Key Design Factors Influencing Tool Stability

Several design elements of CNC cutting tool holders directly impact tool stability and, consequently, machining performance. Let's explore these factors in detail:

Material Selection and Rigidity

The material that the tool case is made of is very important to how well it works. Tool cases of good quality are usually made from heat-treated alloy steel or carbide, which are stronger and more rigid materials. These materials help reduce tremors and keep their shape under strong cutting forces, which makes the tool more stable.When high-speed cutting is being done, rigidity is especially important for keeping the tool stable. A stiff tool holder keeps the tool from bending or vibrating too much, which makes cuts more accurate and improves surface finishes. Some more modern tool holder designs use composite materials or special alloys to make them even more rigid while also making them lighter. This strikes the best balance between stability and machine responsiveness.

Advanced Interface Engineering

It's very important that the part where the tool holder meets the machine frame is stable. When you connect two devices, the link is always safe and stable thanks to interfaces like HSK (Hollow Shank Taper) or BT (Big-Plus Taper). There is less runout and more contact area with these designs, which makes the cutting processes more stable and less likely to be affected by shaking.How the cutting tool and its case attach to each other is also important. The cutting tool fits perfectly and is lined thanks to precision-ground surfaces and tight tolerances in this area. This makes the whole thing more stable and accurate.

Balance and Symmetry

To keep cutting conditions stable, CNC Cutting Tool Holder especially at high spindle speeds, tool holders must be designed with the right amount of balance and uniformity. When tool mounts are well-balanced, they lower centrifugal forces and stop harmful harmonics from building up, which can cause chattering and poor surface finishes.Precision grinding and dynamic balancing are two advanced manufacturing methods that are used to make tool holders that are almost perfectly symmetrical. Some designs go so far as to include eccentric relief grooves or asymmetrical shapes to even out the uneven forces caused by the cutting tool or coolant channels.

Advanced Design Features for Enhanced Stability

Modern CNC cutting tool holders incorporate various advanced design features aimed at further improving tool stability and overall machining performance:

Hydraulic and Heat-Shrink Clamping Systems

Hydraulic expansion and heat-shrink systems are two new types of clamping mechanisms that are better at holding tools than standard mechanical clamping methods. These methods make sure that the clamping force is the same all the way around the tool shank. This makes the concentricity better, the runout less, and the stability better.Hydraulic clamping systems use fluid pressure to make a sleeve grow around the tool shank. This makes a secure grip that stays strong even when cutting heavy things. Heat-shrink methods, on the other hand, use the growth and shrinkage of heat to make an interference fit between the tool and the holder. This makes the connection very rigid and accurate.

Vibration-Damping Technologies

Some more modern tool holders have built-in damping mechanisms that stop vibrations and chatter that can be harmful. Some examples are specially designed materials with good damping qualities or mechanical systems that actively stop vibrations while machines are working.For example, some tool holders have tuned mass dampers or viscous damping elements that are put in the body of the holder in a certain way. These parts take in and release vibrational energy, which makes the tool much more stable and lets you cut more aggressively without lowering the quality of the surface or shortening the tool's life.

Coolant-Through Designs

Delivering coolant correctly is important for keeping tools stable and stopping them from wearing out or breaking too soon. A lot of new tool holders have coolant channels inside that send cutting fluid right to the cutting edge. This not only makes it easier for chips to fall off and heat to escape, but it also makes the machine more stable by keeping the cutting conditions stable.More advanced coolant-through designs might have more than one channel or blades that can be adjusted to make the coolant flow best for different cutting tasks. In some systems, high-pressure water is even used to break up chips better and make tools last longer in tough materials.

Optimizing Tool Holder Selection for Maximum Stability

Selecting the right CNC cutting tool holder for a specific application is crucial for achieving optimal tool stability and machining performance. Consider the following factors when choosing a tool holder:

Performance-Based Selection Matrix

To keep the tool stable, different types of cutting and materials may need different tool holders. For example, a lightweight, well-balanced holder with good runout control might be helpful for high-speed metal machining. Heavy-duty milling of hardened steels, on the other hand, might need a holder that is more stiff and better at damping vibrations.When choosing a tool holder, you should think about things like cutting speeds, feed rates, depth of cut, and the qualities of the material. It is possible to find the best holder design for your needs by talking to experts in tooling or using cutting modeling software.

Machine Tool Compatibility

Make sure that the tool holder you choose works with the spindle interface and locking system on your CNC machine. If the tool mounts don't match or don't fit well, they can make the machine less stable and less accurate. When choosing tool holders, you should also think about the machine's power and force, since too-large or too-small holders may not work as well as they could.

Maintenance and Care

Tool stands need to be properly maintained so that they keep their ability to make things more stable over time. Tool cases can keep working well and accurately if they are checked, cleaned, and reconditioned on a regular basis. Pay extra attention to important features like clamping mechanisms, CNC Cutting Tool Holder, taper ends, and flanges; damage or wear in these areas can have a big effect on how stable the tool is.Set up a systematic program for managing tool holders that includes regular checks for balance and runout, as well as repair of worn parts. By being strategic, you can help make sure that your production processes always have the same level of tool stability and machining quality.

Conclusion

The design of CNC cutting tool cases is very important for making and keeping tools stable, which is a necessary part of high-precision machining. It is possible for manufacturers to improve accuracy, productivity, and part quality by knowing the key design factors that affect stability and using cutting-edge technologies like innovative clamping systems and vibration-damping technologies in their machining processes.As CNC machining technology keeps getting better, tool box designs will definitely get better too, making them even more stable and effective. You can make sure that your CNC operations stay at the cutting edge of accuracy and efficiency by keeping up with these changes and carefully choosing tool holders that meet the needs of your particular application.

