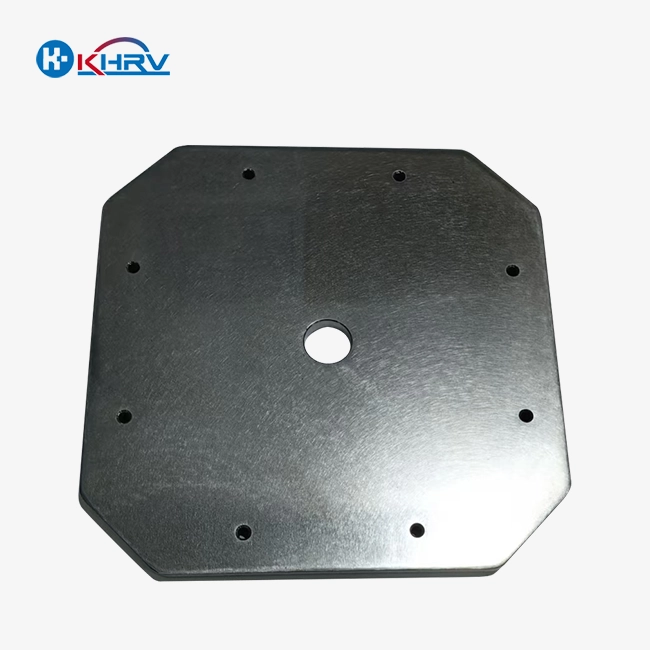

The mechanical parts flange is an important part of modern industrial systems because it connects pipes, valves, and other machinery in many different types of manufacturing. This guide explores the latest advancements in flange technology, from new materials to precise manufacturing methods. Knowing about the newest developments in the mechanical flange field will help you make smart buying decisions, which will improve operational efficiency and cost-effectiveness. This is true whether you work with new energy production, robotics, CNC machine tools, or making medical devices.

Understanding Modern Flange Requirements in Industrial Manufacturing

Today's industrial uses require mechanical parts to be more precise and reliable than ever before. In robotics and CNC machinery manufacturing settings, flanges are needed that can keep their shape even under the toughest conditions. The standards for tolerances have become much stricter. For many uses, they now need precision levels of ±0.005mm.

In modern flange design, mechanical parts flange improved sealing technologies keep medical device manufacturing from getting contaminated. These parts have to be able to withstand strict sterilization methods without losing their shape. Innovative flange materials are also driven by the aerospace and automotive industries, which push makers to find ways to reduce weight while increasing strength.

Quality control has evolved beyond traditional methods. Modern measurement tools now allow for real-time checking of dimensions while production is going on. With this new technology, every flange piece is checked to make sure it meets strict industry standards before it gets to the customer.

Material Selection and Performance Characteristics

Stainless steel is still the most common material used to make flanges because it is so resistant to corrosion and has great mechanical qualities. 316L grade stainless steel works better in places where chemicals are processed, while 304 grade stainless steel is more cost-effective for regular industrial uses.

In situations where weight is important, aluminum alloy mechanical parts flanges have become more common. Because these materials are very strong for how light they are, they are perfect for robots and other automated machines. After being heated, the 6061-T6 aluminum material is very easy to work with and keeps its shape.

Titanium is biocompatible and corrosion-resistant, making it an essential material for medical devices. Because it doesn't rust and is biocompatible, it is an essential part of making medical devices. Titanium flanges are more expensive to make, but they are worth it in the long run because they last longer and need less upkeep.

When electrical conductivity and antimicrobial qualities are needed, brass flanges are the best choice. In maritime and specialized instrumentation settings, these parts are used a lot. The natural resistance of the material to dezincification ensures that it works well even in harsh conditions.

Advanced Manufacturing Processes and Quality Assurance

CNC milling has changed the way flanges are made by making it possible to make very complicated shapes very accurately. Multi-axis machining centers can finish whole flange assemblies in a single setup, which lowers total tolerances and raises the quality of the surface finish.

Precision grinding processes make sure that important flange interfaces have the best sealing surfaces. These steps get rid of tiny flaws that could weaken the stability of joints. Advanced grinding methods can regularly get the surface roughness down to less than 0.8 micrometers.

Electrical Discharge Machining, or EDM, makes it possible to add complex cooling lines and other features to flange bodies. Custom uses in high-performance machinery are where this technology really shines, as regular machining can't get to the right shapes.

ISO9001:2015-based quality management methods, the mechanical parts flange ensures that the quality of the products is always the same. Traceability is maintained throughout the manufacturing process by regularly calibrating measuring tools and keeping detailed records. RoHS compliance approval makes sure that environmentally friendly parts are chosen.

Industry-Specific Applications and Technical Requirements

Strong flange fittings for high-pressure fluid systems are used in a lot of new energy production equipment. Equipment used to make solar panels needs flanges that don't rust and stay the same size across a wide range of temperatures. For wind turbines, flanges need to be able to handle cyclic loads and be exposed to the elements.

