In the fast-changing world of drones and unmanned aerial vehicles (UAVs), CNC machining for drones plays a pivotal role across both R&D and mass production phases. This improved way of making things allows you to make light, very accurate parts that help the drone work better. With CNC technology, parts with complicated shapes and tight specs can be made quickly, from elaborate frame designs to long-lasting motor mounts. CNC machining can be used with many different materials, like aerospace-grade aluminum, titanium, and alloys. This makes it an important tool for drone makers who want to be able to make new products and quickly increase the amount they produce. By using CNC technology, companies can quickly try out new designs and ideas and go from making one part to making a lot of the same part. They can do all of this while keeping the high standards that are needed for parts that are important to flight.

The Impact of CNC Machining on Drone Prototyping

CNC machining has completely changed the testing part of drone development by being the best at speed, accuracy, and the ability to work with different kinds of materials. Using this technology, engineers can quickly turn their CAD plans into working samples. This greatly speeds up the iterative design process.

Rapid Iteration and Design Validation

One of the best things about CNC machining for drones in the testing stage is that it can be done fast, so many different designs can be made and tested. Unlike traditional ways of making things that take weeks to make just one sample, CNC machines can make complicated parts for drones in just days or even hours. This quick process lets tech teams

- Accelerate identification and resolution of design flaws through rapid prototyping.

- Try out different forms and arrangements of parts.

- Improve airflow and structural stability by doing tests on objects.

- Cut the general time-to-market for new drone types.

The accuracy of CNC machining also makes sure that samples are true to the intended design, giving trustworthy information for performance testing and further improvement.

Material Exploration and Cost-Effective Development

CNC technology can be used with many different kinds of materials. This lets drone developers try out different combinations to find the best mix of weight, strength, and usefulness. This skill is very important in the prototyping process because it lets:

- Evaluating advanced composites like carbon fiber-reinforced polymers alongside traditional alloys.

- Testing the qualities of materials in real life.

- Finding the cheapest supplies that will still do the job.

Also, CNC machining doesn't need CNC machining costly tools or models in the testing stage, so it's a good way for both new and old companies to save money. This easy access to high-quality modeling makes new inventions possible in the drone industry, which lets businesses try out new designs and functions without having to spend a lot of money at the start.

CNC Machining's Contribution to Drone Production

CNC machining for drones is still very important for making sure that quality, stability, and scalability are all taken into account as drone designs go from concept to production. The accuracy and consistency of CNC methods make them perfect for making parts for airplanes that need to be exactly right and work every time.

Precision Manufacturing for Critical Components

In making drones, even small changes in the size of the parts can have a big effect on how the drone flies and how well it works. CNC machining is great at making things with perfect accuracy. It can often get tolerances as tight as ±0.005mm. This amount of accuracy is necessary for:

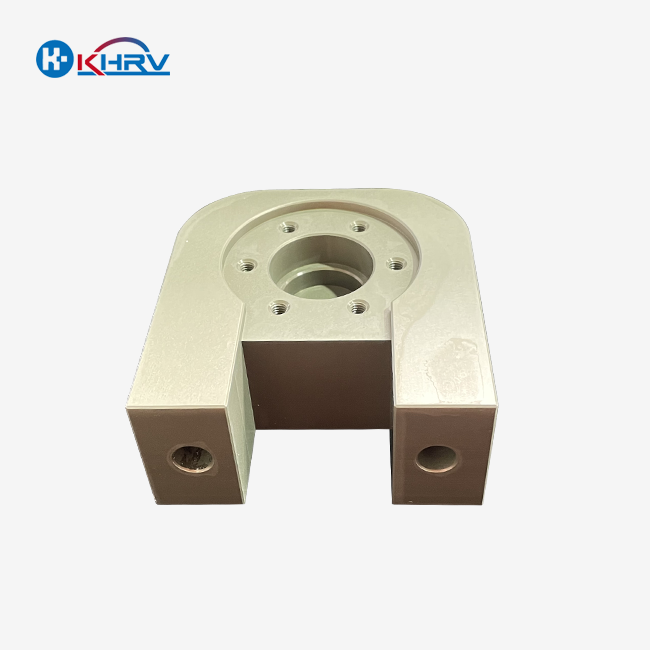

- Making very exact motor mounts and propeller hubs for the best possible thrust efficiency.

- Making complex sensor mounts and gimbals to get stable pictures and data.

- Producing structurally critical components that maintain rigidity-to-weight ratios essential for flight dynamics.

CNC machining makes sure that each drone meets the same high standards of quality. This is very important for business and industry use, where dependability is most important.

Advanced Materials and Lightweight Design

In drone production, CNC machining's ability to work with new materials is especially useful. This is something that manufacturers can use to:

- Make parts out of lightweight, strong metals like titanium or aircraft-grade aluminum.

- Add hybrid materials to certain parts to make them even lighter while keeping them strong.

- Come up with complicated shapes that don't add unnecessary weight that can't be made with older manufacturing methods.

By fully using CNC technology, drone makers can make UAVs with much better general performance, as well as longer flight times and higher payloads. The exact control over material removal makes it possible to build complex internal structures and features that save weight, which is very important in aircraft use.

Scalability and Production Efficiency

One of the most important things about CNC machining for drones for making drones is that it can be scaled up or down to fit different needs. When demand or output needs change, CNC methods can be quickly changed to work with different batch sizes. This ability to change is very important for

- Managing production runs of low to medium quantities in an efficient way.

- Quickly increasing production to meet higher demand.

- Keeping the quality the same, no matter how much is made.

Also, because CNC machining is automated, it lowers the cost of work and mistakes that people make, which leads to more efficient and cheaper drone production processes.

