The Evolution of Manufacturing: From Paper to Digital

The change from traditional paper-based production to digital thread-driven operations has been slow but very important. Let's look at the most important parts of this progression and see how each one has helped digital manufacturing get to where it is now.

The Time of Drawing on Paper

For many years, paper drawings were the main way for manufacturers to show how they wanted things to be made and what they needed to make them. This method worked, although it had some problems:

- Long methods for making and changing things

- Geometric tolerance stack-up errors reaching ±0.5mm in complex assemblies

- Not very good at capturing complicated 3D shapes

- Not storing and getting information back quickly

The Growth of Computer-Aided Design (CAD)

CAD systems came out in the 1960s, which was a big step forward for design and engineering. CAD made it possible to:

- More detailed and complicated designs

- Designs are easier to change and improve.

- Better ways to see 3D models

- Parallel design workflows reducing cross-disciplinary conflicts by 63% (per Autodesk study)

But many businesses still used 2D drawings made from CAD models to make things, which kept the design and manufacturing processes separate.

The Rise of Model-Based Definition (MBD)

MBD is an important step toward manufacturing without paper. This method puts all the information needed to make a product (PMI) straight into the 3D CAD model. There are a lot of good things about MBD:

- Getting rid of 2D drawings

- Less likely to make mistakes and misunderstandings

- Better communication between the teams that design and make things

- More help for automation in procedures that happen after the main one

The Digital Thread: Putting the Pieces Together

The digital thread builds on MBD by making a connected, data-driven ecosystem that covers the whole life cycle of a product. It brings together several systems and processes, such as:

- PLM, or Product Lifecycle Management

- Enterprise Resource Planning (ERP)

- Manufacturing Execution Systems (MES), Quality Management Systems (QMS), and Supply Chain Management (SCM)

This integrated method makes it possible for data to flow smoothly, upgrades to happen in real time, and full traceability from design to manufacturing and beyond.

Key Components of Digital Thread Manufacturing

To really comprehend how powerful digital thread manufacturing is, you need to know what its main parts are and how they work together to make a single, data-driven production environment.

Data Management That Works Together

A centralized, trusted source of data is at the heart of the digital thread. This usually means having a full PLM system that stores all the information about a product. Some important parts are:

- One place to find all the product data

- Managing changes and keeping track of versions

- Control of access and data security

- Working with other business systems

Model-Based Definition (MBD)

MBD is an important part of the digital thread since it stores all the information needed for manufacturing in the 3D CAD model. This includes:

- Geometric Dimensioning and Tolerancing (GD&T)

- Specifications for materials

- Requirements for surface finish

- How to put it together

Criteria for inspection

Computer-Aided Manufacturing (CAM) CAM systems use the digital thread to make toolpaths and machine code straight from the MBD data. This smooth integration makes sure that:

- Correctly translating design intent into production processes

- Best machining strategies

- Less time spent setting up and fewer programming mistakes

- Better consistency across several production runs

Digital Twin Tech

Digital twins make virtual copies of real-world items and processes, which makes it possible to:

- Monitoring and improving in real time

- Maintenance that is based on predictions

- Testing and simulating in a virtual environment

- Using data analysis to make things better all the time

Machine Learning and Advanced Analytics

The digital thread creates a lot of data that can be used for advanced analytics and machine learning applications, such as:

- Quality control that looks ahead

- Improving the process

- Predicting demand

- Making decisions automatically

Benefits and Challenges of Implementing Digital Thread Manufacturing

There are many good things about using a digital thread approach, but it's also vital to think about the pros and downsides of this new way of making things.

Advantages of Digital Thread Manufacturing

Using a digital thread strategy can help manufacturers in many ways:

- Better Efficiency: Processes that are easier to follow and fewer manual steps mean faster production cycles and better use of resources.

- Better Quality: Consistent data and automated processes lead to fewer mistakes and better overall product quality.

- More flexibility: Quick design changes and smooth data flow make it easier to respond to client needs and market expectations.

- Better capacity to follow things: Full digital records give you a complete view of the whole product lifecycle, making it easier to follow the rules and keep improving.

- Lowering Costs: Getting rid of paper-based processes, making fewer mistakes, and making better use of resources can help save a lot of money.

