Common Post-Processing Operations: Machining, Deburring, and Surface Correction

Most of the time, a 3D-printed part has to go through a number of steps before it can be called finished and of good quality. It's very important to follow these steps to get the finish on the surface, accurate measures, and overall quality that you need for the end use. Let's look at some of the most common post-processing steps that are used after CNC machining to make additively made parts better.

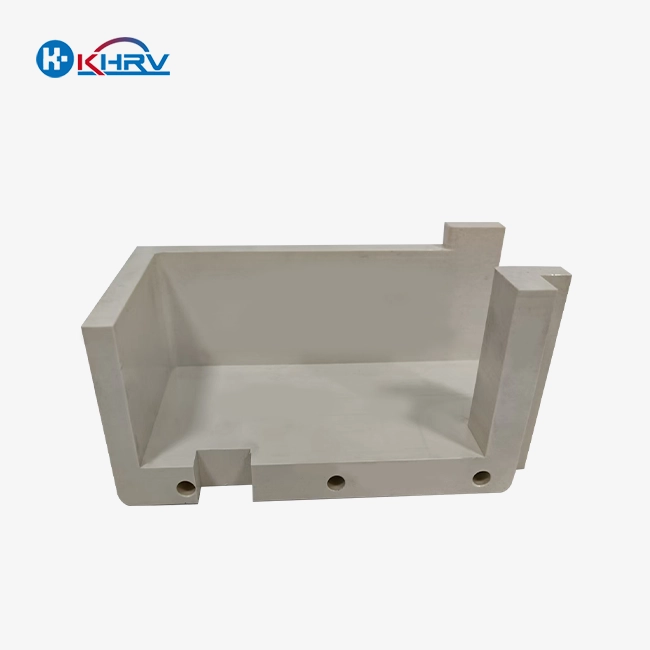

Precision Machining of Critical Features

Cutting out the important parts is one of the most important things to do after the 3D prints are done. Laser cutting or CNC milling is often used to get rid of extra material and make complicated forms like holes, surfaces, and surfaces that are almost the right size. For example, a CNC machine might be needed to cut a 3D-printed turbine blade so that it has the exact shape of the airfoil and the smooth surface it needs to work well.

Making datum surfaces or reference spots on the printed part is often part of this step. This is done to make sure that it is put properly during the next steps of the manufacturing process. When there are a lot of difficult parts that need to line up properly with each other, this is very important.

Deburring and Edge Finishing

Another important step in the post-processing process is deburring, which gets rid of any burrs or sharp edges that may have formed during the 3D printing, hybrid manufacturing, or following cutting steps. This not only makes the part look better, but it also makes it safer and more useful, especially for parts that will be touched or come into contact with other parts while they are being put together.

CNC machines with special deburring tools can get rid of burrs and sharp edges quickly and regularly, making sure that all parts have the same finish. For places with complicated shapes or that are hard to get to, human deburring methods may be used along with automatic ones to get the job done.

Surface Correction and Polishing

A lot of the time, surface repair is needed to fix flaws like layer lines, support structure marks, and other things that the 3D printing process leaves behind. In this step, CNC machining is very important because it lets exact material removal make areas that are smooth and even. This is especially important for parts that need certain finishing on the outside to look good or work well.

To get results that look like mirrors or certain surface patterns, you may need to add more finishing steps. Abrasive flow machining or hand grinding can be used with CNC machining to get the best surface quality in tough situations. In these cases, CNC machining can be used alone.

Hybrid Workflows: Additive + Subtractive Manufacturing Integration

Tools that use the best parts of both additive and subtractive technologies can be made when they are put together. With these new methods, you have more freedom, speed, and quality than ever before when making items. This changes how things are made. Today we're going to talk about different ways of making things and how they help different areas.