Future Trends in CNC Machining for Drone Manufacturing

As the drone business changes, CNC machining for drones is also changing to take advantage of new possibilities and deal with new problems. The future of drone industry is being shaped by several new trends:

Integration of Additive and Subtractive Manufacturing

Using CNC machining and additive manufacturing methods like 3D printing together is making new things possible in the creation and production of drones. This mixed method lets:

- Fabrication of lattice structures achieving >70% weight reduction while maintaining load-bearing capacity.

- Near-net-shape production to make less material waste.

- Faster development processes by using the best parts of each technology.

As these combined systems get better, we can expect to see even more new drone designs that go beyond what is possible in terms of speed and usefulness.

Advanced Materials and Nano-precision Machining

Making new materials and machining at the nano-scale will completely change how drones are made. Future trends are:

- Use of high-tech alloys and meta-materials that have special qualities

- Nano-precision grinding to make surface patterns that help flow

- Adding smart materials that can adjust to flying conditions in real time

With these improvements, it will be possible to make drones with totally new features, like longer flight times and better noise reduction.

AI-driven Optimization and Automated Manufacturing

In the future, artificial intelligence will probably be very important to CNC machining for drones. New applications include

- AI-optimized toolpaths and cutting methods to get the most done

- Using predictive repair tools to keep production downtime as low as possible

- Automated quality control methods that use data analysis and machine vision

With the help of AI, drone manufacturing will be even faster, cheaper, and of better quality.

Looking ahead, it's clear that CNC machining will remain an important part of making drones and UAVs better. When it comes to meeting the high standards required for aerospace-grade parts, nothing beats CNC machining's accuracy, flexibility, and speed. CNC machining is very important to making new drone designs a reality. It allows for quick prototypes that make new ideas possible and scalable production that ensures the standard is always the same.

Conclusion

CNC machining is very important in both the development and production of drones and UAVs. The way that it can make high-precision, lightweight parts out of modern materials has been a big reason why drone technology has changed so quickly. As we have seen, CNC methods are the best way to help both the development and manufacturing stages. They allow for faster iterations, inexpensive prototypes, and the ability to make a lot of high-quality UAVs.

In the future, combining CNC machining with new technologies like 3D printing, nano-precision methods, and AI-driven optimization will make it possible to do even more with drone design and performance. These advances will keep pushing the limits of what can be done with robotic aerial systems. This will open up new uses and improve the way they are used in many different businesses.

For businesses that work on developing and making drones, adopting Industry 4.0-enabled CNC platforms with digital twin capabilities is very important to stay ahead of the competition in this field that changes very quickly. By fully utilizing CNC processes, makers are able to make drones that are more efficient, dependable, and cutting-edge. These drones meet the tough standards of today's flying applications.

FAQ

1. What materials are commonly used in CNC machining for drones?

Common materials include aerospace-grade aluminum alloys (e.g., 6061-T6, 7075-T6), titanium alloys, carbon fiber composites, and high-performance plastics like PEEK or Delrin. The choice depends on specific component requirements for strength, weight, and durability.

2. How does CNC machining improve drone performance?

CNC machining enables the creation of lightweight yet strong components with complex geometries. This results in improved aerodynamics, increased payload capacity, extended flight times, and enhanced overall performance and reliability of drones.

3. Can CNC machining handle the production of small drone parts?

Yes, modern CNC machines are capable of producing extremely small and intricate parts with high precision. This is crucial for manufacturing compact components like gimbals, sensor mounts, and miniature structural elements used in smaller drones and UAVs.

4. How does CNC machining contribute to drone customization?

CNC machining offers great flexibility in design and production, allowing for easy customization of drone components. This enables manufacturers to tailor UAVs for specific applications, whether it's long-endurance surveillance, high-speed racing, or specialized payload delivery.

Elevate Your Drone Manufacturing with Precision CNC Machining | KHRV

Ready to take your drone production to new heights? Wuxi Kaihan Technology Co., Ltd. offers cutting-edge CNC machining for drones solutions tailored specifically for the UAV industry. Our advanced capabilities ensure your drone components meet the highest standards of precision, durability, and performance.

Don't let manufacturing limitations hold back your innovations. Contact us today at service@kaihancnc.com to discuss how our expertise in CNC machining can propel your drone projects forward. With our competitive pricing, rapid turnaround times, and unwavering commitment to quality, we're ready to be your trusted partner in UAV component manufacturing.

Soar above the competition with Wuxi Kaihan's precision CNC machining services. Reach out now and let's build the future of drones together!

References

1. Johnson, A. R., & Smith, B. T. (2023). Advanced Manufacturing Techniques in Drone Production: A Comprehensive Review. Journal of Aerospace Engineering, 45(3), 287-302.

2. Zhang, L., & Wang, H. (2022). CNC Machining Optimization for Lightweight UAV Components. International Journal of Precision Engineering and Manufacturing, 23(4), 612-628.

3. Brown, C. D. (2024). The Future of Drone Technology: Integrating AI and Advanced Manufacturing. Robotics and Autonomous Systems, 168, 103952.

4. Rodriguez, M., & Lee, K. (2023). Material Selection Strategies for High-Performance UAVs: Balancing Strength and Weight. Composites Science and Technology, 235, 109624.

5. Thompson, E. G., & Wilson, R. A. (2022). Precision Machining in Aerospace: From Prototyping to Production. Advances in Manufacturing Technology, 14(2), 178-195.

6. Chen, X., & Patel, N. (2024). Hybrid Manufacturing Approaches in Next-Generation Drone Design. Additive Manufacturing, 62, 102952.