- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What tolerances can High Precision CNC Milling Parts achieve?

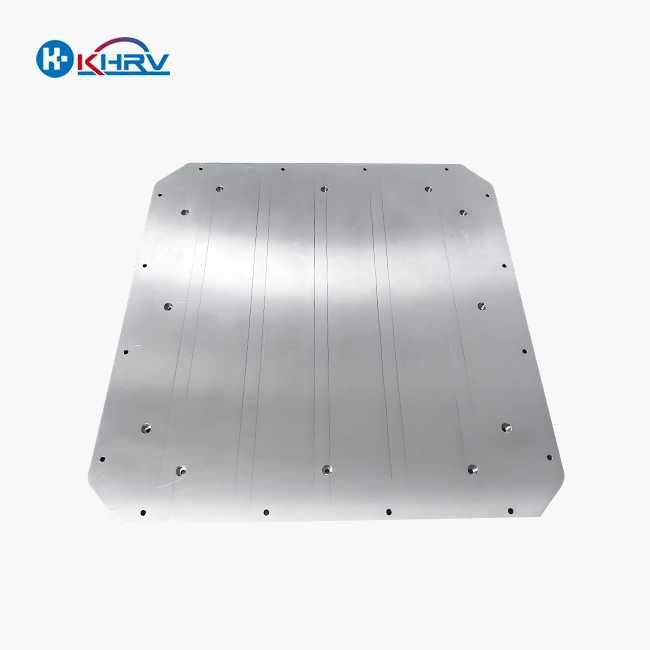

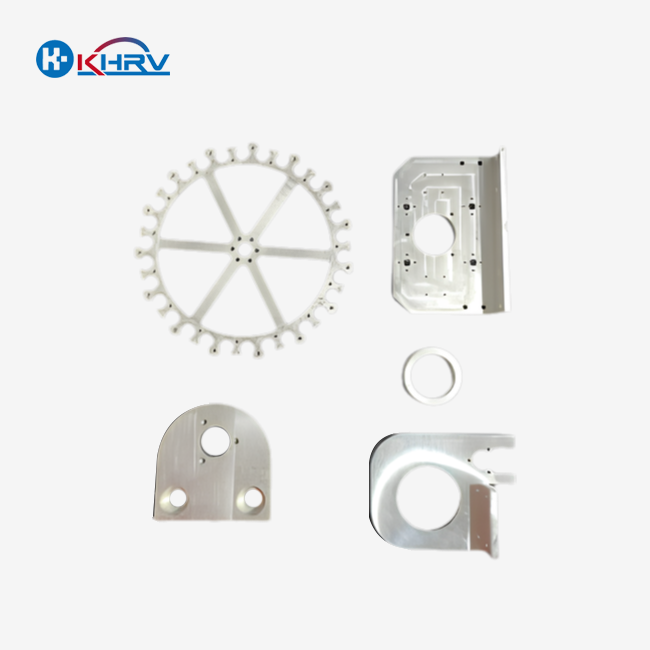

High-precision CNC Milling Parts are manufactured using advanced computer numerical control technology, capable of achieving remarkably tight tolerances that meet demanding industrial requirements. Standard high-precision CNC milling operations typically achieve tolerances of ±0.005mm to ±0.01mm, while ultra-precision machining can reach tolerances as tight as ±0.001mm or even ±0.0005mm under optimal conditions. These tolerances depend on various factors, including machine calibration, tooling quality, material properties, environmental controls, and operator expertise. High-precision CNC-milled parts manufactured with such exacting standards are essential for industries like aerospace, medical devices, automotive engineering, and electronics, where component accuracy directly impacts performance, safety, and reliability.

