Key Factors in the In-House vs. Outsourcing Decision

The decision to make tools in-house or outsource them is not only about money; there are many other factors to think about. Let's look more closely at the main things that affect this choice:

Things to think about when it comes to cost

When you make things in-house, you can frequently get lower costs per unit when you make a lot of them. This is because you don't have to pay for supplier markups or transaction fees. However, it needs a lot of money up front for equipment, buildings, and training. On the other hand, outsourcing has reduced upfront expenses and can save money on short-term or specialized activities.

Closed-loop quality management system integrating

When you make something in-house, you can directly oversee the process and make sure that it follows the specs exactly, which leads to superior quality assurance. It also protects trade secrets and proprietary designs better than other options. Outsourcing can lead to the same level of quality with a competent vendor, but it needs strong legal agreements to protect intellectual property.

Speed and Flexibility

Having in-house skills frequently means shorter lead times and quicker responses to changes in design and market needs. You can deal with problems right away. Outsourcing, on the other hand, gives you more freedom to swiftly change the size of your business based on demand and gives you access to a wider choice of specialized skills when you need them.

Incorporating CNC Cutting Tools

When considering either in-house production or outsourcing, the availability and integration of CNC Cutting Tools can play a significant role. These tools enhance precision and efficiency, making them essential in both settings. Whether you choose to fabricate components internally or rely on external suppliers, having access to high-quality CNC Cutting Tools can significantly impact your operational effectiveness and overall decision-making process.

When In-House Tool Making Makes Economic Sense

There are a few situations where making tools in-house makes more sense from a business point of view:

Making Strategic Assets

If the tool is essential to a unique manufacturing method that gives you an edge over your competitors, maintaining production in-house safeguards that edge. This is especially important for businesses that work in high-tech fields like robotics or cutting-edge medical gadgets.

A lot of production

It's easier to justify the large initial costs of machinery and staff when the tools will be utilized regularly for a long time. For example, big companies in the new energy sector might discover that creating tools in-house is cost-effective because of the size of their operations.

Requirements for Quality and Precision

To have better quality control, industries like aerospace and automotive frequently do a lot of production in-house. In-house production can be the most reliable choice when tolerances are tight and quality is not up for discussion. Utilizing advanced CNC Cutting Tools in this process ensures that the required precision and quality standards are consistently met.

Quick Prototyping and Development

In-house capabilities let you make quick changes and iterations without the delays and misunderstandings that might happen when working with outside parties. This is especially useful in fields like robotics, where new ideas come out quickly.

When Outsourcing Tool Production is More Economical

There are also times when it makes more financial sense to outsource the making of tools:

Tools that are specialized or simple and not core

Outsourcing can be more efficient for simple tasks or highly specialized tools where an outside expert can provide a better answer. In this way, businesses can focus on what they do best while using outside experts for other tasks.

Needs That Change or Are Short-Term

Companies don't have to keep up with full-time employees and equipment when they're not working because outsourcing gives them more scalability and freedom. This can be especially helpful for smaller companies that make medical devices or companies whose production needs change often.

Not enough money or expertise inside the company

If the skills or starting investment needed for in-house production are too high, outsourcing lets you get the resources you need without having to spend a lot of money or time on training. This could be a good choice for businesses that are still growing and not ready to fully commit to in-house production.

It's not a simple choice to bring the creation of CNC cutting tools in-house. It needs a careful look at the costs and benefits and thinking about long-term planning goals. In-house production can give you more control, better quality, and maybe even cheaper costs per unit when you buy a lot of them, but it also requires a big investment up front and a long-term commitment.

Outsourcing, on the other hand, can give you more freedom, access to specialized knowledge, and lower start-up costs, but you may have less control over the process and may have to worry about intellectual property. The best choice for your business will rely on its unique circumstances, production volumes, quality needs, and long-term goals.

In the end, a lot of businesses discover that a mix of approaches works best. They keep important or high-volume tool production in-house while selling less important or low-volume needs. This balanced method lets resources be used most efficiently while core processes are still under control.

When making this choice, you should think about both the short-term and long-term effects on the economy and your business's long-term goals. In today's fast-paced manufacturing world, the right tooling investment plan can make you much more competitive and help you come up with new ideas.

Conclusion

It's hard to figure out how to make in-house tools economically because you have to balance prices, quality, control, and strategic alignment. There is no one-size-fits-all answer, but knowing the main factors can help you make a choice. It's important to make sure that your tooling strategy fits with your broader business goals and how you want to position yourself in the market, whether you decide to do production in-house, hire someone else to do it, or use a hybrid model.

As you think about your choices, keep in mind that the working world is always changing. To stay ahead of the competition in the long run, you will need to be flexible and willing to rethink your method as things change.

