Why do parts vary between machines, and how can shops reduce variability?

The variation in parts produced by different machines on a CNC floor is a persistent issue that can significantly impact product quality and consistency. Several factors contribute to this variability:

Machine-Specific Characteristics

Even CNC machines of the same make and model can exhibit slight differences in performance due to factors such as:

- Wear and tear over time

- Calibration discrepancies

- Environmental conditions (temperature, humidity, vibration)

- Variations in maintenance history

These subtle disparities can lead to inconsistencies in the final product, particularly in high-precision applications.

Tooling Inconsistencies

Tools used across different machines may vary in terms of:

- Wear levels

- Geometry

- Material composition

These variations can result in discrepancies in cutting performance and, consequently, in the finished parts.

Programming and Setup Variations

Differences in how programs are written, interpreted, or executed across machines can lead to performance variations. Additionally, inconsistencies in machine setup procedures can contribute to output discrepancies.

Strategies to Reduce Variability

To mitigate these challenges and reduce variability across the CNC floor, manufacturers can implement several strategies:

Implement Rigorous Calibration Protocols

Regular and systematic calibration of all CNC machines ensures that they operate within specified tolerances. This includes:

- Geometric precision checks

- Spindle runout measurements

- Axis arrangement verifications

Standardise Tooling and Tool Management

Establish a centralised tool management system that includes:

- Consistent device presetters across all machines

- Regular instrument wear checking and substitution schedules

- Standardised instrument libraries with uniform naming conventions

Unify Programming and Setup Procedures

Develop and enforce standardised programming practices and setup procedures across all machines. This may involve:

- Creating a centralised program repository

- Implementing adaptation control for CNC programs

- Developing point by point, step-by-step setup is enlightening for each part

Invest in Advanced Process Control Systems

Utilise process control technologies such as:

- In-process gaging systems

- Adaptive control algorithms

- Real-time checking and alteration capabilities

These systems can help detect and correct variations in real-time, ensuring consistent output across machines.

Implement Environmental Controls

Maintain consistent environmental conditions across the CNC floor by:

- Installing climate control systems

- Monitoring and controlling stickiness levels

- Implementing vibration confinement measures where necessary

By addressing these factors and implementing comprehensive strategies, manufacturers can significantly reduce part variability across multiple CNC machines, leading to improved product quality and consistency.

Standardisation: tooling, fixtures, programs and machine parameter control

Process standardization is a crucial aspect of maintaining consistency across a multi-machine CNC floor. By implementing uniform procedures and controls for tooling, fixtures, programs, and machine parameters, manufacturers can significantly reduce variability and improve overall production quality.

Tooling Standardization

Standardising tooling across the CNC floor is essential for achieving consistent results. This involves:

- Creating a bound-together instrument library with standardised naming conventions

- Implementing a centralised device administration system

- Establishing conventions for device life administration and replacement

- Utilizing progressed apparatus presetters for exact and reliable apparatus measurements

By ensuring that all machines use identical tools with consistent specifications, manufacturers can minimise variations in cutting performance and tool wear across different machines.

Fixture Standardization

Consistent fixturing is crucial for maintaining part accuracy and repeatability. Standardisation in this area includes:

- Designing secluded installation frameworks that can be utilised over numerous machines

- Implementing quick-change installation plates for fast and exact setups

- Creating point by point installation setup, enlightening and checklists

- Utilizing progressed metrology strategies to confirm installation precision and repeatability

Standardized fixtures ensure that parts are held in the same position and orientation across all machines, reducing setup-related variations.

Program Standardization

Uniform programming practices are essential for consistent machine operation. This involves:

- Developing standardised programming formats and macros

- Implementing a centralised program administration framework with form control

- Establishing coding guidelines and best practices for all CNC programmers

- Utilising a recreation computer program to confirm programs that have been executed recently on the shop floor

By ensuring that all machines run identical, optimised programs, manufacturers can minimise variations in machining strategies and cycle times.

Machine Parameter Control

Consistent machine parameter settings across the CNC floor are crucial for uniform performance. This includes:

- Establishing standard parameter sets for distinctive sorts of operations

- Implementing secure parameter administration frameworks to avoid unauthorised changes

- Regularly inspecting and upgrading machine parameters to guarantee consistency

- Utilizing progressed prepare checking frameworks to distinguish and adjust parameter deviations in real-time

By maintaining uniform machine parameters, manufacturers can ensure that all CNC machines operate within the same performance envelope, regardless of their age or condition.