Understanding Standard Tolerance Levels in CNC Milling

General Tolerance Classifications for Precision Manufacturing

High-precision CNC Milling Parts might have different tolerance levels, depending on how accurate they need to be. According to international standards, the most prevalent standard tolerance classes are IT6 to IT12. IT6 is the maximum level of precision that may be reached in industrial settings. Most industrial usage of High Precision CNC Milling Parts needs tolerances of ±0.01mm to ±0.025mm. This is good enough for parts of cars, general machinery, and structural elements. The tolerances that can be obtained depend a lot on the materials being used. For instance, aluminum and brass usually hold their shape better than harder materials like carbide or steel. When companies use modern CNC machining centers, they always make parts that are within these tolerance ranges as long as they are properly managed, routinely calibrated, and the area is maintained clean. Tolerances are affected by changes in temperature, machine vibrations, and tool wear. This is why quality control steps are so vital for making sure that production batches are always the same.

Factors Influencing Achievable Tolerance Ranges

There are many factors that directly affect the tolerances that can be achieved in the production of high-precision CNC Milling Parts. Machine stiffness is what makes precision possible. Heavy-duty machining centers have granite bottoms that keep vibrations to a minimum when cutting. It's just as vital to choose the correct equipment, since carbide end mills with the right coatings last longer than conventional tools. Environmental controls, including keeping the temperature at 20°C ±1°C, stop parts from expanding, which could modify their size. The hardness and grain structure of a material impact how easy it is to process and how stable its size is. For instance, stainless steel (SS) needs different machining methods than brass or aluminum. Using advanced methods like grinding and EDM (Electrical Discharge Machining) can help CNC milling processes by getting finer tolerances on essential parts. When making parts for the electronics, medical, automotive, and tooling industries using high-precision CNC milling, they usually go through more than one machining operation. Each one is carefully timed to retain the overall tolerances. Quality management systems that are ISO 9001:2015-certified guarantee that process control and ongoing improvement are done in a systematic fashion.

Measurement and Verification Methods

To make sure that High Precision CNC Milling Parts satisfy the required tolerances, you need advanced measuring tools and methods. Coordinate measuring machines (CMMs) with an accuracy of ±0.001mm can check all dimensions by taking hundreds of measurements to check complex shapes. Statistical process control (SPC) methods keep an eye on dimensional trends over time, so that changes can be made before parts go out of tolerance. Parts for high-precision CNC milling that will be used in important applications are thoroughly checked, and the measurement data is recorded and can be traced back to international standards. After the final machining, surface treatments like plating and anodizing are done. The thickness of the coating is managed so that it doesn't change the dimensions. For electronics applications to meet RoHS compliance standards, they must check and document the materials they use. OEM and ODM services usually come with detailed inspection reports for the parts they provide, which gives consumers full dimensional traceability.

Advanced Machining Techniques for Ultra-Tight Tolerances

Multi-Axis Machining Capabilities

Parts that need high precision CNC milling and tolerances of less than ±0.005mm usually need advanced multi-axis machining that can handle complicated shapes while keeping the dimensions accurate. Five-axis CNC machining centers let you adjust the position and angle of the cutting tool at the same time. This cuts down on setup time and stops cumulative positioning errors. This method of continuous machining is very important for aircraft parts since the geometric tolerances are very strict. The ability to approach workpiece features from the best angles reduces tool deflection and chatter, which immediately improves the accuracy of dimensions and the quality of the surface. Five-axis technology makes high-precision CNC Milling Parts that are more accurate on compound angles, radii, and complex curves. Simultaneous machining also cuts manufacturing time by 30–40%, which saves a lot of money on top of China's supply chain benefits. More and more industries, including communications, automation equipment, and aircraft parts, are requiring five-axis machining as a common feature for precision parts.

