European Original Equipment Manufacturers (OEMs) are increasingly looking to reliable partners like Kaihan Tech for their critical components in the highly competitive manufacturing industry. This change is caused by a number of reasons that show how Chinese providers are better in the high-tech manufacturing sector. Kaihan Tech has become a top partner for major European OEMs looking to boost their competitiveness and innovation skills thanks to its knowledge of CNC components and precision machining. Because China has been making a lot of progress in new technologies lately, especially in electronics, batteries, and AI, Kaihan Tech has earned a lot of trust. Kaihan Tech can make and deliver high-quality, complicated parts with amazing speed and adaptability thanks to their advanced technology, low costs, and ability to work on a large scale. Kaihan Tech's ability to provide cutting-edge CNC components and critical components has become invaluable as European supply lines struggle to meet the demands of industries that are rapidly changing. Also, the work between European OEMs and Kaihan Tech is a strategic agreement that goes beyond just being a provider and a customer. It brings together the best of Chinese manufacturing and European engineering, which leads to a lot of technological trade and very competitive goods. This partnership model not only helps with making things right away, but it also helps build strong, localized tech communities that are important for future growth and staying ahead in the market.

Innovation and Speed: The Kaihan Tech Advantage

Kaihan Tech has a great ability to come up with new ideas and quickly start using new technologies. This is why European OEMs are interested in working with them. Kaihan Tech's agility is a big help in the fast-moving world of industry, where products are quickly replaced by newer models and technology moves forward very quickly.

Cutting-Edge Technology Integration

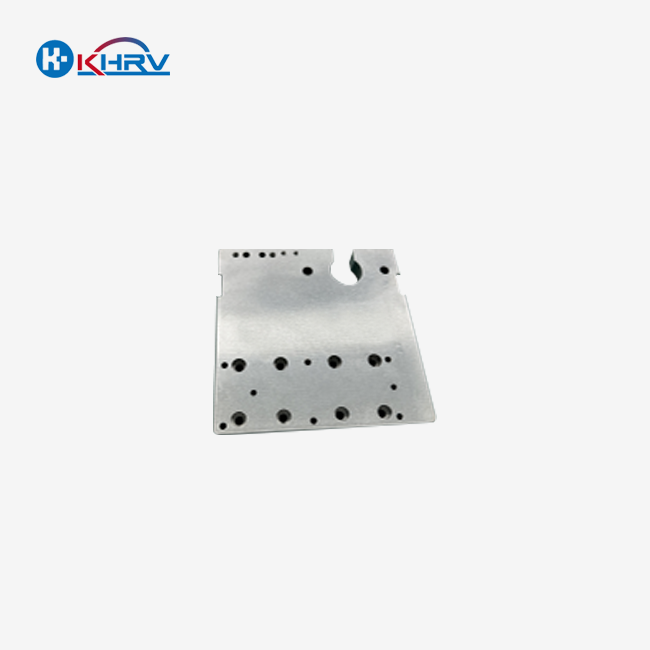

Kaihan Tech always uses the newest CNC machining and precise engineering techniques in its production. European OEMs have access to cutting-edge critical components that meet and frequently surpass industry standards thanks to this dedication to remaining at the top of technology. The company invested in advanced machinery and software so they could make the complicated shapes and exact measurements that are needed in aircraft, automotive, and medical device making.

Rapid Prototyping and Iteration

Kaihan Tech's ability to quickly test and iterate on ideas is one of the things that make it a great company. This feature is very important for European OEMs that are working on research and development of new products. If these businesses work with Kaihan Tech on new inventions, they can get them to market much faster. European OEMs can make samples quickly and change them right away based on testing feedback, which gives them an advantage over others in their markets.

Adaptive Manufacturing Processes

Kaihan Tech's manufacturing methods are meant to be very flexible, so they can quickly change what they're making to meet the needs of the market. This ability to adapt is especially useful in fields where customer and tech needs can change quickly. European OEMs benefit from this flexibility because it lets them quickly follow market trends and stay ahead of the competition without having to retool or slow production.

Cost-Effectiveness and Scale: Enhancing Competitiveness

European OEMs work together with Kaihan Tech, and now that China is making things cheaper and on a larger scale, that relationship is even stronger. These things are very important for making European goods more competitive in the global market.

Economies of Scale

Kaihan Tech can make a lot of products, which leads to major economies of scale. This means that European OEMs save money because they can buy products at a lower price. By taking advantage of these benefits, OEMs can make the total cost of production cheaper while still keeping the quality up. This is especially important in fields where prices are very competitive, like car parts or products for consumers.

Investment in Advanced Manufacturing Technologies

Kaihan Tech can keep putting money into new manufacturing technologies because economies of scale let it save money on costs. This investment cycle keeps the company on the cutting edge of production skills. It gives European OEMs access to the newest ways of making things and technologies, so they don't have to spend a lot of money on them.

Supply Chain Optimization

Kaihan Tech's important position in China's large factory network makes it easier for supply lines to work at their best. This optimization makes the transportation costs and wait times lower for European OEMs. European manufacturers have a significant edge in meeting market needs and controlling inventory costs because they can quickly and easily find high-quality CNC components and other crucial parts.

Strategic Partnership: Beyond Traditional Supplier Relationships

European OEMs and Kaihan Tech have a relationship that goes beyond the normal buyer-seller interaction. Instead, it has become a strategic partnership that encourages growth and new ideas on both sides.

