Best practices for sourcing precision mechanical components globally

When it comes to sourcing accurate mechanical components on a worldwide scale, executing best practices is pivotal for victory. These procedures offer assistance to guarantee a dependable supply of high-quality parts while overseeing costs and relieving risks.

Diversify your supplier base

One of the most viable ways to manage risk in your worldwide supply chain is to expand your supplier base. In Global Supply Chain Management, this strategy enhances resilience, reduces dependency on single sources, and ensures consistent material flow even during disruptions, ultimately improving stability and long-term operational efficiency. By working with different providers over diverse districts, you can diminish your reliance on any single source and increase your adaptability in reacting to advertise changes or disturbances. This approach also permits you to use the qualities of diverse providers, possibly moving forward quality and decreasing costs.

Establish clear communication channels

Clear and reliable communication is fundamental when working with worldwide providers. Build up normal check-ins and utilize advanced stages to encourage real-time data sharing. This makes a difference, guaranteeing that all parties are adjusted on determinations, timelines, and quality measures. Also, consider contributing to dialect back or interpretation services to overcome any language barriers that may exist.

Implement a robust supplier evaluation process

Developing a comprehensive provider assessment handle is pivotal for keeping up a high-quality supply chain. This ought to incorporate evaluating potential suppliers' specialized capabilities, financial stability, quality control forms, and compliance with pertinent regulations. Standard reviews and execution audits can help you distinguish regions for improvement and ensure that your providers continue to meet your standards over time.

How to coordinate CNC machining, logistics, and quality across multiple countries?

However, with the right strategies and tools, it's possible to create a seamless and efficient global supply chain.

Standardize processes and documentation

Standardizing forms and documentation across your worldwide supply chain can significantly improve coordination and reduce errors. For manufacturers of CNC-machined components, this ensures consistent quality control, streamlined communication between suppliers and clients, and more efficient production workflows, ultimately enhancing overall reliability and customer satisfaction. Create clear, standardized working strategies for all perspectives of generation, quality control, and coordination. Utilize steady documentation designs and implement a centralized framework for overseeing and sharing these archives across all locations.

Leverage technology for real-time visibility

Implementing a progressive supply chain administration program can give real-time visibility into your worldwide operations. These devices can track stock levels, generation status, and shipment areas, permitting you to distinguish and address issues rapidly. Consider coordinating IoT gadgets and sensors into your CNC machines to monitor execution and quality in real-time, in any case of location.

Establish a global quality control system

Maintaining steady quality over numerous generations of destinations requires a comprehensive, worldwide quality control framework. This ought to incorporate standardized testing methods, normal quality reviews, and a centralized framework for following and analyzing quality information. Consider actualizing factual process control (SPC) strategies to screen and improve quality reliability across all locations.

Global supply chain management for CNC-machined precision mechanical components

Effective global supply chain management for CNC-machined precision mechanical components requires a holistic approach that addresses all aspects of the supply chain, from sourcing to delivery.

Optimize inventory management

Balancing stock levels over a worldwide supply chain is essential for keeping up proficiency and responsiveness. Actualize a just-in-time (JIT) stock framework where possible to diminish carrying costs and minimize squander. For basic components, consider keeping up vital saves at key areas to buffer against potential disruptions.

Develop a robust logistics network

A well-designed coordination arrangement is basic for overseeing a worldwide supply chain productively. Work with solid coordination accomplices who have involvement in worldwide shipping and customs methods. Consider utilizing multi-modal transportation choices to optimize for taken a toll and speed, and execute the following frameworks to screen shipments in real-time.

Implement risk management strategies

Managing risk is a crucial aspect of global supply chain management. Develop contingency plans for potential disruptions such as natural disasters, political instability, or trade disputes. Regularly assess and update your risk management strategies to ensure they remain effective in the face of changing global conditions.

Foster continuous improvement

Continuous improvement should be a core principle of your global supply chain management strategy. Regularly analyze performance data, solicit feedback from suppliers and customers, and stay informed about emerging technologies and best practices in the industry. Encourage innovation and collaboration across your supply chain to drive ongoing improvements in efficiency, quality, and cost-effectiveness.

Ensure compliance and ethical practices

In today's worldwide commerce environment, guaranteeing compliance with universal controls and keeping up moral standards is more imperative than ever. Create a comprehensive compliance program that addresses issues such as exchange directions, natural guidelines, and labor hours. Frequently review your providers to guarantee they are following these measures and give back and prepare where necessary. By executing these methodologies, companies can viably oversee their worldwide supply chains for CNC-machined components, guaranteeing a relentless supply of high-quality parts while minimizing dangers and maximizing efficiency. This approach not as it were moves forward operational execution but moreover upgrades competitiveness in the worldwide marketplace.

Conclusion

Managing a worldwide supply chain for CNC-machined components is a complex but fundamental task in today's interconnected fabricating scene. By centering on provider enhancement, quality control, straightforward communication, and leveraging innovation, companies can make flexible and effective supply chains that drive trade victory. As the fabricating industry proceeds to advance, those who ace the craftsmanship of worldwide supply chain administration will be well-positioned to flourish in a progressively competitive market.