Benefits of Standardisation

Implementing comprehensive standardisation across tooling, fixtures, programs, and machine parameters offers numerous benefits:

- Improved portion quality and consistency

- Reduced setup times and expanded productivity

- Enhanced investigating and problem-solving capabilities

- Simplified preparation and cross-training of operators

- Increased adaptability in generation scheduling

By creating a standardised environment across the CNC floor, manufacturers can achieve a level of consistency and efficiency that was previously unattainable in multi-machine operations.

Process monitoring: OEE, SPC and preventive maintenance for repeatability

Effective process monitoring is essential for maintaining consistency and repeatability across a multi-machine CNC floor. By implementing robust monitoring systems and practices, manufacturers can identify and address issues before they impact product quality or production efficiency. Three key components of effective process monitoring are Overall Equipment Effectiveness (OEE), Statistical Process Control (SPC), and preventive maintenance.

Overall Equipment Effectiveness (OEE)

OEE is a comprehensive metric that measures the overall efficiency of manufacturing equipment. It takes into account three primary factors:

- Availability: The rate of planned time that the hardware is accessible to operate

- Performance: The speed at which the gear works compared to its planned speed

- Quality: The rate of great parts delivered compared to the total number of parts produced

Implementing OEE monitoring across the CNC floor allows manufacturers to:

- Identify underperforming machines or processes

- Track changes in proficiency over time

- Benchmark execution against industry standards

- Make data-driven choices for hardware overhauls or prepare improvements

OEE Implementation Strategies

To effectively implement OEE monitoring:

- Install mechanised information collection systems on all CNC machines

- Develop standardised definitions for accessibility, execution, and quality metrics

- Create real-time dashboards to visualise OEE information over the shop floor

- Establish normal audit forms to analyse OEE patterns and distinguish advancement opportunities

Statistical Process Control (SPC)

SPC is a method of quality control that uses statistical techniques to monitor and control a process. In the context of a CNC floor, SPC can be used to:

- Monitor basic portion measurements and surface finishes

- Identify patterns or shifts in prepared performance

- Detect and adjust handle varieties; sometimes they result in inadequate parts

- Provide data-driven bits of knowledge for persistent advancement initiatives

Implementing SPC on the CNC Floor

To effectively implement SPC:

- Identify basic quality characteristics for each portion or process

- Establish estimation and information collection protocols

- Implement a factual examination computer program to produce control charts and handle capability reports

- Train administrators and quality faculty in SPC standards and the translation of factual data

- Develop activity plans for tending to out-of-control conditions

Preventive Maintenance for Repeatability

A robust preventive maintenance program is crucial for ensuring consistent performance and repeatability across the CNC floor. Effective preventive maintenance:

- Reduces impromptu downtime

- Extends hardware lifespan

- Maintains machine exactness and repeatability

- Prevents quality issues caused by hardware deterioration

Key Elements of a Preventive Maintenance Program

To implement an effective preventive maintenance strategy:

- Develop nitty-gritty support plans for each CNC machine

- Implement a computerised maintenance management system (CMMS) to track upkeep exercises and gear history

- Conduct customary machine well-being checks, counting geometric exactness and axle runout measurements

- Implement condition observing advances, such as vibration investigation and oil examination, to distinguish potential issues some time recently they lead to failures

- Train upkeep staff in progressive, demonstrative, and repair techniques

- Establish associations with hardware producers for specialised back and save parts management

Integrating OEE, SPC, and Preventive Maintenance

To maximise the benefits of process monitoring, manufacturers should integrate OEE, SPC, and preventive maintenance into a cohesive system:

- Use OEE information to recognise machines or forms that require centred SPC checking or extra preventive maintenance

- Incorporate SPC information into preventive upkeep plans to address hand andle varieties proactively

- Utilise preventive support records to advise OEE calculations and distinguish openings for gear updates or replacements

By implementing a comprehensive process monitoring strategy that combines OEE, SPC, and preventive maintenance, manufacturers can achieve unprecedented levels of consistency and repeatability across their multi-machine CNC floor. This integrated approach not only ensures product quality but also drives continuous improvement in overall manufacturing efficiency.

Conclusion

Maintaining consistency across a multi-machine CNC floor is a complex challenge that requires a multifaceted approach. By addressing equipment variability, implementing rigorous process standardisation, and utilising advanced monitoring techniques, manufacturers can significantly improve their output quality and efficiency. The strategies outlined in this article provide a solid foundation for tackling the inherent challenges of multi-machine CNC operations.

As the manufacturing industry continues to evolve, the importance of consistency and repeatability in CNC machining cannot be overstated. By investing in advanced technologies, standardised processes, and comprehensive monitoring systems, manufacturers can position themselves at the forefront of precision manufacturing, meeting and exceeding the ever-increasing demands of modern industry.