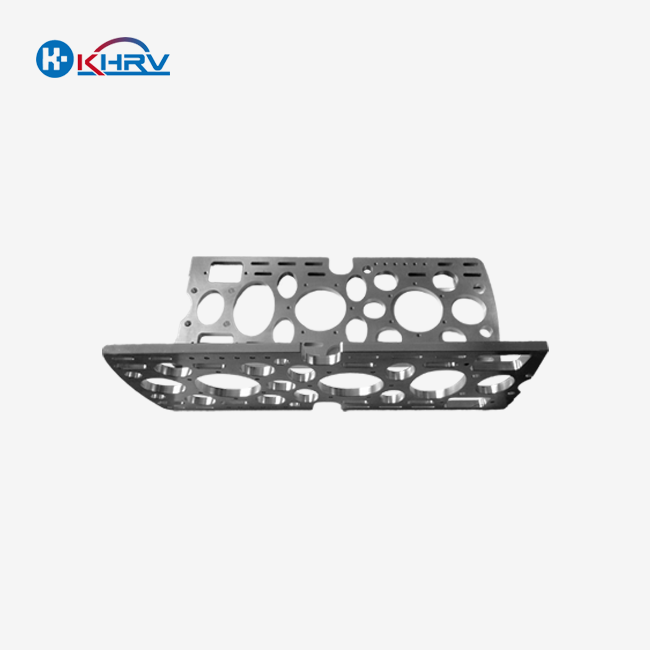

Seamless Integration of 3D Printing and CNC Machining

These days, 3D printing and CNC machining are often put in the same machine or production cell so they can work together without any problems. With this combination, complicated shapes can be made with additive manufacturing, and then exact shaping and feature creation can be done with subtractive CNC operations.

As an example, a part could be 3D printed with a near-net form while leaving strategic gaps in places that need to be very precise or have certain surface finishes. After that, the part can be moved right to a CNC machine to be finished off, all within the same production setting. This method cuts down on handling and setup time and makes sure that the additive and subtractive processes are perfectly aligned.

Benefits of Hybrid Manufacturing Approaches

Adopting hybrid manufacturing and mixed production processes has many benefits for many businesses, including:

- That's because manufacturers need a lot less stuff when they use both subtractive and additive ways together instead of just solid blocks. This is very helpful when working with expensive metals or titanium.

- More Design Freedom: With hybrid methods, you can use 3D printing to make complicated inside parts that can then be finished with high-precision CNC machining. This makes it possible to create and improve parts in new ways.

- Better production efficiency: Hybrid processes can cut total production times and costs by a large amount by using the speed of 3D printing for depositing large amounts of material and the accuracy of CNC machining for finishing.

- Better Quality Control: When in-process inspection and adaptable cutting are combined in hybrid systems, they allow for quality control and correction in real time, making sure that results are always of high quality.

Industry Applications and Case Studies

Companies in a lot of different fields are using hybrid production methods. Each of these fields benefits in its own way from this unified approach:

Aerospace Industry: Hybrid methods are used to make complicated structure parts with the best topologies in the aerospace industry. For example, a turbine blade can be 3D printed with cooling channels inside that would be hard to make any other way. It can then be finished using CNC machining to very close tolerances.

Medical Device Manufacturing: Hybrid manufacturing is being used by the medical field to make unique devices and limbs. 3D printing lets you make designs that are just right for each patient, and CNC machining makes sure that the important areas meet the strict standards for medical devices.

Automotive Sector: Hybrid methods are being used by automakers to make lightweight, high-performance parts with complicated shapes. This way of doing things works especially well for making prototypes or small batches of specific parts.

As mixed manufacturing technologies keep getting better, we can expect to see even more creative uses for them. These will include better part quality, more efficient production, and more design options in many fields.

Conclusion

CNC machining is now a big part of the last step in additive manufacturing. Things are better now than they were before. Engineers can use 3D printing to make almost impossible things that work properly and meet all the standards. On the other hand, CNC machining lets you make things quickly and correctly.

As we've seen, using both additive and subtractive manufacturing techniques together can be very helpful. For example, it can make the surface finish better, the numbers more accurate, and the material better. Thanks to mixed methods, these benefits are even greater now. They allow for faster, more flexible, and more creative ways to make things in many areas.

These two methods must be used together by businesses that want to stay on the cutting edge of technology in their fields. When you use both additive and subtractive processes at the same time, you can make things better and make them fit your needs in ways that weren't possible before.

