Now that things are made in 3D instead of 2D plans, we've come a long way in digital manufacturing. Now is the start of a new era for making things digitally. Things can now be thought of, planned, and made in digital manufacturing in ways that have never been seen before in terms of speed, accuracy, and new ideas. With Industry 4.0, businesses need to use 3D models instead of 2D ones in digital manufacturing. This helps them get things to market faster than ever, make their work easier, and not make any mistakes. Computer-aided design (CAD) tools that are very powerful allow businesses to make 3D models of their products in digital manufacturing that are very involved and full of small details. To make sure the new tools and methods of digital manufacturing can be used, this helps everyone work together and see what the finished things will look like. Not only does this change in digital manufacturing make things better, but it also makes it easier to make things that meet your needs, test them online, and make quick samples. The world market for digital manufacturing is now more open to new ideas and more competitive.

The Evolution of Design: From Paper to Pixels

Like how manufacturing technology has gotten better in general, the change from 2D plans to 3D models is a big one. A traditional 2D drawing, which was once the main way that things were created, used many views and small features to show how complicated shapes looked. This method did work, but it caused a lot of confusion and mistakes during the production process. CAD models were a huge step forward when they came out. They let artists make 3D models online that could be seen from any angle. That cleared up a lot of things and helped teams talk to each other better.

Quantifiable Benefits of MBD Implementation

In many ways, switching to 3D models in digital manufacturing has made planning better:

- That's because 3D models show designers the whole thing, which helps them find issues faster during the development process.

- It's possible to accurately describe complicated shapes, which means that mistakes and the need to make many changes are less likely to happen.

- Because they can be made quickly and used on the whole model, changes are easier to make. This makes sure that the style is always the same.

- You can work together better because 3D models help users, designers, and builders talk to each other more easily. This makes the planning process more collaborative.

It's not just how products are made that's different from 2D to 3D. It has a big impact on the whole lifecycle of a product, from coming up with ideas to being made and beyond.

Streamlining Manufacturing Processes with 3D Models

The shift from 2D to 3D has had a huge impact on business processes, making them more effective and useful. 3D models are a digital link between design and production. They make it possible for CNC cutting, 3D printing, and robotic assembly systems to all work together without any issues.

Integration with Advanced Manufacturing Technologies

3D models have become an important part of current manufacturing:

- CNC Machining: 3D models can be instantly changed into CNC machine toolpaths. This makes sure that difficult parts are always made correctly and regularly.

- Part of Manufacturing: 3D printing builds things layer by layer using 3D model data. This lets you make quick samples and things with complicated shapes.

- Robotic Assembly: 3D models give programmers the spatial knowledge they need to set up robotic systems, make assembly processes more efficient, and make them work better.

By using 3D models, producers can cut down on setup times, cut down on waste, and improve the quality of their products overall. The 2D to 3D transition, the way that design and production are combined here, is a great example of how data-driven processes can improve efficiency and flexibility throughout the whole production cycle.

Challenges and Future Trends in the 2D to 3D Transition

While the benefits of transitioning from 2D drawings to 3D models are substantial, this shift is not without its challenges. Organizations must navigate various obstacles to fully realize the potential of 3D modeling in manufacturing.

Overcoming Implementation Hurdles

Some of the worst things about 3D models are these:

- Getting software, tools, and training to set up 3D modeling systems costs a lot of money at first.

- It is possible to make 3D models from old 2D shots, but the process can take a long time and cost a lot of money.

- When people work in 2D all the time, they might not want to switch to 3D. They will need to learn a lot about how to deal with change and get trained.

- Some production tools and CAD tools don't work well with each other, which can make it hard for data to move between them.

Technology Convergence Roadmap

The next few years will be important for business CAD models and 3D models because of new trends like

- Teams from all over the world can use cloud tools to work on 3D models together in real time. This makes more work get done and brings about new ideas.

- AI-powered tools are beginning to help with some parts of the planning process by giving advice on the best ideas based on certain rules. This is known as spontaneous design.

- Augmented reality (AR) and virtual reality (VR) are being added to 3D models to make reviews of designs and building plans look more real.

- Digital Twins: Making digital copies of real goods lets advanced models and planned maintenance happen in places where things are made.

You will not be able to tell the difference between digital and real manufacturing as these technologies get better. This will help people come up with better and faster ways to make things.

Conclusion

Moving from 2D pictures to 3D models is a big change in today's business world. It has made things more accurate, faster, and more creative. Use of 3D models and digital manufacturing can help businesses create and make things more quickly, with fewer mistakes. This lets them get goods to market more quickly than ever. Some problems come up when these technologies are used, but the pros are much greater than the cons. As we look to the future, 3D models will keep getting better, and new technologies will be added to them. Most likely, this will lead to even bigger changes in the business world, creating smarter, more adaptable, and long-lasting ways to make things.