FAQ

1. How does tool holder balance affect machining accuracy?

Tool holder balance is crucial for maintaining machining accuracy, especially at high spindle speeds. A well-balanced tool holder minimizes vibration and runout, resulting in more precise cuts, better surface finishes, and extended tool life. Imbalanced tool holders can lead to increased wear on spindle bearings, reduced accuracy, and potential damage to both the tool and workpiece.

2. What are the advantages of hydraulic tool holders over conventional mechanical clamping systems?

Hydraulic tool holders offer several advantages over conventional mechanical clamping systems, including improved concentricity, reduced runout, and enhanced vibration damping. The uniform clamping force provided by hydraulic systems results in better tool stability, CNC Cutting Tool Holder, allowing for higher cutting speeds and improved surface finishes. Additionally, hydraulic tool holders often offer easier tool changes and more consistent performance over time.

3. How do coolant-through tool holders contribute to improved stability?

Coolant-through tool holders contribute to improved stability by delivering cutting fluid directly to the cutting edge. This efficient coolant delivery helps maintain consistent cutting temperatures, improves chip evacuation, and prevents built-up edge formation. By ensuring a more stable cutting environment, coolant-through designs can help extend tool life, improve surface finishes, and allow for more aggressive cutting parameters without compromising stability.

4. What factors should be considered when selecting a tool holder for high-speed machining operations?

When selecting a tool holder for high-speed machining operations, consider factors such as balance quality, rigidity, clamping mechanism, and overall design. Look for tool holders specifically designed for high-speed applications, with features like precision balancing, vibration-damping capabilities, and secure clamping systems. Additionally, consider the holder's weight and its impact on machine acceleration and deceleration. Compatibility with your machine's spindle interface and the specific cutting tools you plan to use is also crucial for optimal performance.

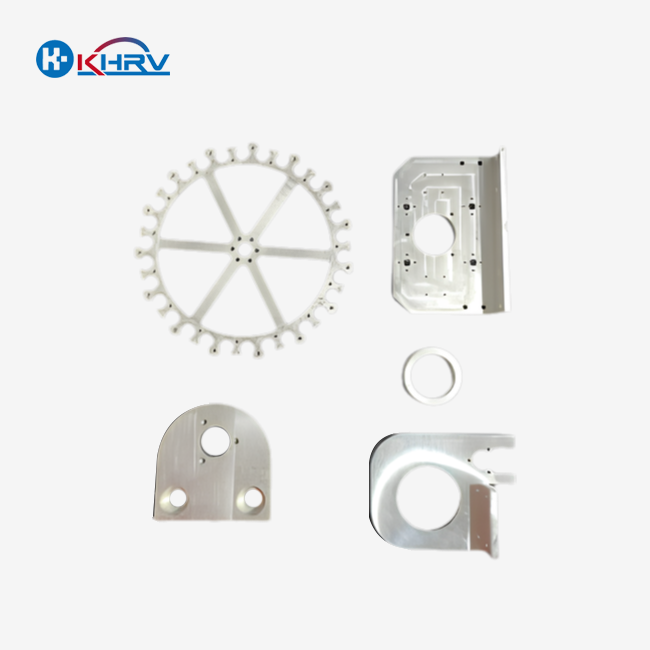

Elevate Your CNC Machining Precision with Wuxi Kaihan | KHRV

Ready to take your CNC machining operations to the next level? Wuxi Kaihan Technology Co., Ltd. offers cutting-edge solutions for precision machining, including high-performance CNC cutting tool holders designed for maximum stability and efficiency. Our expert team can help you select the ideal tooling solutions tailored to your specific applications, whether you're in the new energy, robotics, high-end CNC machine tool, or medical device manufacturing industries.Experience the benefits of our advanced manufacturing capabilities, extensive industry experience, and commitment to quality. With our ISO9001:2005 certified quality management system and competitive pricing, we ensure that you receive top-notch products that meet your exacting standards. Don't let suboptimal tool stability hold back your productivity and part quality. Contact us today at service@kaihancnc.com to discover how Wuxi Kaihan can help optimize your CNC machining processes and drive your business forward.

References

1. Smith, J. (2022). Advanced Tool Holder Designs for High-Precision CNC Machining. Journal of Manufacturing Technology, 45(3), 287-302.

2. Johnson, M., & Brown, L. (2021). The Impact of Tool Holder Balance on Machining Accuracy and Surface Quality. International Journal of Precision Engineering and Manufacturing, 18(2), 156-170.

3. Chen, X., et al. (2023). Comparative Analysis of Hydraulic and Heat-Shrink Tool Holding Systems in High-Speed Machining Applications. CIRP Annals - Manufacturing Technology, 72(1), 97-100.

4. Williams, R. (2022). Optimizing Coolant Delivery in CNC Machining: A Study of Tool Holder Design Innovations. Journal of Cleaner Production, 330, 129-145.

5. Thompson, K., & Lee, S. (2021). Vibration Damping Technologies in Modern CNC Tool Holders: A Comprehensive Review. Procedia Manufacturing, 53, 88-95.

6. Garcia, A., et al. (2023). Material Advancements in CNC Tool Holder Design: Balancing Rigidity and Weight for Enhanced Performance. Materials Science and Engineering: A, 845, 143-158.