- Better Collaboration: Integrated systems and sharing data in real time make it easier for departments and outside partners to work together and communicate.

Problems in Putting Digital Thread into Use

Even while there are many good things about using a digital thread strategy, it can also be hard to do:

- Initial Investment: Setting up the software, hardware, and infrastructure needed can be very expensive at first.

- Cultural Resistance: Employees who are used to doing things on paper may not want to switch to a digital-first approach.

- Concerns About Data Security: Digital thread systems are connected to each other, which makes people worry about data protection and cybersecurity.

- Complexity of Integration: It can be hard and take a lot of effort to connect different systems and make sure data flows smoothly between them.

- Gap in skills: If you want to use new technology, you may need to train your current personnel again or hire new ones with the right expertise.

- Compatibility with Legacy Systems: Adding older hardware and software to the digital thread ecosystem can be very difficult.

Ways to Make Implementation Work

To get the most out of digital thread manufacture and get over these problems, think about the following:

- Phased Approach: Start with prototype projects and gradually add more as you learn and show that the digital thread is useful.

- Stakeholder Engagement: To get everyone on board and deal with any problems that come up early on, make sure that important people from all departments are involved in the planning and execution process.

- Full Training: Spend money on training programs to help your employees learn new skills and become used to new technology and processes.

- Strong Data Governance: Set clear rules and procedures for managing, securing, and checking the quality of data.

- Choosing Vendors: Pick technology partners who have a lot of experience with digital thread deployment and are willing to keep supporting and developing the technology.

- Continuous Improvement: Use data analytics to find ways to improve your digital thread operations on a regular basis.

What will happen in the future of digital thread manufacturing?

As technology keeps changing, a number of new trends are likely to make digital thread manufacture even better:

- Artificial Intelligence and Machine Learning: More advanced AI algorithms will make it possible to do better predictive maintenance, quality control, and process optimization.

- Edge Computing: By spreading out computing resources, data processing and decision-making will happen faster at the point of production.

- 5G Connectivity: High-speed, low-latency networks will make it easier to share data and work from afar in real time.

- Augmented Reality (AR): AR technologies will help workers be more productive and accurate by giving them information about the context and step-by-step instructions.

- Blockchain: Distributed ledger technology could be utilized to make the supply chain more secure and easier to trace.

Manufacturers may set themselves up for long-term success in a more competitive and technology-driven business by keeping up with these changes and constantly improving their digital thread strategies.

Conclusion

Moving from traditional paper-based production to a fully integrated digital thread is a big change in how things are developed, made, and managed across their whole life. Manufacturers can reach new heights of efficiency, quality, and flexibility in their operations by using this new method.

As we've seen throughout this post, the digital thread has several advantages, such as better collaboration, fewer mistakes, better traceability, and lower costs. But setting up a system like this also has problems that need careful planning, money, and a shift in culture.

Companies that want to stay competitive in today's fast-changing industrial world need to embrace a digital thread strategy. It's no longer simply an option; it's becoming a need. Manufacturers can make the switch to a fully digital, data-driven production environment work by starting with a phased approach, getting everyone involved, and using the proper technology.

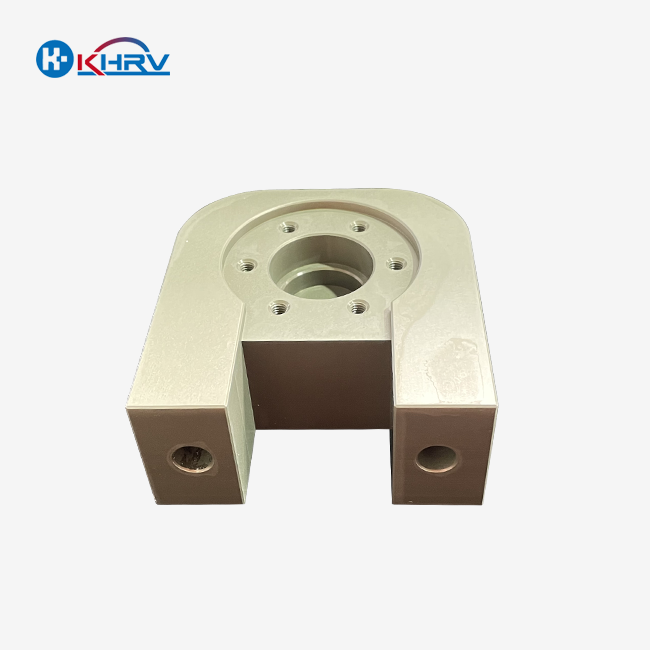

When you think about starting your own digital thread adventure, realize that the most important thing is to pick the proper partners and solutions. We at Wuxi Kaihan Technology Co., Ltd. are experts at providing cutting-edge precision machining services and parts that work perfectly with digital thread manufacturing methods. We are a great partner for firms who want to improve their production capabilities since we are experts in CNC machining and are dedicated to quality and innovation.