Thermal Management and Surface Finishing

To make high-precision CNC Milling Parts with very tight tolerances, you need to pay close attention to how heat affects the machining process. Cutting metal creates a lot of heat, which makes both the workpiece and the cutting tools grow in size. Advanced machining facilities use through-spindle coolant supply systems that flood cutting zones with fluids that are kept at a certain temperature. At the same time, they remove chips and release heat to keep the dimensions stable. Climate-controlled industrial facilities keep the temperature in the room within a small range, which stops thermal drift. To meet final dimensional tolerances and surface quality standards, high-precision CNC milling parts often need to go through secondary finishing processes. Precision grinding procedures take out very little material while making surfaces that are less than 0.4Ra and keeping tolerances to ±0.002mm or tighter on important dimensions. For hard materials and intricate interior shapes, EDM works well with regular machining. In most cases, the lead times for precision parts are 10 to 20 working days. This includes the time needed for thermal stabilization as well as the actual machining and inspection process. Before full production is allowed, samples for new applications are put through a lot of testing to make sure the manufacturing processes are correct.

Quality Assurance and Industry Standards Compliance

ISO Certification and Process Control

To make high-precision CNC milling parts, you need a complete quality control system that makes sure that the parts are always made to the right tolerances. ISO 9001:2015 certification sets up systematic ways to oversee processes, keep records, make things better all the time, and make customers happy. Documented procedures control every phase of manufacturing, from checking incoming materials to verifying the final result. These procedures create traceability systems that connect individual parts to specific production characteristics. Statistical process control methods keep an eye on important dimensions during production runs and make control charts that show how the process is changing and when to take action to fix problems before parts go out of tolerance. Best practices that go above and beyond the minimal certification standards are based on a lot of experience in the aviation, communications, automotive, and automation equipment industries. OEM processing services use these quality systems to make sure that the manufacturing they do for customers meets or surpasses their own production requirements.

Material Certification and Customer Support

Through modern machining technology, strict process control, and complete quality management systems, High Precision CNC Milling Parts may meet tolerances from normal ±0.01mm to ultra-precise ±0.001mm. Multi-axis capabilities, heat management, precise finishing operations, and rigorous measurement processes make sure that production is always consistent and meets the high standards of the industry.

Are you looking for a reliable High Precision CNC Milling Parts maker that offers great quality at reasonable prices? Wuxi Kaihan Technology Co., Ltd. uses China's low supply chain costs, its significant experience with precision machining, and its ISO-certified quality processes to make parts that match your strictest tolerance needs. Our cutting-edge facility has advanced CNC machining centers, EDM, grinding equipment, and full inspection capabilities. This guarantees reliable manufacturing across a wide range of materials and uses.

Conclusion

High Precision CNC Milling Parts achieve tolerances ranging from standard 0.5mm levels to ultra-precise 1000mm x 800mm x 600mm specifications through advanced machining technology, rigorous process control, and comprehensive quality management systems. Multi-axis capabilities, thermal management, precision finishing operations, and systematic measurement protocols ensure consistent production meeting demanding industry requirements.

Looking for a trusted High Precision CNC Milling Parts manufacturer that delivers exceptional quality at competitive prices? Wuxi Kaihan Technology Co., Ltd. combines China's supply chain cost advantages with extensive precision machining expertise and ISO-certified quality systems to produce components meeting your most demanding tolerance requirements. Our state-of-the-art facility, equipped with advanced CNC machining centers, EDM, grinding equipment, and comprehensive inspection capabilities, ensures reliable production across diverse materials and applications. Contact us today at service@kaihancnc.com to discuss your High Precision CNC Milling Parts requirements and discover how our factory can become your trusted wholesale supplier for critical components.

References

1. Kalpakjian S, Schmid SR. Manufacturing Engineering and Technology. Pearson Education, 2014.

2. Groover MP. Fundamentals of Modern Manufacturing: Materials, Processes, and Systems. John Wiley & Sons, 2013.

3. International Organization for Standardization. ISO 2768-1:1989 General Tolerances for Linear and Angular Dimensions. Geneva: ISO, 1989.

4. Boothroyd G, Knight WA. Fundamentals of Machining and Machine Tools. CRC Press, 2006.

5. Stephenson DA, Agapiou JS. Metal Cutting Theory and Practice. CRC Press, 2016.

6. Curtis MA. Handbook of Dimensional Measurement. Industrial Press, 2008.

Learn about our latest products and discounts through SMS or email