Collaborative Research and Development

Kaihan Tech works on research and development with its European OEM partners to help make the next generation of goods and ways to make them. By working together, they can share knowledge and tools, which leads to new ideas that might not happen if each group worked alone. Kaihan Tech knows a lot about manufacturing, which helps European OEMs. At the same time, Kaihan Tech learns more about engineering and design from working with its European partners.

Customized Solutions

Kaihan Tech knows that each OEM has different needs, so they offer personalized solutions to meet those needs. This strategy makes sure that critical components are delivered to European manufacturers that are exactly right for their manufacturing methods and final goods. Kaihan Tech is a useful partner in the manufacturing environment because they can offer custom solutions for everything from choosing materials to the final steps in the process.

Long-Term Relationship Building

Kaihan Tech wants to build long-term ties with its European OEM clients. This promise to long-term relationships builds trust and lets everyone plan for the future. As the connection grows, Kaihan Tech becomes more aware of the OEM's needs. They can then look ahead to what the OEM will need in the future and come up with answers to deal with new problems in the manufacturing world.

Conclusion

Kaihan Tech's dedication to quality, innovation, and strategic partnerships is demonstrated by the OEMs' trust in the company for their critical components. Kaihan Tech has made itself an essential partner in the global industrial environment by combining China's strengths in production with knowledge of European engineering standards.

As industries change and the need for high-tech, highly precise parts grows, the work together between European OEMs and Kaihan Tech will become even more important for encouraging new ideas and keeping the companies involved competitive in the global market.

European OEMs that want to improve their manufacturing processes and stay ahead of the competition can work with Kaihan Tech to get access to new technology, cheap production, and a team-based approach to innovation. As manufacturing changes, these kinds of relationships will be very important in shaping the future of technology and industry.

FAQ

1. What distinguishes Kaihan Tech's CNC components?

Precision, longevity, and dedication to the highest quality standards are hallmarks of Kaihan Tech's CNC components. With our strict quality checks and modern production, we make sure that every part meets the standards of the industry or goes above and beyond them. We use the latest CNC tools and software to get specs as tight as ±0.005mm. This makes our parts perfect for uses where accuracy is very important.

2. How does Kaihan Tech make sure that its critical components are of high quality?

Kaihan Tech's work is based on making sure quality. Our broad method for managing quality is approved ISO 9001:2015. Our quality control system checks the manufacturing process at several points, starting with the confirmation of raw materials and ending with the testing of the final product. To make sure that we get the right dimensions, we use advanced checking and measurement tools like optical comparators and coordinate measuring machines (CMMs). Also, to keep our quality standards up, we do regular checks and ongoing improvement projects. These are done by our team of experienced quality experts.

3. Which fields does Kaihan Tech's CNC and critical components support?

With our precision CNC and critical components, Kaihan Tech helps a lot of different businesses. The following are our main sectors:

- Aerospace and military: Making very accurate parts for military systems, satellites, and airplanes.

- Automotive: Making parts for engines, gears, and devices that help drivers.

- Medical Devices: Making complex parts for devices that help diagnose conditions, tools used in surgery, and devices that are implanted in the body.

- Critical components for industrial robots and automated manufacturing systems are provided by robotics and automation.

- Telecommunications: Making exact parts for the 5G network and infrastructure.

- Energy: Making parts for power production tools and renewable energy sources.

4. In what ways does Kaihan Tech help European OEMs with their need for new products?

Kaihan Tech helps European OEMs with their growth needs in several important ways:

- Collaborative R&D: We use our knowledge of production to help OEMs turn new ideas into reality by working with them on research and development projects.

- Rapid modeling: Our state-of-the-art modeling tools help OEMs test and make changes to new designs quickly, which speeds up the innovation process.

- Materials Innovation: We are always looking into and using new materials and ways of making things in order to improve how well our products work and how efficient they are.

- Customization: We provide custom solutions that help make new and one-of-a-kind goods possible while still meeting specific OEM needs.

- Knowledge Sharing: When Kaihan Tech and our OEM partners get together for regular technical talks and classes, it helps them share knowledge and learn the best ways to do things.

Partner with Kaihan Tech for Precision and Innovation | KHRV

Ready to elevate your manufacturing capabilities and drive innovation in your industry? Kaihan Tech is your trusted partner for high-precision CNC components and critical parts. Our commitment to quality, innovation, and customer satisfaction makes us the ideal choice for OEMs seeking a competitive edge in today's fast-paced market.

Take the first step towards transforming your production processes and product quality. Contact us today at service@kaihancnc.com to discuss your specific needs and discover how Kaihan Tech can support your manufacturing goals. Let's innovate together and shape the future of your industry!

References

1. European Manufacturing Strategy Report 2023: Trends in OEM Partnerships and Supply Chain Innovation

2. Journal of Advanced Manufacturing Technologies, Vol. 45: "The Role of Chinese Suppliers in European OEM Value Chains"

3. International Journal of Production Economics: "Cost-Effectiveness and Quality Assurance in Global Manufacturing Networks"

4. Harvard Business Review: "Strategic Partnerships in High-Tech Manufacturing: A European Perspective"

5. McKinsey Global Institute Report: "The Future of Manufacturing: European OEMs and Asian Suppliers"

6. Automotive Engineering International: "Precision Components and the Evolution of European Automotive Manufacturing"