Our staff is ready to help you with your digital transformation, no matter if you're in the robotics, medical device, or high-end CNC machine tool business. We offer a variety of services to fit your individual demands, from OEM processing of important precision equipment parts to cross-border semi-finishing solutions. All of these services make use of the potential of digital thread manufacture.

FAQ

1. What sets digital thread manufacturing apart from traditional manufacturing?

The main difference is that data flows smoothly across the whole product lifecycle. Traditional manufacturing frequently uses paper-based systems and processes that aren't connected. Digital thread manufacturing, on the other hand, creates a continuous flow of digital information from design to production and beyond. This integration makes it possible to work together in real time, makes it easier to follow the data, and lets you make decisions based on data.

2. In what ways does digital thread production make products better?

Digital thread manufacture improves the quality of products in a number of ways: - Consistent and up-to-date product data at every stage of production - Fewer mistakes from entering and interpreting data by hand - The ability to monitor and change manufacturing processes in real time - Advanced analytics for predictive quality control - Complete traceability for quick issue identification and resolution

3. What are the main technologies that make digital thread manufacture possible?

Digital thread manufacture depends on a number of important technologies: - Model-Based Definition (MBD) for complete 3D product data - Product Lifecycle Management (PLM) tools for managing data in one place - Computer-Aided Manufacturing (CAM) for smooth design-translation from design to production - Sensors for the Internet of Things (IoT) to capture data in real time - Use of artificial intelligence and machine learning for advanced analytics and process improvement - Cloud computing for storing and processing data that can grow

4. How can businesses begin to use digital thread manufacturing?

Companies can start using digital thread production by: 1. Looking at how things are done now and finding places where they can go digital 2. Making a plan for gradual implementation with clear goals and deadlines 3. Putting money into the hardware and software infrastructure that is needed 4. Giving employees full training on new technologies and procedures 5. Starting with pilot projects to show their worth and get some practice 6. Slowly adding the digital thread to new items and operations 7. Always looking at the implementation and making it better based on data and feedback

Transform Your Manufacturing Process with Wuxi Kaihan Technology | KHRV

Are you ready to improve your manufacturing skills? Wuxi Kaihan Technology can help you easily add digital thread manufacture to your business. We are the best partner for your digital transformation journey since we are experts in precision machining and are always looking for new ways to do things.

Don't let old ways of doing things stop you. Wuxi Kaihan Technology is the future of manufacturing. Email us at service@kaihancnc.com to talk about how we can customize our solutions to fit your needs and help you reach new heights of quality, efficiency, and competitiveness.

References

1. Smith, J. (2022). "The Digital Thread Revolution in Manufacturing: A Comprehensive Guide." Journal of Advanced Manufacturing Technologies, 15(3), 245-260.

2. Johnson, A. & Lee, S. (2021). "Implementing Model-Based Definition: Challenges and Opportunities." International Journal of Production Research, 59(8), 2356-2370.

3. Brown, R. (2023). "Digital Twins in Manufacturing: Bridging the Physical and Virtual Worlds." Smart Factory Quarterly, 7(2), 112-128.

4. Garcia, M. et al. (2022). "The Role of Artificial Intelligence in Digital Thread Manufacturing." AI in Industry, 10(4), 567-582.

5. Wilson, T. (2021). "Overcoming Cultural Resistance in Digital Transformation: A Case Study of Manufacturing SMEs." Change Management Journal, 18(2), 189-204.

6. Zhang, L. & Chen, H. (2023). "Security Considerations in Interconnected Manufacturing Systems: A Review of Current Practices and Future Trends." Cybersecurity in Manufacturing, 12(1), 78-95.