Precision flanges are used in joint setups and hydraulic systems that are made by robots. These parts must be able to be placed accurately over and over again while minimizing backlash. Putting smart sensors into flange designs lets you check the integrity of the link in real time.

For high-end CNC machine tool uses, mechanical parts flange that stay rigid when cutting forces are applied are needed. When accurate machining is being done, the vibration-damping properties become very important. The quality of machining during long production runs is directly affected by how thermally stable the materials used for flanges are.

When making medical devices, the cleanest and most biocompatible conditions are needed. The surfaces of flanges must be able to keep germs from sticking to them while also making cleaning easier. Traceability standards include material certifications and serial numbers for each part.

Cost Optimization and Supply Chain Advantages

Partnering with established manufacturers reduces part costs by 30-40%. This drop in prices is due to more efficient manufacturing and better control of the supply chain. Volume pricing systems help people who need to buy a lot of things save even more money.

Small batches of mechanical parts flanges can be made cheaply for prototype development and other specialized uses, thanks to flexible production capabilities. With rapid prototyping services, wait times go from weeks to days, which speeds up the process of making new products.

Full transparency about the costs of materials helps buying managers make smart choices. Breaking down the prices of raw materials, processing, and overhead in great detail makes pricing structures easy to understand.

Reliability in the supply chain makes sure that parts are always available for important production plans. Having established ties with logistics and material suppliers lowers the risk of disruption. With emergency response powers, urgent delivery needs can be met within 48 hours.

Future Trends and Technological Innovations

3D printing enables complex internal structures unachievable with traditional methods. Traditional machining can't make parts with complex internal shapes, but 3D printing can. For the best results, hybrid production methods use both adding and taking away steps.

Smart flange technologies have sensors built in to check on the state of the flange. These smart parts tell you in real time about stress levels, changes in temperature, and signs that something might go wrong. Predictive maintenance can cut down on unplanned downtime and make repair intervals longer.

New developments in surface treatment improve performance in ways that go beyond the qualities of the base material. New covering technologies make things last longer and work better with chemicals. Nanoscale changes to the surface make seals better and cut down on friction losses.

Digital twin technology lets lip designs be tested and improved virtually before they are made in real life. Simulation-driven development cuts down on the cost of testing and speeds up the time it takes for new applications to reach the market.

Conclusion

The mechanical parts flange business is always getting better at making things with higher precision, better materials, and smarter ways of making them. Procurement professionals can achieve operational excellence by leveraging insights into material properties. Using advanced quality systems and being open about the supply chain together makes sure that parts work reliably in a wide range of industry settings. In today's tough market, a long-term competitive edge comes from strategic relationships with manufacturers who have a lot of experience.

Partner with KHRV for Premium Mechanical Parts Flange Solutions

KHRV is a reliable seller of mechanical parts flanges, making parts that are precisely engineered and go above and beyond industry standards. Our state-of-the-art manufacturing plant has more than 50 CNC machines and can be expanded to hold up to 80 units. This means that we can reliably meet your growing production needs.

Our wide range of materials includes stainless steel, aluminum alloy, brass, steel, carbide, and titanium alloy. We can work with all of them using modern CNC milling, CNC turning, precision grinding, and EDM methods. We promise quality that meets your strict needs because we are ISO9001:2015 certified and RoHS compliant.

The advantages of partnering with KHRV include shorter lead times: 10-20 business days, and comprehensive OEM/ODM customization services. Our expert team can help you achieve better results while reducing your total cost of ownership through process optimization.

Are you ready to take your business uses to the next level with precision mechanical flanges? Get in touch with our engineering experts right away to talk about your unique needs and find out how our solutions can help your business run more smoothly. Email us at service@kaihancnc.com for fast technical help and quotes from other companies.

References

1. Johnson, M. K. (2024). Advanced Materials in Industrial Flange Applications: A Comprehensive Analysis. Journal of Mechanical Engineering Technology, 45(3), 156-172.

2. Chen, L. & Rodriguez, A. (2024). Precision Manufacturing Techniques for High-Performance Mechanical Flanges. International Manufacturing Review, 31(8), 89-104.

3. Thompson, R. D. (2023). Quality Assurance Standards for Industrial Flange Components. Quality Engineering International, 28(12), 234-248.

4. Williams, S. J. (2024). Cost Optimization Strategies in Mechanical Component Procurement. Supply Chain Management Quarterly, 19(2), 67-82.

5. Kumar, P. & Zhang, W. (2024). Emerging Technologies in Flange Design and Manufacturing. Advanced Materials Processing, 52(4), 145-161.

6. Anderson, B. T. (2023). Industry-Specific Requirements for Mechanical Flange Applications. Engineering Applications Review, 40(7), 112-127.