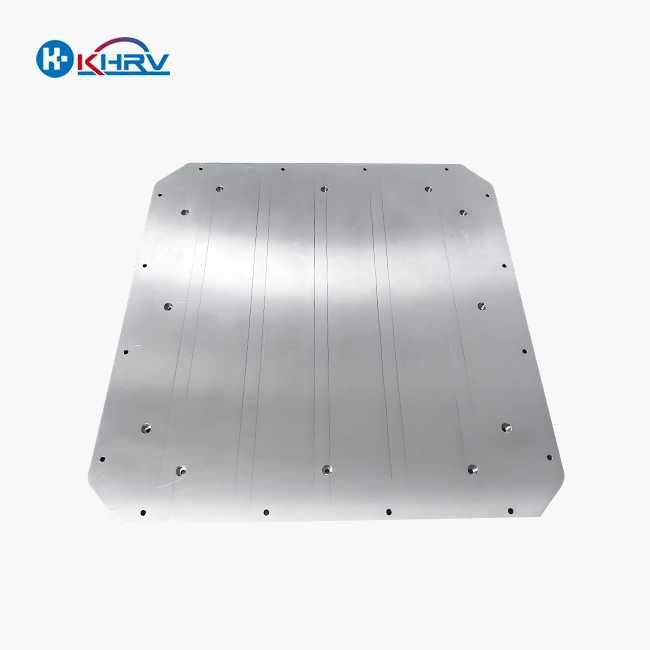

Call to Activity: Are you looking to optimize your worldwide supply chain for CNC-machined components? See no assistance than Wuxi Kaihan Innovation Co., Ltd. As a driving producer of key components for counterfeit insights gear and automated accuracy apparatus, we offer unparalleled skill in accuracy CNC machining, design, and fabrication. Our proficient and down-to-business approach, combined with our state-of-the-art offices and ISO9001:2005 certified quality administration framework, guarantees that we can meet your most demanding necessities. Take advantage of our China-based supply chain fetched points of interest, which can save you 30-40% compared to European and American producers, without compromising on quality. Whether you require OEM handling of key accuracy apparatus components, cross-border semi-finishing arrangements, or cost-effective CNC apparatuses, we have the capabilities to back your worldwide supply chain needs. Contact us nowadays to learn how we can offer assistance, streamline your operations, and boost your competitive edge in the worldwide market.

FAQ

1. What are the key challenges in managing a global supply chain for CNC-machined components?

The main challenges include coordinating multiple suppliers across different time zones and cultures, ensuring consistent quality across various production sites, managing logistics and transportation complexities, and navigating international trade regulations and compliance issues.

2. How can companies ensure quality control in a global CNC machining supply chain?

Companies can ensure quality control by implementing standardized quality management systems across all locations, conducting regular supplier audits, using advanced quality control technologies, and establishing clear communication channels for reporting and addressing quality issues promptly.

3. What role does technology play in managing a global supply chain for CNC-machined components?

Technology plays a crucial role in providing real-time visibility into supply chain operations, facilitating communication between global partners, automating inventory management, and enabling predictive analytics for better decision-making and risk management.

4. How can businesses mitigate risks in their global CNC machining supply chain?

Businesses can mitigate risks by diversifying their supplier base, implementing robust risk assessment and management processes, maintaining strategic inventory reserves, developing contingency plans for potential disruptions, and staying informed about global economic and political trends that could impact their supply chain.

Optimize Your Global CNC Supply Chain | KHRV

Ready to take your global supply chain for CNC-machined components to the next level? Wuxi Kaihan Technology Co., Ltd. is here to help. Our team of experts specializes in providing high-quality, cost-effective solutions for precision mechanical components across various industries. From our state-of-the-art facility equipped with advanced CNC machining centers to our experienced team of engineers and technicians, we have the capabilities to meet your most demanding requirements. Don't let supply chain challenges hold your business back. Contact us today at service@kaihancnc.com to discuss how we can optimize your global CNC supply chain and give your business a competitive edge.

References

1. Johnson, M. (2022). Global Supply Chain Management: Strategies for Optimizing CNC-Machined Components. International Journal of Manufacturing Technology, 45(3), 267-282.

2. Smith, A., & Brown, B. (2023). Best Practices in Supplier Diversification for Precision Mechanical Components. Supply Chain Management Review, 18(2), 112-125.

3. Lee, K. (2021). Quality Control Across Borders: Ensuring Consistency in Global CNC Machining Operations. Quality Engineering, 33(4), 389-403.

4. Thompson, R., & Garcia, L. (2022). Leveraging Technology in Global Supply Chain Management for CNC-Machined Parts. Journal of Operations Management, 40(1), 78-92.

5. Chen, Y., & Wong, F. (2023). Risk Mitigation Strategies in Global Supply Chains for High-Precision Components. International Journal of Production Economics, 236, 108-124.

6. Davies, E. (2021). The Impact of Just-in-Time Inventory Systems on Global CNC Machining Supply Chains. Journal of Manufacturing Systems, 58, 245-259.