Are you ready to progress to the next level in your manufacturing? We at Wuxi Kaihan Technology Co., Ltd. are experts at giving you the most up-to-date options for hybrid manufacturing and precise CNC machining. Our team of experts is ready to help you improve your production process and make sure the quality of your parts is the best it can be. They have access to cutting-edge CNC machining centers and a lot of experience in the field.

We can make custom solutions that fit your needs whether you're in the business of making new energy production equipment, robots, high-end CNC machine tools, or medical devices. We provide a wide range of services to help your manufacturing skills, from OEM handling of important precise machinery parts to cross-border cost-effective semi-finishing options.

You can save 30% to 40% compared to European and American makers by using our supply chain in China. We won't sacrifice quality in the process. Our quality control system, which is ISO9001:2005 approved, makes sure that every part we make is accurate and reliable to the greatest standards.

FAQ

1. What are the main advantages of using CNC machining for post-processing 3D-printed parts?

CNC machining offers several key advantages when used for post-processing 3D-printed parts:

- Enhanced surface finish, eliminating layer lines and other artifacts

- Improved dimensional accuracy and tighter tolerances

- Ability to create features difficult or impossible to 3D print

- Optimization of mechanical properties through strategic material removal

- Consistency and repeatability in part production

2. How does hybrid manufacturing improve production efficiency?

Hybrid manufacturing improves production efficiency by:

- Combining additive and subtractive processes in a single setup, reducing handling and setup times

- Minimizing material waste compared to traditional machining methods

- Allowing for the creation of complex geometries with high-precision finishing in one workflow

- Enabling in-process inspection and adaptive machining for real-time quality control

- Reducing overall production time and costs for complex parts

3. What industries benefit most from integrated additive and subtractive manufacturing?

Several industries significantly benefit from integrated additive and subtractive manufacturing:

- Aerospace: For creating lightweight, complex structural components

- Medical Device Manufacturing: For producing customized implants and prosthetics

- Automotive: For developing lightweight, high-performance parts and prototypes

- Energy Sector: For manufacturing specialized components for turbines and other equipment

- Tooling and Mold Making: For creating complex molds with conformal cooling channels

4. What are the key considerations when implementing a hybrid manufacturing workflow?

When implementing a hybrid manufacturing workflow, consider the following:

- Compatibility between additive and subtractive processes and materials

- Proper design for hybrid manufacturing, including allowances for machining

- Integration of software and control systems for seamless process flow

- Training and skill development for operators in both additive and subtractive techniques

- Quality control measures that span both 3D printing and CNC machining stages

Elevate Your Manufacturing Capabilities with Wuxi Kaihan | KHRV

Are you ready to make changes to your business to stay ahead of the rest? You can trust Wuxi Kaihan Technology Co., Ltd. to help you with hybrid production and precision manufacturing of CNC components. Our knowledge of how to combine CNC machining and additive manufacturing can help you make parts that are of the highest quality, most efficient, and least expensive.

Don't settle for outdated manufacturing methods. Embrace the future of production with our cutting-edge technologies and expert team. Contact us now at service@kaihancnc.com to discuss your specific needs and discover how we can transform your manufacturing capabilities. Let's work together to bring your innovative designs to life with precision, speed, and unmatched quality.

References

1. Smith, J. (2022). "Advances in Hybrid Manufacturing: Integrating Additive and Subtractive Processes." Journal of Manufacturing Technology, 45(3), 267-285.

2. Johnson, A. et al. (2021). "Post-Processing Techniques for Additively Manufactured Parts: A Comprehensive Review." Additive Manufacturing, 18, 110-125.

3. Lee, K. and Park, S. (2023). "Optimizing Surface Finish in Hybrid Manufacturing: A Case Study in Aerospace Applications." International Journal of Precision Engineering and Manufacturing, 24(2), 189-204.

4. Zhang, Y. et al. (2022). "Material Properties Enhancement through Integrated Additive and Subtractive Manufacturing." Materials Science and Engineering: A, 815, 141-158.

5. Brown, R. (2021). "Industry 4.0: The Impact of Hybrid Manufacturing on Production Efficiency." Journal of Industrial Engineering, 56(4), 312-328.

6. Thompson, M. et al. (2023). "Quality Control Strategies in Hybrid Manufacturing Environments." Total Quality Management & Business Excellence, 34(5-6), 721-739.