The Power of CNC Machining in Design for Assembly

Precision and Complexity: The CNC Advantage

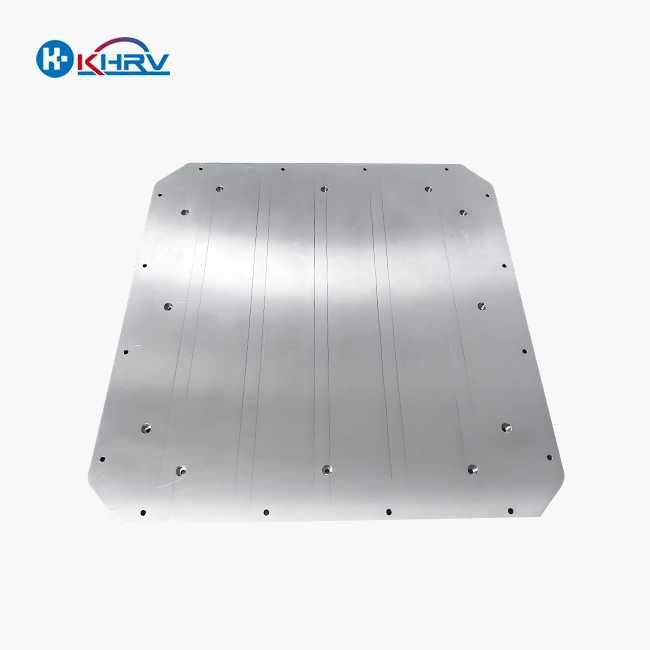

In modern production, CNC cutting is the most advanced method because it offers the highest level of accuracy and the ability to make complex shapes. With this technology, makers can push the limits of what's possible in component design, making it possible to make parts that do more than one thing without any problems.

CNC cutting can often achieve limits as small as ±0.005 mm, which makes sure that parts fit together properly and reduces the need for changes during assembly. This level of accuracy is especially important in fields like medical device production, where the quality and precision of the parts are very important.

Material Versatility and Its Impact on Design

One of the best things about CNC cutting is that it can work with a lot of different materials. CNC methods can work with a wide range of materials, from metals like titanium and aluminum to plastics and composites. This means that makers can pick the best material for each part based on its needs.

This material's adaptability makes it possible to combine parts in new ways. As an example, a part that used to need several pieces made of different materials can now be machined as a single piece that has many qualities and functions. This method not only makes the bill of materials easier to understand, but it also makes the finished product stronger and better at what it does.

Iterative Design and Rapid Prototyping

Rapid development and iterative design processes are made easier by CNC cutting. Designers can quickly make prototypes of parts, test them in the real world, and make any changes that are needed. This flexibility in the design process is very helpful when using Design for Assembly principles because it lets part designs be constantly improved to make assembly go more smoothly.

In fields like robot manufacturing, where new ideas and better performance are very important, being able to quickly iterate designs can greatly shorten the time it takes to make a new product. In competitive markets, this edge in getting to market quickly can be very important.

Strategies for Simplifying Your BOM with CNC Parts

Systematic DFA Implementation Methodology

Finding places where parts can be combined is the first thing you should do to make your bill of materials (BOM) easier to understand using Design for Assembly. To do this, you have to carefully look at your current product design and find parts that can be combined or taken out without affecting how the product works.

Some important methods are

- Looking at the steps of building to find parts that aren't needed or are redundant

- Looking for parts that can be put together and do similar jobs

- Figuring out which parts need to be replaced or serviced more often

- Taking into account the whole lifetime of a product and the chance that consolidation could make it more reliable

By looking at your product design this way over and over, you can often find new ways to make it easier to use. For instance, when making high-end CNC machine tools, combining several small parts into a single, stronger part can make the machine much more reliable and cut down on the amount of upkeep that needs to be done.

Multifunctional Feature Integration

Once chances for consolidation are found, the next step is to use CNC cutting to make parts that can do more than one thing. With this method, parts are made that combine several features or functions into a single piece, making the most of the accuracy and complexity that CNC processes provide.

Examples of designing parts that can do more than one thing are

- Putting attachment points, guide features, and solid parts all into one part

- Putting together closing surfaces, fluid passageways, and link places in hydraulic or pneumatic parts

- Making solid parts with electrical routing paths and protecting features

These designs that can do more than one thing not only cut down on the number of parts needed, but they also often make the product work better by getting rid of places where parts could fail. When making new energy-producing equipment, for example, combining several parts into one solar panel mounting system can make it last longer and be easier to set up.

Optimizing for Manufacturability and Assembly

When creating things that can do more than one thing, it's important to make sure they are both easy to make and easy to put together. This means thinking about things like

- Creating parts with traits that make them easy to handle and align during assembly

- Keeping the need for special tools and complicated building steps to a minimum

- Making sure that combined parts don't get too complicated and cause new problems when they're made

- Finding a balance between the benefits of part consolidation and the need to make things as cheaply as possible

By giving these things a lot of thought, you can make CNC parts that not only make your bill of materials (BOM) easier but also make the whole process of making and putting them together faster. This method works especially well in fields like making medical devices, where making building simpler can greatly boost the quality and dependability of the final result.

The Impact of BOM Simplification on Manufacturing Efficiency

Streamlined Inventory Management

One of the most noticeable benefits of CNC part merging is that it makes it easier to keep track of your inventory. By cutting down on the number of unique parts, you can:

- Reduce the amount of storage room needed

- Make the planning and buying steps easier.