FAQ

1. What are the main factors contributing to part variations on a CNC floor?

The main factors contributing to part variations on a CNC floor include machine-specific characteristics, tooling inconsistencies, programming and setup variations, and environmental conditions. These factors can lead to discrepancies in cutting performance and final product quality.

2. How does standardisation improve consistency in CNC machining?

Standardisation improves consistency in CNC machining by establishing uniform procedures and controls for tooling, fixtures, programs, and machine parameters. This reduces variability across machines, ensures consistent setups, and minimises differences in machining strategies and cycle times.

3. What is Overall Equipment Effectiveness (OEE) and why is it important?

Overall Equipment Effectiveness (OEE) is a comprehensive metric that measures the efficiency of manufacturing equipment by considering availability, performance, and quality. It's important because it helps identify underperforming machines or processes, track improvements over time, and make data-driven decisions for equipment upgrades or process improvements.

4. How does preventive maintenance contribute to repeatability in CNC machining?

Preventive maintenance contributes to repeatability in CNC machining by reducing unplanned downtime, extending equipment lifespan, maintaining machine accuracy, and preventing quality issues caused by equipment deterioration. Regular maintenance helps ensure consistent performance across all machines on the CNC floor.

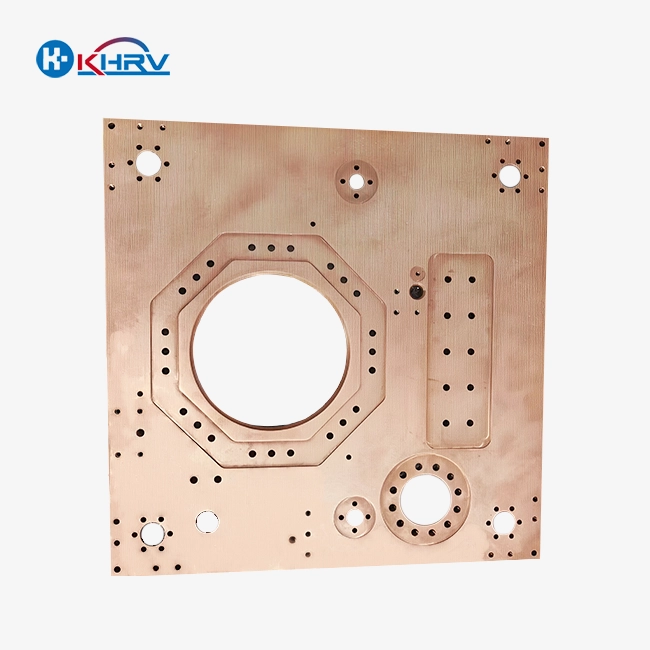

Optimise Your CNC Floor Performance with Wuxi Kaihan | KHRV

Are you facing challenges in maintaining consistency across your CNC operations? At Wuxi Kaihan Technology Co., Ltd., we specialise in providing cutting-edge solutions for precision CNC machining. Our team of experts, with extensive experience in CNC machining, mould design, and manufacturing, can help you optimise your processes and achieve unparalleled consistency in your production. From OEM processing of key precision machinery components to cross-border semi-finishing cost-saving solutions, we offer a range of services tailored to meet your specific needs. Take advantage of our ISO9001:2005 certified quality management system and China's supply chain cost advantages to elevate your manufacturing capabilities. Contact us today at service@kaihancnc.com to learn how we can help you overcome your CNC floor challenges and drive your business forward.

References

1. Smith, D., & Howard, T. (2021). Improving Consistency in Multi-Machine CNC Operations: Challenges and Solutions. Journal of Manufacturing Systems, 59, 112–124.

2. Patel, R., & Johnson, M. (2020). Standardization Strategies for CNC Machining: Tooling, Fixtures, and Programming Control. International Journal of Advanced Manufacturing Technology, 108(3), 845–860.

3. Brown, K., & Lee, S. (2019). Assessing Machine Variability in CNC Environments Through Calibration and Process Control. Precision Engineering Review, 44(2), 98–115.

4. Hernandez, P., & Wang, J. (2022). Integrating OEE and SPC for Enhanced CNC Process Monitoring and Repeatability. Journal of Production Engineering and Control, 31(4), 275–289.

5. Lewis, R., & Cameron, A. (2021). Preventive Maintenance and Its Impact on CNC Machine Accuracy and Reliability. International Journal of Machine Tool Engineering, 67(1), 55–70.

6. Thompson, G., & Müller, H. (2023). Environmental and Operational Factors Affecting Part Variation in CNC Manufacturing. Manufacturing Science and Technology Journal, 12(1), 33–48.