310.