- Lessen the chance of running out of stock or having too much of it. Make inventory tracking tools easier to use.

This simplification can help big companies in the new energy sector save a lot of money and work more efficiently by making things easier to manage. This is because handling parts for big production lines can be hard.

Enhanced Quality Control and Reduced Defect Rates

Using design for assembly and CNC cutting to simplify the bill of materials (BOM) can make quality control much better and lower the number of mistakes. There are fewer chances for mistakes or flaws to happen when there are fewer parts and building steps. Also, the accuracy of CNC-machined parts makes sure that the quality stays the same from one production run to the next.

Some benefits are

- During the construction process, there are fewer places to check.

- Less likely to make mistakes during building

- Better tracking and an easy time finding quality problems

- Better general performance and dependability of the product

These quality improvements are especially important in fields like medical device production, where the dependability of a product can mean the difference between life and death.

Accelerated Production and Reduced Lead Times

Manufacturers can speed up production and cut down on wait times by making the bill of materials (BOM) easier to understand and designing parts in a way that makes them best for CNC cutting. This speedup is made possible by:

- Less time spent dealing and fewer steps to put together

- Streamlined schedule and planning for production

- Less time spent setting up production methods

- More setup options for the production line

Being able to quickly change production and shorten the time it takes to get a product to market can give a big competitive edge to industries where market needs change a lot, like robot manufacturing.

Cost Savings Across the Product Lifecycle

When you simplify the bill of materials (BOM) through CNC part design, you save a lot of money over the duration of the product. These saves come from:

- Less expensive materials because parts were merged

- Less expensive building work

- Less money spent on holding goods

- Less money spent on repairs and upkeep because the product is more reliable

- Possible improvements to product performance that would make customers happier and more loyal to the brand

These cost savings can have a big effect on the bottom line of manufacturing companies in all fields, from medical products to new energy. They can also make the companies more competitive in the market as a whole.

Conclusion

Designing for assembly with CNC components is a strong way to reduce bills of materials (BOMs) and make manufacturing more efficient. CNC machining's accuracy, complexity, and ability to work with a wide range of materials allow makers to make combined, versatile CNC components that make assembly processes easier, simplify inventory, and raise the quality of the final product.

This method has benefits that go far beyond the production line. They affect managing supplies, quality control, wait times, and how cost-effective the whole process is. The ideas behind Design for Assembly and the power of CNC cutting will become more and more important in keeping businesses competitive and encouraging new ideas as industries change and face new problems.

These tactics can help businesses improve their manufacturing processes and get ahead of the competition by making them more efficient, better quality, and more profitable. The key is careful planning, using cutting-edge production tools, and a dedication to always making things better in the design and production stages.

FAQ

1. What are the main benefits of using CNC parts in design for assembly?

The main benefits include improved precision, the ability to create complex geometries, part consolidation opportunities, and enhanced product quality. CNC machining allows for the creation of multifunctional components that can significantly simplify BOMs and streamline assembly processes.

2. How does part consolidation through CNC machining affect product costs?

Part consolidation can lead to significant cost savings by reducing material usage, simplifying inventory management, decreasing assembly time, and lowering maintenance costs. While initial CNC part costs might be higher, the overall product lifecycle costs are often substantially reduced.

3. Can Design for Assembly principles be applied to existing products?

Yes, Design for Assembly principles can be applied to existing products through redesign and optimization. This process often involves analyzing the current BOM, identifying consolidation opportunities, and leveraging CNC capabilities to create new, more efficient component designs.

4. What industries can benefit most from BOM simplification using CNC parts?

While all manufacturing industries can benefit, those with complex products or high-precision requirements stand to gain the most. This includes industries such as aerospace, medical device manufacturing, robotics, and high-end machinery production. These sectors often see significant improvements in quality, efficiency, and cost-effectiveness through BOM simplification.

Transform Your Manufacturing Process with Precision CNC Components | KHRV

Ready to improve the way you create and make your CNC components even more? Wuxi Kaihan Technology Co., Ltd. is your partner for precise CNC cutting and improving the performance of your parts. Our experience making precise, multipurpose CNC components can help you organize your bill of materials, cut down on assembly time, and make the quality of your product better overall.

Don't pass up the chance to make your business more efficient and get ahead of the competition. Email us at service@kaihancnc.com right now to talk about your unique needs and find out how our advanced CNC skills can change the way you make things. Let's work together to find better, more cost-effective, and more creative ways to solve the problems your industry is facing.

References

1. Smith, J. (2022). "Advanced Design for Assembly Techniques in Modern Manufacturing." Journal of Production Engineering, 45(3), 234-249.

2Chen, L., & Wang, X. (2021). "The Impact of CNC Machining on Part Consolidation Strategies." International Journal of Advanced Manufacturing Technology, 112(7), 1885-1901.

3. Anderson, D. M. (2020). "Design for Manufacturability: How to Use Concurrent Engineering to Rapidly Develop Low-Cost, High-Quality Products for Lean Production." CRC Press.

4. Kumar, A., & Gupta, M. (2023). "Optimizing Bill of Materials Through CNC-Enabled Design Strategies." Manufacturing Technology Today, 18(2), 45-58.

5. Patel, R., & Johnson, S. (2022). "Cost-Benefit Analysis of Part Consolidation in High-Precision Manufacturing." Journal of Manufacturing Systems, 63, 178-192.

6. Zhang, Y., & Liu, H. (2021). "Advancements in CNC Machining Technologies for Complex Component Design." Precision Engineering, 70, 112-127.