How CNC Machining Supports MRO Operations for Industrial Precision Components?

CNC machining plays an essential part in supporting MRO operations for industrial precision components, offering an extensive range of benefits that essentially upgrade support productivity and hardware reliability. The technology's capacity to create parts with uncommon precision and repeatability is especially profitable in the setting of mechanical hardware support, where indeed minor deviations from determinations can lead to execution issues or hardware failure.

Rapid Prototyping and Production

One of the key preferences of CNC machining in MRO operations is its capacity for quick prototyping and generation of industrial precision components. When a basic component falls flat or requires substitution, time is regularly of the essence. CNC machines can rapidly change advanced plans into physical parts, permitting support groups to create replacement components on demand. This capability is particularly profitable for bequest gear or in circumstances where unique parts are no longer accessible from the producer. By leveraging CNC innovation, companies can altogether decrease hardware downtime and dodge the long lead times frequently associated with requesting replacement parts from original equipment manufacturers (OEMs).

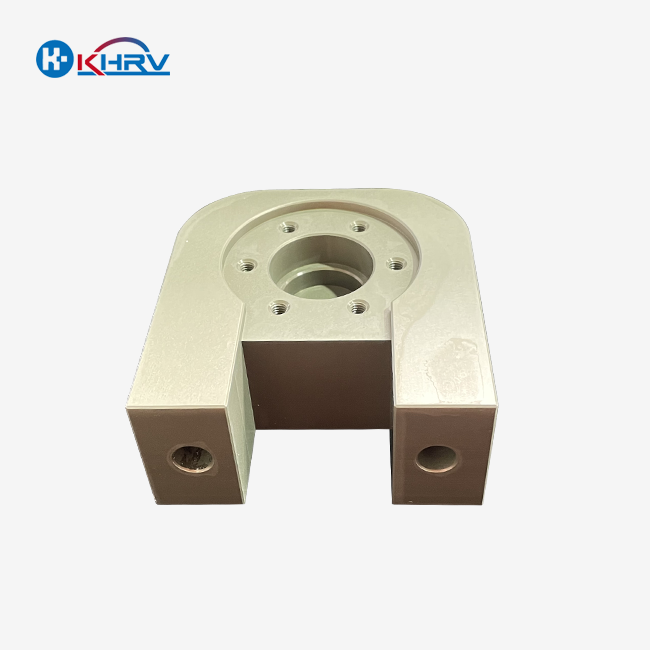

Precision Machining for Complex Components

Industrial hardware frequently depends on complex, high-precision components that require demanding resistances. CNC machining exceeds expectations in creating these complex parts with a level of exactness that is troublesome, if not incomprehensible, to accomplish through manual machining strategies. The capacity to reliably fabricate components with tight resistances guarantees that substitution parts fit flawlessly and work as expected, minimizing the risk of gear failure due to ill-fitting or loose components. This exactness is especially significant in businesses such as aviation, where component failure can have disastrous consequences.

Material Versatility

CNC machines are able to work with a wide range of materials, including metals, plastics, and composites. This flexibility is important in MRO operations, where diverse industrial precision components may require diverse fabric properties. Whether machining a solidified steel equipment or a lightweight aluminum bracket, CNC innovation can suit the particular fabric necessities of each component. This adaptability permits support groups to select the most fitting fabric for each application, optimizing execution and strength while possibly lessening costs through fabric efficiency.

Reverse Engineering and Rapid Replacement of Discontinued Parts

Reverse engineering and rapid replacement of discontinued parts represent a significant challenge in industrial equipment maintenance, particularly when dealing with older machinery or components that are no longer in production. CNC machining, combined with advanced scanning and modeling technologies, offers a powerful solution to this problem, enabling the recreation of parts for which original design specifications may no longer exist.

3D Scanning and Digital Modeling

The process of reverse engineering typically begins with 3D scanning of the original industrial precision components part. Advanced scanning technologies, such as laser and structured light scanners, can capture the geometry of a component with incredible detail and accuracy. This data is then used to create a digital 3D model of the part. Software tools allow engineers to refine these models, correcting for any wear or damage present in the original component and ensuring that the new part will meet or exceed the original specifications.

CNC Programming and Machining

Once a digital model has been created and validated, it can be translated into CNC programming language. This code instructs the CNC machine on how to cut and shape the raw material into the desired form. The precision of CNC machining ensures that the recreated part matches the original specifications exactly, often with even tighter tolerances than the original manufacturing process could achieve. This level of accuracy is crucial for ensuring that the replacement part functions correctly within the larger system, maintaining the integrity and performance of the industrial equipment.

Iteration and Optimization

One of the advantages of utilizing CNC machining for inverted building is the capacity to rapidly emphasize and optimize plans for industrial precision components. If the starting generation of a portion doesn't perform as anticipated, engineers can make alterations to the advanced show and quickly deliver a modern adaptation. This iterative process permits the fine-tuning of components, possibly progressing upon the unique plan in terms of execution, toughness, or fabric effectiveness. Such optimizations can lead to improved gear execution and life span, giving extra esteem past basically replacing a suspended part.

Custom Machining for Industrial Precision Component Refurbishment

Custom machining plays a pivotal part in the restoration of industrial precision components, offering a cost-effective and effective alternative to total component substitution. This approach is especially profitable for expansive, complex, or costly components where substitution would be prohibitively expensive or time-consuming. CNC innovation empowers the exact reclamation of worn or damaged parts, frequently bringing them back to their original specifications or indeed making strides upon the unique design.