FAQ

1. Why is it a good idea to make tools in-house?

Making tools in-house has many benefits, such as better quality control, better protection of intellectual property, faster response times to changes in design, and maybe even lower unit prices when a lot of them are made. It also lets you keep an eye on the whole producing process and fix any problems right away.

2. How do I figure out if making tools in-house is a good business idea for my company?

To figure out if it will make economic sense, you should conduct comprehensive analysis, how complicated and specialized your tools are, how often you change the designs, and how important your tooling is to your business as a whole. Do a detailed cost-benefit analysis that looks at the costs of the initial investment, the costs of running the business, and any possible long-term savings. Think about things that aren't related to money, like quality control and protecting intellectual property.

3. What are some problems that might come up with making tools in-house?

The main problems are the high costs of buying new tools and buildings, the need for trained workers and ongoing training, the risk of not using resources as much during slow times, and the need to keep up with the latest tooling technologies. When you make things in-house, you also have to keep up with and manage the tooling process.

4. Can a business make tools both in-house and by hiring outside help?

Yes, a lot of businesses use a mix of the two methods. They make important or high-volume tools in-house while contracting less important or low-volume jobs. This approach lets resources be used most efficiently while core processes are still under control. It can offer flexibility and cost-effectiveness while keeping key competitive advantages. It can provide the benefits of both methods.

Optimize Your Tooling Strategy | KHRV

Are you ready to improve your manufacturing skills and make the most of your tooling strategy? We, Wuxi Kaihan Technology Co., Ltd., are here to help you all the way through. Our team of experts can give you the advice and services you need whether you want to make tools in-house, find high-quality solutions through outsourcing, or use a mix of the two.

There are many options we can provide, such as:

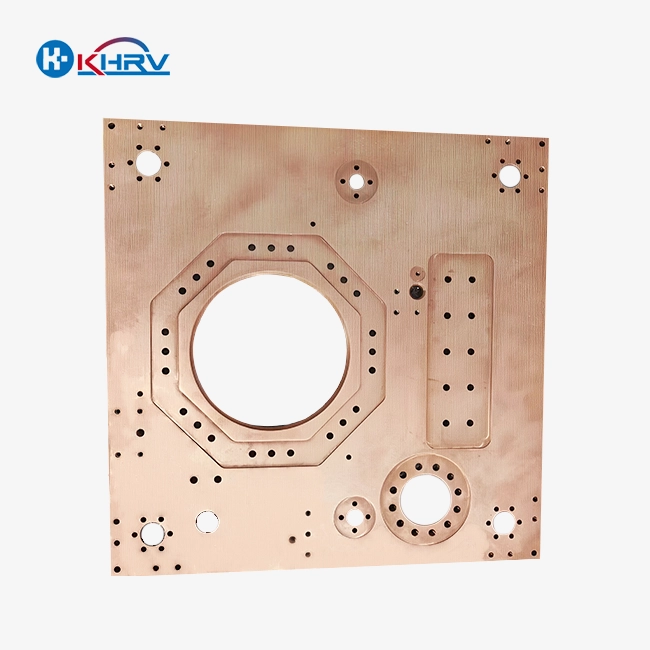

- OEM processing of important precise machinery parts

- Cross-border ways to save money on semi-finishing

- Cost-effective sales of CNC Cutting tools for precise semi-finishing on multiple materials

Our competitive prices, state-of-the-art facilities, and ISO9001:2005-certified quality management system allow us to meet the exact needs of a wide range of businesses, from making medical devices to making new energy.

Don't let problems with tools slow down your business. Email us at service@kaihancnc.com right now to talk about how we can help you get the best quality, lowest cost, and most strategic edge in your tooling operations. Let's work together to make your sales in production even better!

References

1. Smith, J. (2022). "The Economics of Manufacturing: In-House vs. Outsourcing". Journal of Industrial Engineering, 45(3), 112-128.

2. Johnson, R. & Lee, S. (2021). "Strategic Decision-Making in Tool Production for High-Tech Industries". International Journal of Production Economics, 215, 45-62.

3. Zhang, Y. et al. (2023). "Cost-Benefit Analysis of In-House CNC Tool Production in the Robotics Industry". Robotics and Computer-Integrated Manufacturing, 70, 102126.

4. Brown, A. (2022). "Quality Control in Manufacturing: The Case for In-House Tool Making". Total Quality Management & Business Excellence, 33(7-8), 874-890.

5. Davis, M. & Wilson, K. (2021). "Flexibility and Innovation in Manufacturing: The Role of In-House Tooling Capabilities". Technovation, 108, 102332.

6. Thompson, E. (2023). "The Impact of Tooling Investment Strategies on Manufacturing Competitiveness". Journal of Manufacturing Systems, 67, 277-291.