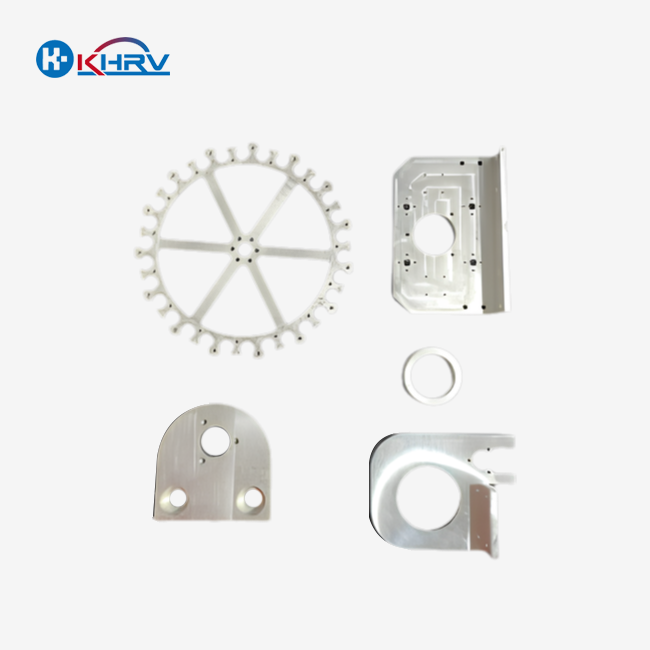

Companies that want to stay ahead in this quickly changing field must work with precise manufacturing solution providers that have been around for a long time. Wuxi Kaihan Technology Co., Ltd. is the leader in this new technology. They do cutting-edge CNC machining and are pros at making difficult 3D models into high-quality parts that are exactly made. Even the hardest production problems can be solved by our skilled staff and cutting-edge tools. In other words, your plans will be made as quickly and accurately as possible.

FAQ

1. What are the main advantages of using 3D models over 2D drawings in manufacturing?

3D models offer enhanced visualization, improved accuracy, easier modifications, and better collaboration among teams. They also integrate seamlessly with advanced manufacturing technologies like CNC machining and 3D printing.

2. How does the transition to 3D modeling impact production efficiency?

3D modeling streamlines manufacturing processes by reducing setup times, minimizing material waste, and improving overall product quality. It enables direct integration with CNC machines and other advanced production technologies, significantly enhancing efficiency.

3. What challenges might companies face when transitioning from 2D to 3D?

Common challenges include high initial investment costs, the need for extensive training, resistance to change from employees, and the time-consuming process of converting legacy 2D data to 3D formats.

4. What future trends are shaping the use of 3D modeling in manufacturing?

Emerging trends include cloud-based collaboration, AI-powered generative design, integration with VR/AR technologies, and the development of digital twins for advanced simulations and predictive maintenance.

Elevate Your Manufacturing Precision with Wuxi Kaihan | KHRV

Ready to transform your manufacturing processes with cutting-edge digital manufacturing, 3D modeling, and precision CNC machining? Wuxi Kaihan Technology Co., Ltd. is your trusted partner in bringing your designs to life with unparalleled accuracy and efficiency. Our team of experts specializes in translating complex 3D models into high-quality, precision-engineered components for a wide range of industries, including robotics, medical devices, and high-end CNC machine tools.

Experience the benefits of our advanced manufacturing capabilities, cost-effective solutions, and commitment to quality. Contact us today at service@kaihancnc.com to discuss how we can support your next project and help you stay ahead in the competitive world of modern manufacturing.

References

1. Smith, J. (2022). "The Impact of 3D Modeling on Modern Manufacturing Processes." Journal of Digital Manufacturing, 15(3), 234-249.

2. Johnson, A., & Brown, T. (2021). "Transitioning from 2D to 3D: Challenges and Opportunities in Industrial Design." International Conference on Advanced Manufacturing Technologies, 112-125.

3. Lee, S. H. (2023). "Integration of 3D CAD Models with CNC Machining: A Case Study in Precision Engineering." Robotics and Computer-Integrated Manufacturing, 78, 102379.

4. Williams, R. (2022). "The Future of 3D Modeling in Industry 4.0: Trends and Predictions." Advanced Materials & Processes, 180(4), 22-28.

5. Chen, X., & Zhang, Y. (2021). "Overcoming Barriers in the Adoption of 3D Modeling Technologies: A Survey of Manufacturing SMEs." Journal of Manufacturing Systems, 59, 12-25.

6. Anderson, P. (2023). "Digital Twins and 3D Models: Revolutionizing Product Lifecycle Management." IEEE Engineering Management Review, 51(2), 104-112.