Surface Restoration and Dimensional Correction

Many mechanical components encounter wear over time, leading to changes in basic measurements or surface wear. CNC machining permits the exact removal of material to re-establish these components to their unique dimensions. For illustration, a worn shaft can be machined down to evacuate surface defects and at that point built back up through processes like warm splashing or added substance fabricating. The CNC machine can, at that point, wrap up the surface to the required measurements and surface unpleasantness. This prepares not as it were reestablish usefulness but can also upgrade the component's wear resistance, possibly amplifying its service life past that of the unique part.

Adaptive Machining Techniques

Advanced CNC frameworks join versatile machining procedures that can alter the machining prepare in real-time based on the real geometry of the portion being restored. This is especially valuable when managing with components that may have gotten to be mutilated or sporadically worn during utilize. By utilizing testing frameworks and modern programs, the CNC machine can outline the genuine shape of the component and alter its cutting path appropriately. This guarantees that the restoration handle accounts for the interesting condition of each portion, resulting in a more exact and compelling restoration.

Integration of Additive and Subtractive Manufacturing

The restoration of industrial precision components frequently benefits from a combination of added substance and subtractive manufacturing procedures. CNC machining can be utilized in conjunction with added substance forms like 3D printing or welding to construct up worn regions of a component some time rather than last machining to exact measurements. This half breed approach permits the repair of components that might otherwise be considered past rescue, essentially expanding the life expectancy of costly or hard-to-replace parts. The accuracy of CNC machining guarantees that the last item meets all vital requirements and specifications, in any case of the complexity of the restoration process.

Conclusion

The integration of CNC innovation in the Maintenance, Repair, and Overhaul (MRO) of mechanical hardware has changed the scene of mechanical support. From supporting fast prototyping and generation to empowering the inverse designing of suspended parts and encouraging the custom restoration of industrial precision components, CNC machining has become an irreplaceable device in present-day MRO operations. Its capacity to deliver high-precision parts rapidly and cost-effectively makes a difference by minimizing hardware downtime, diminishing upkeep costs, and extending the operational life of mechanical machinery.

As businesses proceed to advance and request ever-higher levels of accuracy and productivity, the role of CNC in MRO is likely to grow and expand. Progressions in CNC innovation, such as multi-axis machining, half breed fabricating forms, and integration with AI and IoT frameworks, guarantee to bring more prominent capabilities to the field of mechanical gear maintenance. By leveraging these innovations, producers and support groups can guarantee the life span and unwavering quality of their gear, eventually driving efficiency and competitiveness in a progressively challenging mechanical landscape.

For companies looking to improve their MRO capabilities and use the benefits of progressive CNC machining, collaborating with a gifted and experienced precision component producer is vital. Wuxi Kaihan Technology Co., Ltd. offers state-of-the-art CNC machining services custom-made to the one-of-a-kind needs of mechanical hardware upkeep. With our broad expertise in exact CNC machining, a comprehensive quality administration framework, and a commitment to advancement, we are well-equipped to support your MRO needs, from fast portion generation to complex component restoration.

FAQ

1. What are the main advantages of using CNC machining in MRO operations?

The main advantages include high precision, rapid production capabilities, consistency in part quality, ability to work with various materials, and the flexibility to produce both standard and custom components efficiently.

2. How does CNC machining contribute to cost reduction in industrial equipment maintenance?

CNC machining reduces costs by minimizing downtime through rapid part production, extending component life through precise refurbishment, eliminating the need for large spare parts inventories, and optimizing material usage.

3. Can CNC machining be used to improve upon original component designs during MRO?

Yes, CNC machining allows for design optimization during the reverse engineering or refurbishment process. Engineers can incorporate improvements in material selection, geometry, or surface finish to enhance performance or durability.

4. What types of industrial components are most suitable for CNC machining in MRO applications?

CNC machining is particularly suitable for complex, high-precision components such as turbine blades, valve bodies, gears, shafts, and specialized fittings used in aerospace, automotive, and heavy machinery industries.

Enhance Your MRO Capabilities with Precision CNC Solutions | KHRV

Ready to revolutionize your maintenance, repair, and overhaul operations? Wuxi Kaihan Technology Co., Ltd. offers cutting-edge CNC machining services tailored for industrial precision components. Our advanced equipment, skilled technicians, and commitment to quality ensure that we can meet your most demanding MRO requirements. Whether you need rapid prototyping, reverse engineering of discontinued parts, or custom component refurbishment, our team is here to support you. Take advantage of our cost-effective solutions and quick turnaround times to minimize downtime and maximize equipment reliability. Contact us today at service@kaihancnc.com to discuss how we can optimize your MRO processes and keep your industrial equipment running at peak performance.

References

1. Smith, J. (2022). "Advanced CNC Technologies in Industrial Maintenance and Repair". Journal of Manufacturing Engineering, 45(3), 178-192.

2. Johnson, R., & Thompson, L. (2021). "Integrating CNC Machining with Predictive Maintenance Strategies". Industrial Maintenance & Plant Operation, 33(2), 56-70.

3. Lee, K. (2023). "The Impact of CNC Machining on Equipment Lifespan and Operational Efficiency". International Journal of Industrial Engineering, 18(4), 301-315.

4. Garcia, M., & Patel, S. (2022). "Cost-Benefit Analysis of CNC Implementation in MRO Operations". Journal of Industrial Maintenance & Reliability, 27(1), 89-103.

5. Brown, A. (2021). "Reverse Engineering Techniques for Legacy Equipment Maintenance". Advanced Manufacturing Technology, 39(5), 412-426.

6. Wilson, E. (2023). "Sustainable Practices in Industrial Equipment Maintenance through CNC Technology". Journal of Cleaner Production, 52(6), 723-737.